The Right Touch of Indexing Capability

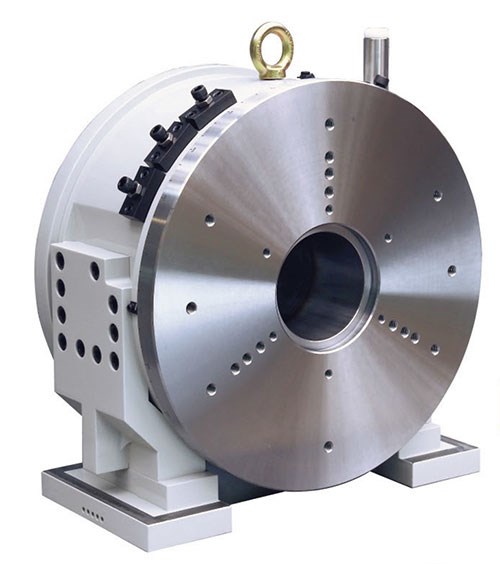

Mechanical rotary indexers like these can be installed on a machine quickly and take up less table real estate of motorized indexers.

Share

Indexers are valuable workholding devices that bring fourth- or fifth-axis part rotation capability to a conventional three-axis machine tool. This enables the machine to access more sides of a clamped part to reduce the number of setups and ensure feature-to-feature accuracy.

Common versions use a motor to rotate the table and require power cables and a digital interface to the machine’s CNC. However, the Touchdex line of indexers from Japanese workholding device manufacturer Kawata is a fully mechanical alternative that can be installed on a machine quickly and take up less table real estate of motorized indexers.

In fact, the company says its lightweight indexers require just half the table area than conventional motorized indexers, which can also make it possible to install multiple indexers on one machine table. Touchdex indexers, which are offered in a number of configurations, are available in the United States through Tecnara Tooling Systems in Santa Fe Springs, Calif.

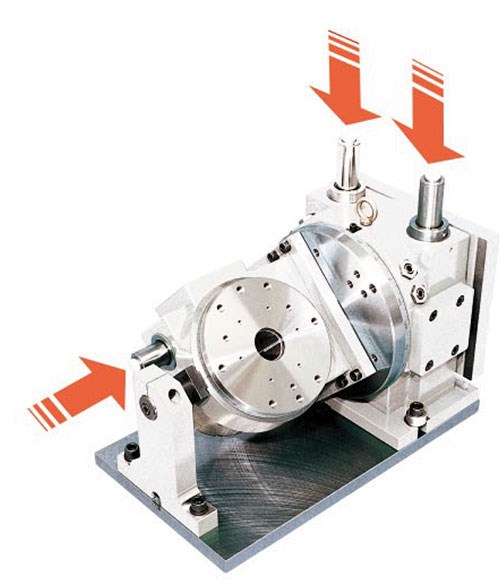

For these mechanical devices, the machine tool performs the indexing. It does so by feeding an installed cutter at least 10 mm in diameter down to drive the indexer’s linear push bar that rotates the table. (Indexing positioning accuracy is less than 30 seconds cumulative and repeatability is ±3 seconds.) Once the zero-backlash indexer rotates a part to the proper orientation, a locking pin maintains the table position by providing a clamping force that is two to three times greater than units that use a typical friction brake, the company says. This is said to enable heavier milling, drilling and tapping operations.

To set up a Touchdex indexer installed on a machine, an operator jogs a non-rotating cutter over the indexer’s push bar and saves that Z-axis height to memory. With the pulse of the machine’s handle movement set to 0.01 mm, the operator feeds the cutter down, plunging the push bar until the indexing table rotates to the proper angle as indicated on the indexer’s angular position scale. Users can then create a program based on those two Z-axis positions.

The base Touchdex model unit has one push bar and provides clockwise indexing rotation only. A full push bar stroke for these models indexes the table 45 degrees, and the indexing unit is clamped in place when the push bar returns to full extension. The largest of these models offers a table diameter of 450 mm, a 120-mm through-hole and a center height of 250 mm.

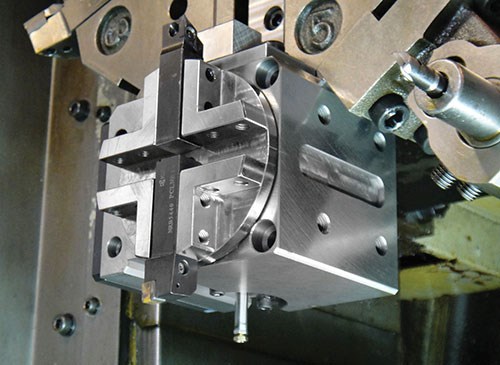

However, a variety of other models are available, including units that offer two push bars to enable clockwise and counterclockwise rotation, units that rotate their table 90 degrees with each full push bar stroke, and units that enable indexing in 1-degree increments for complex workpieces. There are also indexing trunnion table designs and combination units that enable five-axis positioning or 3 + 2 machining (full five-axis contouring is not possible). The Touchdex concept has also been applied to lathes to provide these machines with extra cutters, as shown in the bottom photo.

Learn more about Tecnara Tooling Systems.

Related Content

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.