The Need to Know Is Basic

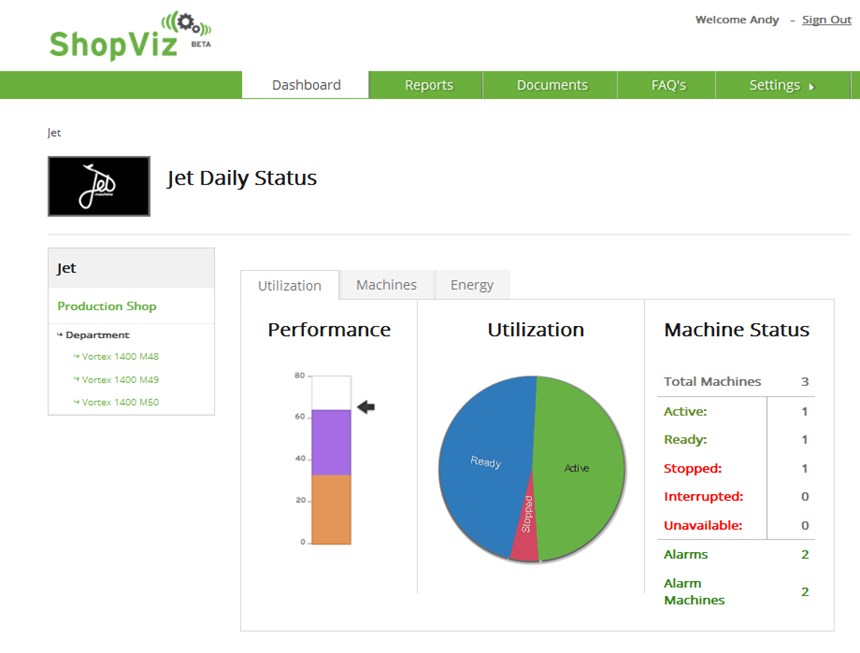

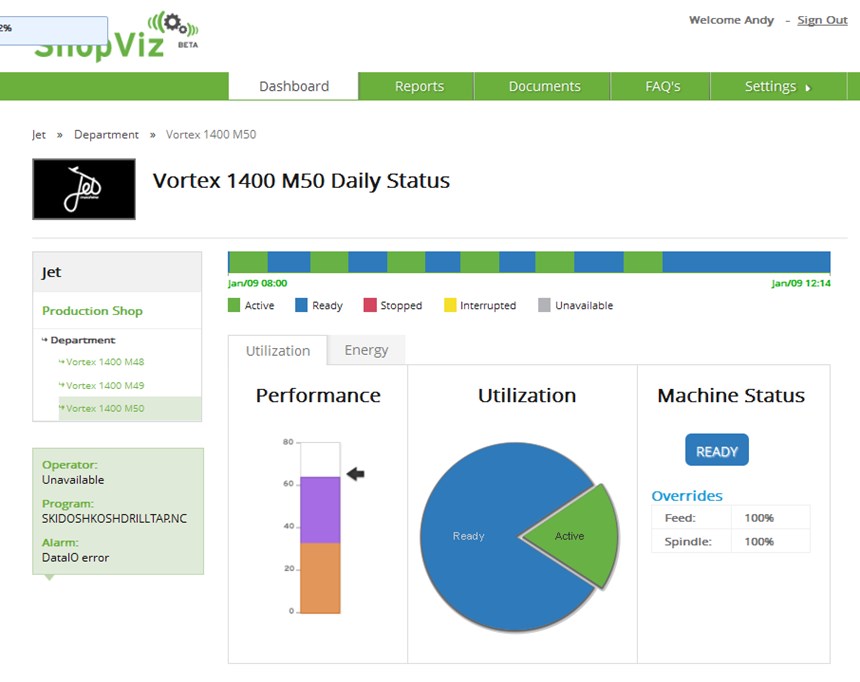

An MTConnect-enabled monitoring system gives this shop a clear and simple picture of machine tool usage.

Share

Are our machines running? How long have they been running? Are they getting parts done on time? Do the operators need help?

These are some of the questions that Adam Wulfeck wants answered. As vice president of sales at Jet Machine and Manufacturing in Cincinnati, Ohio, Mr. Wulfeck is responsible for keeping the shop floor fully loaded with profitable work. These questions are important because the answers help resolve other critical concerns about running a successful contract machining business. The concerns include: Are our machining resources being utilized effectively? Are they delivering the expected return? Are actual run times close to the estimates?

