Treating Tablets Like Tools

Industrial vending systems keep cutting tools and other items organized. Why not mobile devices, too?

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Portable electronic devices such as laptops and tablets are becoming more common on the shop floor. These mobile devices are increasingly being used as resources for data collection, problem documentation, calculations and reference information, among other things. (For more on the expanding use of tablets in manufacturing, see this commentary.)

The fact that tablets and laptops are not tied down to a particular workstation and can go wherever needed is their strength. But mobility also has the potential to be a weakness. Devices set loose on the floor can easily go missing, become damaged or fall behind on important updates.

One solution for this problem is to treat the technology as another tool—literally. Storing devices in a crib just like drills and milling cutters makes it easier to keep track of the fleet, protect devices when they are not in use, and perform important tasks like charging and software upgrades.

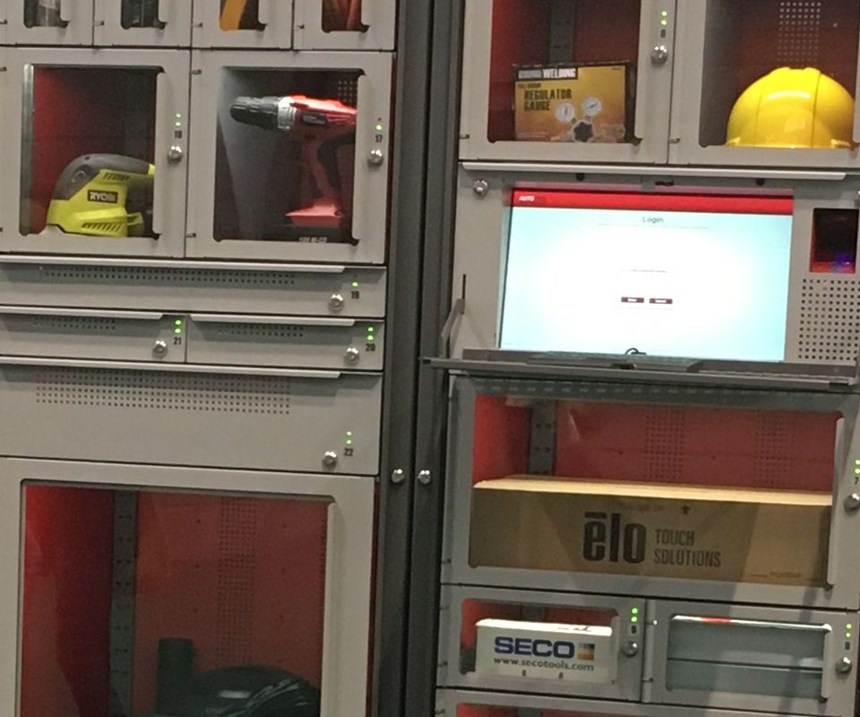

Industrial vending solution provider AutoCrib had this in mind in creating the AutoLocker FX locker-based system. Inspired by the design of server racks used in the IT world, the system consists of a metal locker frame on caster wheels that holds modular storage compartments arranged according to customer requirements. The compartments are offered in 12 different sizes in height increments of 3 inches (8 cm), with several widths available. Each is 24 inches (61 cm) deep. They can be further customized with features such as internal dividers, button systems and weight sensors, as needed.

This makes for a good storage solution for cutting tools, gloves and other consumables, but it’s also possible to equip individual compartments with 110-V power, individual cooling fans and filtration systems, and multistate status lights to support the storage of tablets and laptops. These additions create a safe, clean and cool location for devices to charge while enabling any employee to see at a glance which devices are charging or available by the status lights. The AutoLocker FX also supports managed switched systems, meaning that it’s even possible to push out operating system updates and virus definitions to devices docked inside.

Even with these upgrades, the AutoLocker FX still remains flexible enough to swap compartments in and out as needed. The lockers’ rack-mounted, modular setup means that compartments are easy to rewire in case of a change in the layout. During installation or reconfiguring, each unit is located with two dowel pins on the back and secured with bolts. From there, it’s simply a matter of hooking up the cables and reprogramming the control.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=150)