The Evolution of the Retention Pin

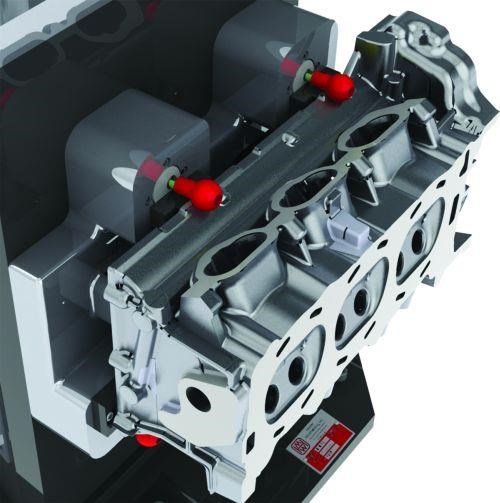

A new retention pin design enables the spring-loaded workholding devices to do more than simply ease part loading. They can clamp parts, too.

Share

Over the years, spring-loaded retention pin designs have evolved. Traditionally, they have helped users locate a part on a fixture and hold it in place before actuating swing or link clamps that secure the part for machining. However, this new version from Master Workholding includes a hydraulic circuit enabling the devices to function as clamps, too.

Related Content

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.