The Fluid Transition

A watershed moment in spindle evolution? For the latest generation of high speed spindles used in milling, spindle makers look beyond traditional bearings.

Share

Bearings for machining center spindles have seen a variety of incremental improvements. The introduction of "hybrid" ball bearings using ceramic balls in a steel race extended performance beyond that of bearings with all-steel components. Lubrication systems further extended performance by getting better at delivering lubricant between the ball and the race where it could do the most good.

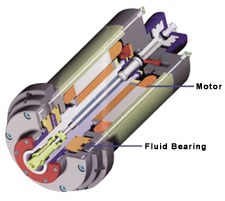

But incremental improvement is only one way for a technology to advance. Another way is through fundamental change. And today, major spindle suppliers seem to be indicating that a time of fundamental change has come for spindle bearings used in milling. Multiple spindle makers are preparing to come to market with spindles that replace mechanical ball bearings with hydrostatic bearings—that is, fluid bearings—that are free of contact between moving surfaces. The fluid used in these bearings is water.

A fluid bearing is nothing new, nor is the idea of using water as the bearing medium. What is new, say spindle suppliers, is a heightened demand to apply this technology in milling. Spindle motors available today can deliver more power, and cutting tools are now available that can put the increased power to use. The limiting factor is the bearing. Hybrid ball bearings used in the high-end milling spindles in service today appear to represent the practical limit of how much speed and power a mechanical bearing can put to use and still maintain a long service life. But fluid bearings, with their higher load capacity, overcome this performance limit.

There are other reasons why this type of bearing is suited to high speed and high power machining. The fluid delivers smooth motion, damps vibration and ensures low runout. All of these factors may prolong the life of the more costly, more shock-sensitive cutting tools that aggressive milling processes are likely to employ.

Companies at work on high speed spindles with water bearings include Fischer USA (New Brighton, Minnesota) and Ibag North America (North Haven, Connecticut). Both companies are still testing their products, so details are subject to change—including details cited in this article.

One application poised to benefit from this performance can be found in the aerospace industry, where high spindle speed is combined with heavy depths of cut to hog out aluminum aircraft components at high metal removal rates.

But the general outlook is clear. Both companies see fluid bearings using water as the next enabling technology that will make it practical for them to offer higher levels of performance to milling applications.

Another high speed, high power application that may be growing in significance is hard steel mold and die milling. Here, the spindle's potential to extend the life of expensive cutting tools is particularly valuable.

In both applications, some shops today already have the knowledge and process components they need to take advantage of even higher spindle speed and power—they just need the spindle to take them there. When more capable spindles do arrive, the transition in shops like these can be fluid indeed.

Why Fluid Bearings

A fluid bearing is a non-contact bearing. There is no mechanical contact between moving surfaces. In a ball bearing, there is (at best) just lubrication between the ball and the race. But in a fluid bearing, the fluid completely isolates the spinning component from the stationary one.

There are other ways to realize a non-contact bearing. For example, the fluid doesn't have to be a liquid. It could be air. Also, electromagnetism can create an effective non-contact bearing. But both of these bearing types have drawbacks. An air bearing lacks stiffness, while a magnetic bearing results in an expensive spindle design. Using a fluid such as oil or water as the bearing medium produces a spindle that can be both cost-effective and effective for heavy cutting.

Most of a fluid bearing's advantages over a ball bearing can be attributed to the lack of mechanical contact. This trait explains why the fluid bearing can bear a heavier load, for example. Forces may be higher, but the force is spread evenly throughout the fluid instead of being focused onto the narrow contact areas of moving parts that are susceptible to stress and strain.

The lack of contact also explains the fluid spindle's low runout. Accuracy in a ball bearing is affected by the stack-up of mechanical tolerances. In a fluid bearing, evenly distributed pressure tends to hold the shaft on centerline.

But perhaps the most striking difference between a mechanical bearing and a fluid bearing relates to maintenance. The fluid bearing might not need maintenance. With no mechanical contact to wear out moving parts, the fluid bearing stands to deliver considerably longer life.

Why Water Bearings

These are important advantages. However, a distinct drawback to using a liquid as the bearing medium is the inefficiency that results from the liquid's viscosity. This viscosity is liquid friction. The motor has to work harder just to overcome this resistance in the bearing.

