Three Technology Takeaways from FANUC Tour

New CNC, automation and Internet of Things technologies stood out during a recent event at FANUC’s manufacturing campus in Japan.

Share

Demonstrations at the event showed applications for the FANUC Intelligent Edge Link and Drive (FIELD) system, an open IoT platform that connects CNC machine tools and robots as well as peripheral devices and sensors.

I recently got the chance to visit FANUC’s manufacturing campus (on 1.2 million square meters of land) located near Mount Fuji in Oshino-mura, Yamanashi, Japan. This was my third visit there, where the company offered new technology demonstrations and tours of its servo-motor, milling, repair and robot factories to me and various U.S. manufacturing representatives. It’s pretty cool to see production cells in which robots build robots. It also remains impressive to me that FANUC produces 5,000 robots per month and 125,000 servo motors per month, and repairs customer circuit boards, servo motors, etc. that are sometimes more than 30 years old.

As I walked through the company’s new-product demonstration area, the following three technologies stood out to me, and their descriptions will give you a sense as to what the company will be presenting at IMTS:

• FIELD IoT technology—A collaboration with FANUC, Cisco, Rockwell Automation and Preferred Networks (a provider of artificial intelligence solutions) has resulted in the development of the FANUC Intelligent Edge Link and Drive (FIELD) system, a platform that connects CNC machine tools and robots as well as peripheral devices and sensors to deliver analytics that can optimize manufacturing production. Because this is an open platform, application developers, sensor and peripheral device makers, system integrators and others can build and integrate custom solutions that improve equipment efficiency, manufacturing output and quality.

The FIELD system extends the capabilities of the existing FANUC Zero Downtime (ZDT) connected-robots project that uses Cisco’s cloud-data-collection software. ZDT is said to proactively detect and then inform users of potential equipment or process problems before unexpected downtime occurs, enabling the maintenance issue to be addressed in a planned outage timeframe. FIELD takes this further by combining both artificial intelligence and edge-computing technologies to provide distributed learning. Data generated by robots and machines are processed in real time at the edge of the network so those devices can intelligently coordinate and collaborate in a flexible manner for applications such as bin-picking robots, anomaly detection, and failure prediction (the company refers to this as “deep learning”).

FANUC’s first collaborative robot offered 35-kg payload capacity. It has introduced more compact models with 4- and 7-kg capacity.

• Expanded collaborative robot line—FANUC took an interesting approach when it entered the collaborative robot market a few years ago (collaborative robots use sensing technology to enable them to safely work together with humans in a shared space). While some manufacturers started with light-payload models and are developing units with increased payloads, FANUC’s first model, the CR-35iA, was designed to be a high-payload model offering 35-kg capacity. It also has hand-guided, direct-teaching capability available. The company has since introduced three additional, more compact models. One offers 4-kg payload and 550-mm reach, and two others offer 7-kg capacity and 717- and 911-mm reach, respectively. All of these feature the company’s now-signature “collaborative green” soft finish to further reduce impact force.

Mike Cicco, who recently became President and COO of FANUC America (with Rick Schneider remaining as Chairman and CEO), notes that FANUC was also involved in collaborating to create the recently published ISO/TS 15066 technical specification, which serves as a supplemental document to the existing ISO 10218 industrial robot standards to facilitate collaborative robot integration. What’s key is that it offers guidance for robot integrators and manufacturing personnel to conduct more sophisticated preliminary risk assessments of both the collaborative robot system and the environment it will share with humans. Although Mr. Cicco admits ISO/TS 15066 is a bit complicated to follow, and that refinement of the risk-assessment guidance it provides is expected, it is a good first step to facilitate the integration of this automation technology.

He also says the company’s robotic automation business has seen growth in automotive and electronics industries. However, Mr. Cicco notes that there remains significant opportunity for robotic automation in machine shops, despite the fact that this is perhaps one of oldest applications for robotic technology. (Similarly, during my visit to FANUC in 2014, Mr. Schneider noted these reasons why robots will become more commonplace in U.S. manufacturing facilities.)

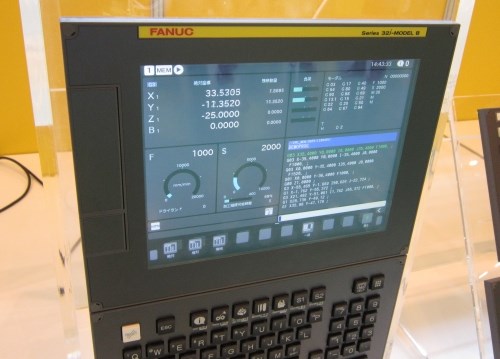

This model of the new iHMI series has a 19-inch touchscreen display and looks different than other FANUC controls you’ve likely encountered.

• New CNC look/interface—FANUC’s iHMI series of CNCs with flat panel design (including the Series 30i Model B shown above offering a 19-inch touchscreen display) represents a departure from the FANUC control you’re used to using. It’s also likely to offer a comfort level to the next generation of shopfloor employees who have grown accustomed to working with tablets and smart phones. This new series also complements FANUC’s FIELD technology, offering new maintenance and data logger functions required for IoT and smart-factory applications.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.png;maxWidth=300;quality=90)