The Auto Industry & Gear Making

How do you create products that are cost competitive and of the highest quality? Here are three approaches, one about a car manufacturer putting more emphasis on its capacity, one about a machine producer increasing efficiency through flowing parts, and one about a car maker assuring quality in production.

Share

ECi Software Solutions, Inc.

Featured Content

View More

The importance of gears made right in the auto industry cannot be overstated. In fact, there is probably no more critical element to the performance of a car or truck than its transmission, be it automatic or manual. But because it is the mass-production auto industry, in which cars and trucks are rolling off the line at 60 or more jobs per hour, volumes are key and cost is king. So how do you create products that are cost competitive and of the highest quality? Here are three approaches, one about a car manufacturer putting more emphasis on its capacity, one about how a machine producer is increasing efficiency through flowing parts, and one about how a car maker is assuring quality in production.

Chrysler Makes Gears in Kokomo—Plenty of Them

People who develop and manufacture gears for automotive applications are a special breed, dedicated to what is seemingly a blend of art, science and engineering.

Kokomo, Indiana, may not be the world’s capital of gear production, but that city, located about 60 miles due north of Indianapolis, more than makes its share of gears. Kokomo is the home of the Chrysler Kokomo Transmission Plant, the Chrysler Indiana Transmission Plant I and the Indiana Transmission Plant II.

KTP is a 3.1-million-square-foot plant that produces a variety of transmissions, including those for the Chrysler Town & Country minivan, the Dodge Avenger, Chrysler 200, Dodge Journey, Jeep Grand Cherokee, Chrysler 300, and Dodge Charger.

ITP I is a 1.2-million-square-foot plant that manufactures rear-drive transmissions for the Grand Cherokee, Dodge Durango and Ram pickups. ITP II is the newest and the smallest of the plants; it opened in 2003 (ITP I: 1998; KTP: 1956), and at 600,000 square feet,it produces five-speeds for the 300, Grand Cherokee, Durango, Challenger and Charger.

Chrysler is committed to these transmission facilities. Just listen to Sergio Marchionne chair-man and CEO of Chrysler, speaking in Kokomo on Feb. 28, 2013: “Today, I am delighted to formally announce that we will expand our powertrain manufacturing presence in this region to build the most fuel-efficient transmission in the industry.”

He’s talking about a nine-speed.

“As you know, this is the sole region where we manufacture transmissions, and—including all of the nearby facilities—it will be the largest transmission installation in the world.

“One of the reasons for today’s event is to celebrate the start of production of an eight-speed automatic transmission here at Kokomo Transmission. And to expand operations, I am pleased to announce that we are investing $212 million for equipment and tooling here at Kokomo Transmission and at the nearby Kokomo Casting Plant and Indiana Transmission Plant I, which will create more than 400 additional jobs. In addition to our investment in existing facilities, we are also spending

$162 million to establish a new production site in Tipton County, creating 850 new jobs.”

That’s about 19 miles south of Kokomo.

“Once complete in 2014, the new plant will build our new nine-speed automatic transmission, which will be installed first in our Jeep Liberty successor, a key product that will debut later this year.”

That product is the Jeep Cherokee.

Marchionne continued, “Until then, our Indiana Transmission Plant I will build this transmission.

“The Tipton plant will be located in a building originally constructed several years ago to house a transmission plant to be operated by Getrag, and then was slated to house a solar panel maker. In each case, plans were scuttled before the facility was ever opened.”

Who could have imagined that Chrysler would be, in this case, trumping Getrag and a photovoltaic company? Arguably, it says something about the company’s commitment to transmission expertise and execution.

“So altogether, we are investing a total $374 million and adding 1,250 jobs to this area. When these plans are completed, Chrysler’s employment in the area will total more than 7,000 people.”

Two of those 7,000 are Brian Wade and Rick Warns. Wade is product engineer—Gears & Splines, Kokomo Transmission Plant. Warns is technical specialist, Indiana Transmission Plants I and II.