Minimizing viscosity losses accounts for why water is used. Though hydrostatic bearings run at lower speeds can use a more viscous fluid such as oil, higher rpm requires an easier-flowing liquid.

However, the switch to water is no simple substitution. Oil is an attractive choice because it's essentially non-reactive and non-conductive. Water isn't. To use water as the bearing medium, the spindle maker takes a variety of additional steps during manufacturing that may include coating internal components, sealing the motor and using deionized water.

Gyroscopic Bearing

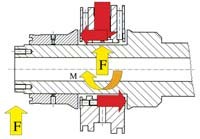

To reduce viscosity losses further, spindle maker Ibag says it designed its water bearing spindle to use only one bearing. A self-stabilizing gyroscopic effect lets this bearing act alone to support the spindle shaft.

A magnetic bearing is capable of a similar self-stabilizing effect. Comparison with a magnetic bearing is natural here because the company also offers a magnetic spindle. However, in a fluid bearing, the gyroscopic effect is less complex, says North American company president Bill Popoli. Stabilizing a magnetic bearing requires sensors to adjust the intensity of the magnetic field. The fluid bearing achieves the same effect through fluid mechanics alone.

The resulting freedom to use just one bearing brings viscosity losses down to the range of 10 to 15 percent, where some hydrostatic spindle designs have losses of 40 to 50 percent, Mr. Popoli says.

Ibag's fluid bearing spindle will initially be available in two different continuous power and top speed combinations: 32 kW/32,000 rpm and 40 kW/40,000 rpm. The cost will fall between that of mechanical and magnetic bearing spindles. A magnetic spindle represents a 50 to 100 percent premium over a roughly comparable ball bearing spindle, he says. By comparison, the premium for the hydrostatic spindle will be about 25 to 30 percent.

In the company's further development of this technology, one fluid bearing advantage being given careful attention is the bearing's applicability across a wide range of speeds, Mr. Popoli says. High fluid pressure can make a fluid bearing very stiff, but using the same high pressure at high speeds would make viscosity losses excessive.

"But what about a spindle that varies fluid pressure in proportion to the speed?" he says. "We are evaluating designs that do exactly that—increase pressure as speed goes down." If feasible, the result would be a spindle that is just as capable in slow, heavy cutting as it is in high speed machining.

Power Density

The design efforts of another spindle maker, Fischer, have resulted in a spindle that concentrates high power in a small volume. This company's soon-to-be-released "Hydro F" water bearing spindle delivers 80 kW continuous power and 40,000 rpm. By contrast, the company's high-end mechanical bearing spindle delivers 40 kW/40,000 rpm. At double the power, the hydrostatic spindle fits in the same size housing as its mechanical predecessor.

Testing of this spindle has involved high-metal-removal-rate aerospace milling. Test applications include high speed machining of aluminum at high depth and chip load using a 3/4-inch tool.

However, Fischer USA president Martin Rüegsegger says high speed and high power machining is only an introductory step. His company foresees fluid bearings applied not just in this application, but in every application where the company's spindles are used.

"We're not focused on any application in particular," he says. "We are evaluating fluid bearings as a potential replacement for mechanical bearings throughout our product line."

If fluid bearing spindles gain acceptance, he says, there is every reason to believe the price of manufacturing them will come down. They may become less expensive than the mechanical bearing variety. Certainly the after-market costs will be considerably less.

"With our fluid bearing spindle design, we eliminate one-third to one-half of the moving parts," he says. This simplifies service. For example, part of the difficulty of servicing a mechanical bearing is the lubrication system that forms a critical and complex connection between stationary and rotating parts. In a fluid bearing design, this connection goes away, making the rotating parts far more accessible.

Bearing Ahead

And making this bearing technology "accessible"—in more ways than one—is a primary concern for Fischer. The company is looking for partner companies that can help it encourage fluid bearings' widespread use. This is in keeping with the goal of making the fluid bearing a more universal choice.

Mr. Rüegsegger notes that the ball bearing is not an exclusive technology—it's a fundamental platform on which most metalworking spindles are built.

Similarly, the company recognizes that fluid bearings for milling spindles are less likely to gain wide acceptance if any design is limited to a single supplier. That's why continuing to test and refine the spindle is only one of the priorities. The other way the company plans to advance this technology is by building relationships with other metalworking suppliers.

Related Content

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)