Tooling Helps Race Shop Take the Fast Lane

Cutting tools and expertise from Sandvik Coromant help this drag racing organization stay ahead.

Share

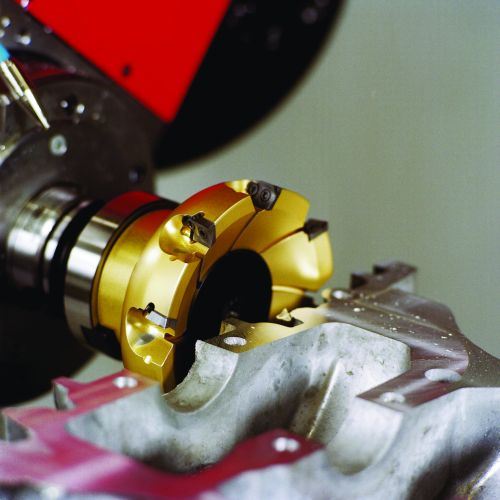

They’re called “funny cars,” but the engineering effort that goes into these dragsters’ success is no laughing matter. Behind every winning car is a team consisting not just of drivers and support staff, but also programmers and machinists tasked with producing top-quality parts on sophisticated manufacturing equipment. The recent experience of one racing organization, Don Schumacher Racing (DSR), demonstrates the value of having a supplier that can help get the most out of this equipment. Thanks to tooling and support from Sandvik Coromant (Fair Lawn, New Jersey), the company has re-vamped a troublesome cylinder head manufacturing process to improve part quality and reduce setup time, cycle time and tool costs.

overhang that caused vibration problems, and the tool often had to be sent out for resharpening. The tooling supplier recommended swapping that cutter for a 50-mm-diameter Coromill 790 router. It also brought in a Coromant Capto C5 shank to boost rigidity. Finally, the team modified the CNC program to incorporate circular interpolation techniques that reduced radial and axial cutting depth while increasing sfm and ipm. Altogether, these changes reduced the load on the spindle, reduced vibration, improved tool life and simplified tool changes, which are now a matter of changing two inserts, Mr. Keep says.

Related Content

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)