Funny thing. While Wade opens up with the observation: “The first key to making a good gear is starting with a good gear blank.” And while Warns says that one of the greatest challenges of producing good gears is getting good, trained people (“You can have the ability to make a very accurate gear, but when you’re trying to make it in high volumes, training of the workforce is very important. We have to be accurate to micron levels. A really big challenge for us is to get our workforce up to speed to operate all of the equipment. It’s not just a matter of walking up to a machine and pushing a button.”), before too long there is a reference to the author of Horologium Oscillatorium, a treatise published in 1673 by mathematician Christian Huygens.

Seriously.

Wade points out that Warns had done some research on the subject of gears, which brought him to Huygens’ work, which apparently was used by American inventor George B. Grant, who patented a spur hobbing machine in 1889. And as Wade notes, “On an external gear, almost without fail, hobbing is the chosen process because it is clearly the most economical, and it is very accurate. Even for one of the transmissions Rick is responsible for, the gear train is finished with hobbing. There are aerospace gears finished with hobbing.”

And yes, they both acknowledge that hobbing is generally a roughing process. Seems like technology has come a long way since 1889.

But typically there is rolling, shaving or grinding used. Wade says that what they do comes down to a few simple questions: “What is the product going to be used for? How much money are you going to spend on it? How are you equipped?” He adds, “With time and money you can do anything you want to do. But we have operating constraints as a business. If you violate the basics, that’s where you get into trouble.”

Among those basics, he explains, is the understanding of what happens when a blank goes through the processes to become a gear. Wade says, “There is a term that is widely abused when people talk about ‘heat-treat distortion.’” In point of fact, he explains, the steel blank begins in one phase, and through cutting and heat treating, there are phase changes. So far as he is concerned, “Heat-treat changes are part of the final geometry.”

This ties in with the issue of determining the purpose of the gear and the size of the purse that’s available for processing and equipment. Wade explains, “If you want the ultimate in accuracy, finish the treat after heat treating.” Grind them. But that’s expensive. So an alternative, he says, is to determine the effects of heat treating on the gear as machined, and then design the “green,” or non-heat-treated gear so that heat-treat changes are intentional.

Warns reveals what he calls “the big secret” about gears: You have to have design and manufacturing working together. Why?

“Gears,” Warns says, “are one big compromise from design through manufacturing. You have to end up with a design that can be manufactured, and it has to be tolerant to what your manufacturing process errors allow. What I am trying to say is that you can have a design that will function and transmit power, but is quite difficult to manufacture. There is a big balancing act that you are always doing.”

Brian Wade sums it like this: “When design and manufacturing work in harmony, you can achieve all the metrics you want. You can deliver products in high volume that are economical and suitable for the application. We like to say that if we do our jobs right, the customer doesn’t know we exist. We don’t want the gears to make any noise. We don’t want the gears to ever fail.”

Given the recent $374-million investment, the folks at Chrysler Kokomo are doing their jobs right—and then some.

The Lean, Systemic Approach to Gear Making

Helmut F. Jäger is managing director of Felsomat GmbH & Co KG. He is, says Richard Gilchrist, president of Felsomat USA (felsomatusa.com), the kind of man who looks at the way something is done, and then asks whether there isn’t a better way.

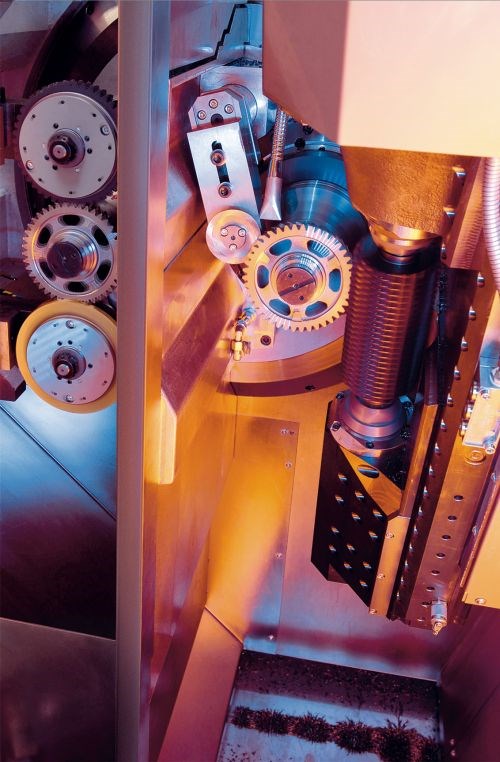

Historically, Felsomat has been known for its automation products—loading and unloading equipment—not for machine tools. And Jäger has looked at the whole machining process and determined that the way machining is ordinarily performed includes too much idle time, or time

when machines aren’t removing metal. So Felsomat entered the machine building part of the business, with an emphasis on using twin-spindles rather than one.

