Published

The Material Difference

In some cases, thick-walled, seamless tubes make more sense than solid barstock for certain stainless cylindrical parts.

Share

For many turning applications, conventional thinking suggests work should begin with solid barstock. However, Sandvik Materials Technology thinks this might not be the most efficient or cost-effective way to produce a cylindrical part from stainless steel, especially if the completed part has a large bore. Instead, the company says its Hollow Bar line of thick-walled, seamless stainless tubes might make more sense for these applications because it can reduce tooling costs and lower overall part costs while eliminating some machining operations.

Sandvik’s Hollow Bar material is available in several of the company’s Sanmac austenitic and duplex stainless steel grades (the latter of which is commonly used for oil and gas components). These grades are said to offer improved machinability compared to others. This is possible through better control of the type and amount of non-metallic inclusions while maintaining the corrosion-resistant properties necessary to resist cracking in chloride-laden environments (common with oil and gas applications). Plus, the company says the material offers batch-to-batch uniformity. The various Hollow Bar sizes range in ODs from 32 to 275 mm and are available with a variety of IDs.

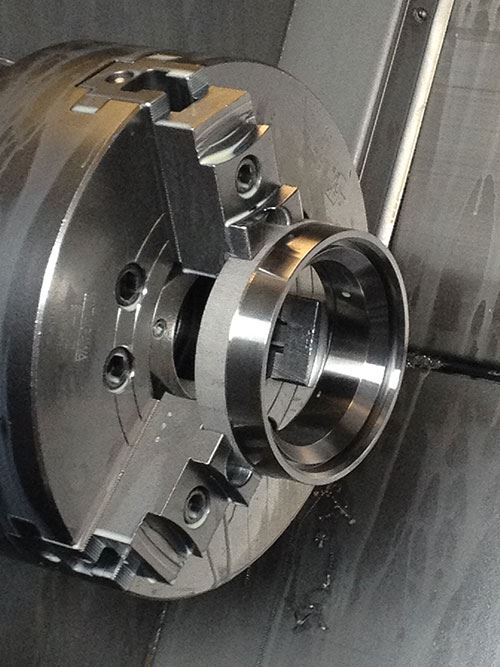

Consider the part below, a duplex stainless ball valve seat for an oilfield valve assembly. Added Value for Valves (AVV), an Italian designer and manufacturer of complex valve components, recently used this part in machining tests to evaluate the potential time and cost savings using Sandvik’s Sanmac 2205-grade Hollow Bar versus a similar EN 1.4462-grade solid bar.

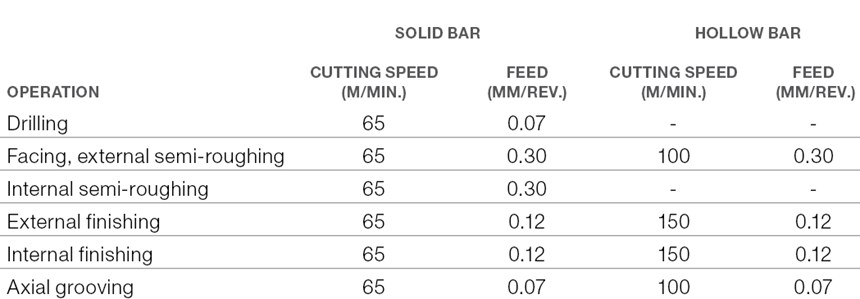

For the solid bar, op-10 work begins with a drilling operation to create the bore followed by facing, external semi-roughing, internal semi-roughing, external finishing, internal finishing and grooving. However, the drilling and internal semi-roughing operations are not required when using the Hollow Bar material, which, in this case, had a 140-mm OD and 100-mm bore. (See the table to the left for a list of the operations and cutting data used for both material types.) For both batches of material, identical op-20 semi-roughing and finishing operations were performed on the back side of each part.

Eliminating the op-10 drilling and internal semi-roughing operations yielded considerable overall time savings. Compared to solid stock, that amounts to a time savings of 4 hours per batch of 20 components for an overall productivity increase of 224 percent versus solid stock. Processing time for one part machined was 18.86 minutes for the solid bar versus 5.82 minutes for the Hollow Bar, and, after considering all material and processing costs, the price to produce each component was $64.93 and $43.26, respectively. Therefore, the total cost savings for a batch of 20 components using Hollow Bar was $432.76.

During the tests, AVV also noted other benefits with using the Hollow Bar material. For example, it wasn’t necessary for an operator to remove the tangled chips that commonly plague drilling operations. Also, higher cutting speeds could be used while maintaining tool life, and fewer tools were needed for the job. In addition, although overall insert wear was essentially the same for both types of stock, more pronounced wear was found on the rake face of the insert used for the solid bar (likely due to crater wear). This wear pattern was not present on the insert used for machining the Hollow Bar.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

Workforce Development

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More