A new MTConnect-based machine monitoring system is helping Jet Machine get reliable answers to these questions. Although currently implemented as a pilot program on three of the shop’s most important five-axis machine tools, the system gives Mr. Wulfeck and other managers a timely and accurate picture of machine utilization and performance. This makes it easier to make good decisions about both short-term issues, such as maintenance priorities, and long-term issues, such as new capital acquisitions. Plans call for connecting all of the shop’s CNC machines to this monitoring system.

In the meantime, machine monitoring is proving to be an important element in the critical transitions underway at Jet Machine. Once heavily involved in production work for a defense contractor, the company is returning to its roots as a diversified job shop. It is also undergoing a generational change in leadership as grandsons of the founder take on more responsibility in running the business. Getting essential information about machine activity on the shop floor will make these transitions smoother and provide a clearer direction.

A Shop in Transition

Concerns about machine performance and utilization became especially nagging to Mr. Wulfeck and other family members who own and manage Jet Machine at the beginning of 2011. At the time, the company’s long-running defense work was beginning to wind down, and it was bidding on several new contracts for the energy sector and other industries. Moving away from production work, which had occupied much of the shop’s machining capacity for several years, meant that there would be less certainty about how to use machining resources most effectively. For example, the company had invested in additional five-axis capability for the defense work, so it was important to sustain the earning power of these machines.

At the same time, the company was undergoing a shift in management from the second generation of owners/managers to the third. Jet Machine was founded in 1970 by James Wulfeck, Sr. as a machine shop that specialized in boring mills. As the company grew, it expanded into general machining, relocated its facilities and concentrated on CNC operations. James’ sons Rick and Ken eventually took over and, in turn, their sons became involved in the business. In time, Adam, his brother Brad (the plant manager) and their cousins started taking on more and more responsibility as their fathers moved toward retirement. “If ever there was a time when we needed a clear picture of what was happening on the shop floor, it was during this period,” Mr. Wulfeck recalls. “We wanted to be sure the new direction we were taking was the best one.”

With 85 or so employees and 60-plus machine tools (mostly CNC) in a building with 85,000 square feet of shop space, the continued success of the company could be jeopardized by false moves in the highly competitive job shop market. For example, one particular contract in the energy sector looked right for the company, but it would tie up most of the shop’s five-axis machines—the machines most in demand, judging from incoming requests for quotes. The younger Wulfecks didn’t want to base decisions about new jobs on guesswork. “We wanted facts about shop performance and machine usage to be our guides,” Mr. Wulfeck says.

Around this time, however, a very neighborly thing happened. Jet Machine was approached by TechSolve, a manufacturing technology research and development firm located about a half-mile away in the same business park. This firm was looking for a machine shop to be its test site for a new machine monitoring system under development. This system was designed for (and inspired by) MTConnect, the communication protocol introduced as a standard for the manufacturing industry in 2008.

Ron Pieper, a project manager at TechSolve and program director for the firm’s MTConnect Solutions initiative, was familiar with Jet Machine from earlier posts in his career. He knew the layout of the shop and its management team. This shop seemed to be the perfect candidate as a test site. “Jet is focused on advanced machining, has an open and receptive management style and faces many of the challenges that job shops across the country are facing,” Mr. Pieper says.

In a nutshell, the machine monitoring system (now called ShopViz) is designed to provide a readily deployable method for monitoring machine status and job status at a glance. This system is based on the belief that shop managers need only essential information to make good, quick decisions. Too much data obscures the issues. “The information has to be accurate, current and exactly what a manager needs to know. The way it is reported has to be clear, simple and easy to interpret,” Mr. Pieper says.

He adds that MTConnect was a key element in this scenario. Literally, this communications standard helps unlock the machine tool’s CNC as a source of data for external applications. MTConnect also opens the channels for the data to flow to the “cloud,” across the Internet and to any Web-enabled electronic device.

The MTConnect Connection

Mr. Pieper became aware of MTConnect during a prior stint with a manufacturer of CNC systems that participated in the introductory demonstration of the communications standard at IMTS 2008. One of the things that impressed him about MTConnect was its simplicity. “All the standard does is specify a set of terms with defined meanings in a neutral, non-proprietary format that can be shared on digital networks,” Mr. Pieper says.

