Top Shops 2013: Davan Manufacturing

Learn about this year’s Machining Technology Honors Program Winner and its approach to capital equipment purchases.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Realizing Success by Applying Advanced Equipment

Davan Manufacturing, located in Washington, Pennsylvania, is this year’s Machining Technology Honors Program Winner. Mark Vanistendael, company president, says he has continued the approach to integrating advanced machining equipment that his father successfully applied.

David Vanistendael started the business in 1968. Over the years, the shop was an early adopter of leading technology as it became available, including NC and CNC machines as well as horizontal machining centers even though this required a significant investment in capital equipment. The approach gave the small shop a competitive advantage over others that used more traditional equipment.

Since Mark took over the company in 1996, the shop has focused on integrating equipment that enables parts to be completed in one setup. This has set Davan Manufacturing apart from others and helped it do more with fewer employees. This is important because the shop is located where there is a heavy concentration of manufacturers with a very competitive labor market. It’s challenging to draw quality, new employees, so the shop leverages machining technology that can perform multiple operations.

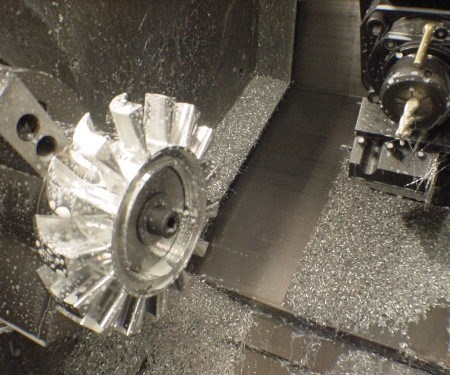

Key to this has been integrating turning centers with live tooling and C-axis positioning capability. The shop has also added vertical turning capability with live tooling for bigger work, feeling this is a natural extension of its approach to smaller-scale jobs. Because the vertical turning machine can perform milling and drilling operations, transport of big parts throughout the shop is minimized.

The shop isn’t shy about adding advanced machining capacity, but it thoughtfully considers whether a new machine is a good fit. For instance, typical batch sizes are 20 to 50 pieces, so a twin-spindle/twin-turret lathe wouldn’t make sense because the volumes aren’t there. Similarly, the shop doesn’t focus on exceedingly complex parts, instead pursuing more conventional work and trying to complete it on one machine. Therefore, it hasn’t seen a need for a turn-mill machine with a B-axis and toolchanger. That said, Davan Manufacturing has a healthy mix of machining technologies, and would be open to integrating a different machine tool platform if it matches emerging market opportunities as well as the shop’s approach to completing parts in one setup.

Company Description

Davan Manufacturing was established in 1968 in Washington, Pennsylvania. Its original business was the manufacture of screw-machine-type parts and light sheet metal fabrication for the electronics industry. Since then, it has become adept at machining precision components in short to medium volumes for industries that require high-quality, interchangeable parts at competitive prices. Part of this strategy is leveraging horizontal machining centers with pallet-changing capabilities and turning centers with live-tooling stations that can perform milling and drilling operations.

The company has a 17,500-square-foot facility with 13 CNC machines. Its machinists, programmers, inspectors and shopfloor support personnel have an average of 24 years of job shop experience. In addition to machining capabilities, the shop offers value-added engineering and design services for its customers.

End Markets Served

- Construction

- Glass

- Mining

- Oil exploration

- Power

- Steel

- Valve

Workpiece Materials Commonly Machined

- Aluminum alloys

- Copper

- Steel alloys

- Stainless steel

- Titanium

Davan Manufacturing

500 Crile Road

Washington, Pennsylvania 15301

Phone: 724-228-0115

Fax: 724-228-0190

Related Content

Top Shops 2024 Is Now Live

The Top Shops 2024 survey for the metalworking market is now live, alongside a new homepage collecting the stories of past Honorees.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)