Tool Management System Eliminates Information Silos

Wagstaff Inc.'s tooling information wasn't digitally traceable or searchable. TDM Systems' Tool Life Cycle Management system reduced lost time and money for the shop.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

The Wagstaff family built a successful business designing and manufacturing systems and equipment needed to produce primary aluminum ingot and billet using direct-chill-casting methods from their 133,000-square-foot facility in Spokane, Washington. Like many companies that originate in a garage, or in this case a pump house, Wagstaff Inc. has faced various challenges as it has grown, particularly, those of “lost information.” Integrating a tool management system from TDM Systems (Schaumburg, Illinois) has helped capture the company’s tribal knowledge, saving both time and money.

Around 2004, Wagstaff began to look critically at the cost of lost information, says Jeff Smutny, manufacturing engineering manager. Product line information was stored in process documents, the CAM system and Excel spreadsheets. Tracking and leveraging the information on new jobs was difficult and not very efficient, he says. And the information wasn’t necessarily being shared amongst different users, says Russ Rasmussen, manufacturing engineering technician. For instance, product information wasn’t always adequately communicated between NC programming and the shop floor, he says, and without a central database, native information would commonly change, be cloned or mutate. There was no way to know if current, correct information was being used, which made it a challenge for workers to perform vital operations like simulating part programs.

That situation began to change in 2005 when Mr. Smutny, as a guest of Walter and Wagstaff’s local Walter distributor, visited the cutting tool company’s headquarters in Germany. He saw that Walter was using TDM System’s Tool Lifecycle Management system in its own shop, and he was impressed by its scope and capabilities.

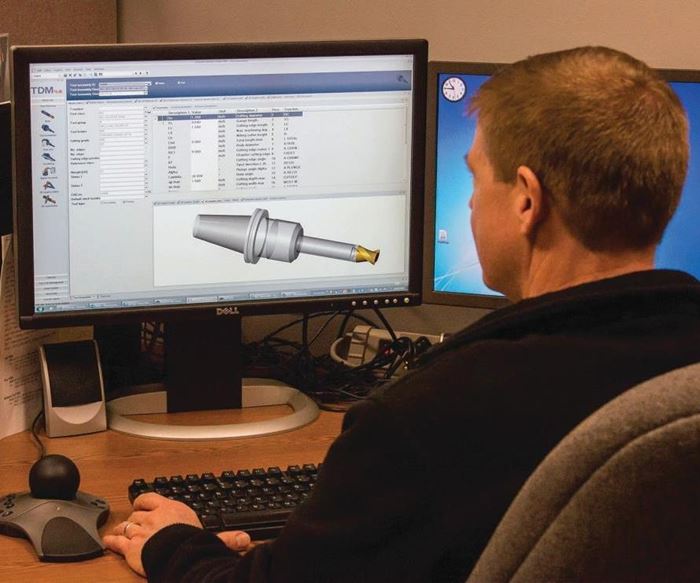

“TDM’s Tool Lifecycle Management system ensures that tool data is available where and when it is needed,” explains Dan Speidel, TDM’s director of sales. It links CAM, presetting and crib systems, and CNCs, but it can also extend upstream to systems at the planning and execution level, such as in production planning, enterprise resource planning and manufacturing execution systems. To extend so widely, a tool management system must be open and able to supply numerous import and export interfaces, he says. It must also integrate data from various sources, such as manufacturer catalogs or 3D models created in house, into a centralized database.

The Tool Lifecycle Management system collects production data and transfers it to other systems. It impacts the entire process, from tool selection to production planning to seamless transfer and use on the shop floor, Mr. Speidel says. Information from the individual process steps continuously flows back to a centralized database, creating a growing mass of data that is accessible throughout the networked system.

“Wagstaff had the typical standalone silos of information that we see in so many companies,” Mr. Speidel says. “The old process was to get a job and turn it over to manufacturing engineering to design and plan the process, then turn it over to NC programming. Once the NC program was defined, they would walk the program to the tool crib and look for the tooling. They would look in their stash, and the machine operator would often need to look through his stash.” Of course, everyone has their own preference for tooling, he adds. This was neither consistent nor efficient.

Since the shop had numerous tooling racks in a variety of locations and there was no way to digitally search for the tools, the central tool crib primarily sharpened tools and tried to maintain stock levels, Mr. Rasmussen says.

Determined to become more organized, the company decided to capitalize on its wealth of tribal knowledge. The first step was to define approximately 4,000 tool assemblies and many more components within the Tool Lifecycle Management system. Instead of relying on a CAM system’s generic tool models, this system uses actual graphics to take the guesswork and uncertainty out of tool creation, leading to efficient and repeatable accuracy, Mr. Speidel says. The system also provides basic tool information and potential applications to help Wagstaff quickly decide which tools are best-suited for each process step and which combinations are most efficient.

The tool management system stores geometry and cutting data for each tool assembly, and makes 3D tool graphics available for NC and simulation analyses. It also saves tool lists from the NC programs for future use. In addition, its recording of cutting data, machining conditions and best practices helps optimize tool use in future applications.

“Features like these are what make TDM such a benefit on repeat jobs, but it comes into play on new jobs as well,” Mr. Smutny says. “For instance, it might be a different product or application, but maybe the material is the same, so the programmers already know about the behavior of the cutting tools and tool assemblies with this material. Overall, we’ve saved a lot of time and realized increases in accuracy.”

The Tool Lifecycle Management system is designed to bring benefits to tool presetting as well, and Wagstaff eventually purchased a presetter to complement its system. TDM says it works with presetter manufacturers to facilitate two-way communication. During the measuring procedure, these systems can access the nominal data for each tool assembly stored in the TDM system and transfer the measured data back to TDM to continually fine-tune the system. This data transfer is carried out via direct numerical control (DNC) or tool chips. The tools and NC programs simultaneously get to the correct machine, together with the current preset tool data and with graphics, photos and/or captions.

Access to accurate data can reduce programming and job setup time by 25 percent. For instance, instead of needing as many as seven people in the tool crib, Wagstaff now runs the area with just three, Mr. Rasmussen says. Although the company has grown since it implemented TDM, the programming crew is staffed at roughly the same level as in 2004, Mr. Smutny adds. They now spend more time preparing revenue-producing jobs and less time searching for information.

“Now we know what we need to stock in terms of cutting tools, extensions, holders, collets, you name it. That’s definitely streamlined the purchasing function, in addition to reduction of inventory,” Mr. Rasmussen says. Full knowledge of Wagstaff’s tools and their capabilities has enabled the company to reduce its purchases in some areas.

Although buy-in to the new system wasn’t automatic, it is well-accepted by Wagstaff’s staff today, Mr. Rasmussen says. “People don’t like to adopt new things, so there’s always some degree of hesitancy. However, one of our programmers recently mentioned to me that he didn’t know how he did his job without TDM. It’s become a vital part of our successful operation.”

Related Content

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)