MTConnect serves as a communications protocol, which simply means it defines the rules that manufacturing equipment can follow to share data with software applications. It uses Hyper Text Transfer Protocol (HTTP) and Extensible Markup Language (XML), which are building blocks of Web-based communication.

Mr. Pieper saw that the developers of the initial version of MTConnect had a sound grasp of the characteristics needed to maximize its usefulness to equipment suppliers and end users. The standard is designed to be “lightweight”—that is, it consumes relatively few data processing resources. It is extensible. New sets of defined terms can be continuously added to cover a range of machine tools, accessories and other manufacturing equipment. Because it uses HTTP and XML, it is Internet-ready.

It’s All About the Apps

By the time Mr. Pieper and Amit Deshpande, the machining systems engineer working with him on the machine monitoring system, approached Jet Machine about serving as a test site, they had clarified their vision for the functionality of the application. Their involvement with the technical groups under the MTConnect Institute’s umbrella convinced them that the success of MTConnect hinged on its acceptance by both suppliers and end users. “We saw that this acceptance would largely depend on third-party applications that create value,” Mr. Pieper says.

As Mr. Deshpande explains, MTConnect doesn’t really do anything. “It simply makes it possible for data to be extracted easily from all kinds of digital manufacturing equipment. Then the data can be used by external applications that enhance shopfloor operations,” he says. These software programs do the work that makes the data useful.

However, most MTConnect implementations also require additional software utilities, such as “agents” and “adapters.” An adapter is simply the conduit by which the MTConnect agent interfaces with manufacturing equipment to retrieve data. The agent is a program that acts as a universal translator for machine-specific data. The adapter extracts the CNC’s internally generated data and makes it available to an MTConnect agent. The agent then takes that data from the adapter, converts it into the terms and format defined by the MTConnect standard, and makes the translation available on the network in the same way a website makes data available. This formatting enables the data to be collected and transmitted by the corresponding MTConnect agent for use in an application.

“One of our concerns was the urgency of getting MTConnect implemented widely by machine tool users,” Mr. Pieper adds. “Field-proven benefits of MTConnect applications are the most compelling way to promote the standard and ensure its continued development and expansion.” By using standard Internet protocols, MTConnect-enabled applications can be implemented modularly because having a “common language” facilitates integration. “In other words, MTConnect applications can feed each other,” he says.

Mr. Deshpande says TechSolve’s entry in the growing base of MTConnect applications was designed for small- and medium-sized job shops as an entry-level software product upon which other applications can be added. “We saw some very capable and sophisticated applications being rolled out for MTConnect-compliant equipment, and that speaks to the robustness and usability of the standard. However, one of the most powerful things about it is its potential for simple machine monitoring—creating a clear picture of shop activity. Shop-Talk is modeled after this premise,” he says.

Plotting a New Course

Jet Machine’s pilot program with the machine- monitoring system involves three Mazak Vortex 1400/160II VMCs with five-axis machining capability. These 50-taper machines have X-, Y- and Z-axis travels of 4,200, 1,400 and 610 mm (165, 55 and 24 inches). The company acquired these machines in late 2007 and early 2008 because a design change issued by the defense contractor required five-axis machining to produce a more complex part geometry. As orders from this customer fell off in early 2011, Jet Machine was eager to redeploy these productive machining assets. Because the size and capability of these machines are rare, many opportunities were soon available.

That was one reason these machines were chosen for the pilot program. Information about usage and performance would verify that they completed the new jobs on time, delivered the expected profit margins and were fully scheduled. For example, when the pilot program started in April 2011, Jet Machine was looking closely at a contract to machine bathtub-sized steel castings for a slurry manifold used in “fracking,” the process of hydraulically fracturing dense deposits of underground shale to release the natural gas or oil trapped within. These exceptionally large, heavy workpieces fit the Vortex machines perfectly, but to be competitive and profitable, they would have to be machined efficiently, with little room for unplanned downtime, cycle time overruns or excessive tool consumption. Reliable machine monitoring would ensure that these problems could be avoided and that this long-running contract would yield its expected return.

To connect each machine to the new monitoring system, the shop dropped a network cable from the ceiling to an Ethernet port at the side of the CNC. Because these machines were delivered before Mazak had made MTConnect compliance a standard feature, the builder installed an adapter to output real-time data representing alarms, alerts, cycle starts and stops, feed overrides or other operator interventions, and more.

Data from the adapters is collected by the MTConnect agent, which runs on a network server in the engineering office. From there, it goes to the Shop-Talk application software to be compiled and presented for viewing. This application software resides in the cloud (see Editor's Picks: "Getting Ahead in the Cloud").

To access the machine-monitoring system, Jet staff can enter the appropriate Web address (URL) on any device with a Web browser, such as a PC, iPad, SmartPhone and so on. Passwords and encryption protect the security and integrity of the data. When the application opens, the main Shop-Talk screen displays a color-coded box for each monitored machine showing its current status. At a glance, the user can see which machines are running, in setup or experiencing downtime. More detailed views are available by selecting various tabs.

For example, one tab opens a timeline showing machine usage and activity over a selected time interval. Color codes indicate the changes in machine status during this period. Individual events, such as alarms or alerts, appear as they occurred and can be accessed for analysis of details and to prepare a response. According to Mr. Pieper, all of the displays are designed to be “highly visible.” “Managers can take a quick look and instantly see how things are going at each machine,” he says.

The data also makes trends apparent. For example, data from the Vortex machines helped establish a baseline for machine utilization and performance. This quickly proved its value. As it turned out, Jet Machine began processing the large oilfield manifolds on these machines and is ramping up production. Machine monitoring has given the company confidence in the decisions made about this work, and moving ahead, it is providing assurance that the shop can stay on track with on-time deliveries. “The data also helps us justify overtime when required to keep up, and in the long term, it will help us determine if additional machining capacity is truly needed,” Mr. Wulfeck says.

Looking Ahead

By September 2011, Jet Machine’s experience with the pilot implementation of the machine monitoring system had validated its underlying conceptual basis and significantly aided the developers in refining its functionality and effectiveness. The initial release of the ShopViz application software is planned to coincide with the MC2 Conference in Cincinnati in November 2011 (see article in grey box below: "Connecting with MTConnect at the MC2 Conference"). Mr. Pieper predicts that as MTConnect-enabled applications proliferate, equipment manufacturers and end users will have many suitable choices for integrating and automating shop processes through better data communication between shopfloor machines and systems. “Our entry is focused on job shops looking for a product that makes entry-level machine monitoring attractive, but manufacturing companies of all sizes will have choices for improving operations with MTConnect-based applications,” he says.

Looking ahead, Jet Machine has made one of its goals the integration of the machine monitoring system with its shop scheduling system. The shop has been using commercial ERP software modules for shop accounting and costing, but it handled job scheduling on a home-grown Excel spreadsheet. This method is being replaced by the shop-scheduling module recently added to the ERP system. TechSolve is working with the shop to develop an interface that will enable job status data to flow into the new scheduling module. In addition to lower data-collection costs and less-intrusive data entry duties for machine operators, an important anticipated benefit will be spotting opportunities to fill available time on the five-axis machines that otherwise would be lost to scheduling oversights. Tighter, more timely scheduling will also help reduce costly setup delays.

Of course, adding other machines to the monitoring system will proceed as time and resources allow. Likely candidates will be several Mazak machines installed this year, including a Variaxis 730-II five-axis VMC and a QTN-450MY multi-tasking lathe with Y-axis milling capability. Like all machines from this builder, MTConnect capability is supplied from the factory, so adding these machines will be a simple process.

In the meantime, Mr. Wulfeck notes that a working machine monitoring system is being gradually absorbed into the shop’s management routines. Simply keeping tabs on machine usage and job status makes a big difference in the shop’s ability to be efficient and thrifty. This represents a subtle but important change in the shop’s culture. However, everyone at Jet Machine would agree that having access to a clear, objective view of machine activity is a much-wished-for development. For example, Rick and Ken Wulfeck (Adam’s father and uncle, respectively) use the system to stay actively involved as advisors.

Perhaps this shop’s experience with machine monitoring is best summarized by saying that the need to know is basic, and it’s the basics that a shop needs to know.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg) Amit Deshpande (left) and Ron Pieper discuss the advantages of cloud computing for machine monitoring in the small- and medium-sized job shop.

Amit Deshpande (left) and Ron Pieper discuss the advantages of cloud computing for machine monitoring in the small- and medium-sized job shop.

.jpg;maxWidth=300;quality=90)