This, Gilchrist explains, allows cycle time reduction. “We’re not cutting chips any faster than anyone else,” he says. “We’re just eliminating idle time.

Richard Apanasiewicz, Felsomat process project engineer, amplifies, “The machines are 15 to 20 percent faster because we have two spindles. What others do with 12 machines, we do with eight.”

And the machines that they’re focused on are those that can transform gear manufacturing in a significant way.

Felsomat, which numbers Chrysler and ZF among its customers, has long been a technological innovator. And as it was acquired by Reishauer AG, gear grinding expert, in late 2010, its credibility in gear making has been burnished and its knowledge base expanded.

“The FlexLine concept,” Gilchrist says, “was designed to integrate the entire gear manufacturing process, from start to finish.”

Gilchrist explains that the typical approach in automotive gear manufacturing is one in which there is a vast amount of work-in-process that is likely to be spread far and wide.

That is, gear blanks are sourced from a third party. Then the gear making begins. Hobbing. Turning. Chamfering. Heat treating. Hard turning. Bore honing. Grinding. All generally performed in separate departments. Some companies actually send the gears-in-becoming out for heat treating.

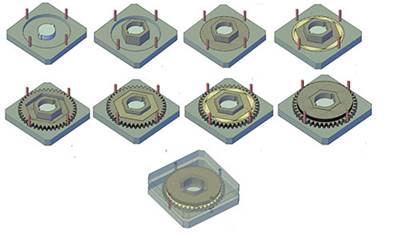

What Felsomat has done is to create a series of modules that can be integrated such that there is an integrated production system for gear manufacturing.

For example, there’s the FTC 180, a twin-spindle vertical turning center that can be used for both green and hard turning. The machine offers a chip-to-chip time of less than 1 second—that’s with loading/unloading being performed parallel to the processing. Its hard turning capability is said to provide the kind of precision achieved with grinding. However, the machine is also designed to be matched with another machine in the lineup, the Reishauer RZ 260, a finish grinding machine. The FTC 180 has a compact footprint (6 square meters).

Other machines in the FlexLine lineup are the FHC 180, a high-speed machine that performs hobbing, chamfering and deburring; the FLW, a laser welding center that was developed with laser expert Trumpf (trumpf.com); the Syncro-Therm, an in-process heat-treating system developed with ALD Vacuum Technologies GmbH (ald-vt.com); and the FPSH, a high-speed honing machine for hardened gears.

Rather than having processes performed throughout (or outside) a facility, the FlexLine approach is predicated on one-piece flow. An exception, of course, is the heat treating. Gilchrist says that in conventional operations there may be as many as many as 1,000 gears put in the oven, and there may be issues with the uniformity of heat treating, given the density of gears in the furnace. The SyncroTherm unit has up to six “hot zones” stacked one above the other. A limited number of gears are put on each of the part carriers; there are flat-panel radiators above and beneath each of the layers for uniform heating. Parts are vacuum carburized, then quenched. While this isn’t single-piece processing, it is still a comparatively small-batch operation.

“We try to make everything as compact as possible,” Gilchrist says. “When we work on a transmission program, we try to save 20 to 40 percent floor space.”

He goes on to explain that the implications of this can be significant when the cost of factory floor space and all it entails (everything from employees who staff the equipment to lighting and HVAC) are taken into account. “Our success normally comes when talking to someone in the organization who understands the total cost of building a plant—and the total cost of building a transmission.”

Patrick Seitz, Felsomat vice president, has another take on the importance of a highly efficient gear production system: “When you go from a five- to a 10-speed transmission, the number of gears is not just doubled; it’s more than that. So to keep up with the number of gears you need, cycle time is becoming more crucial. So we’re reducing that by minimizing the idle time of the machines.”

Ford’s High-Tech Gear Analysis

Ford Motor Co., at its Sterling Axle Plant in Sterling Heights, MI, where it produces the axle gears and axles for the F-series pickups, is deploying what it claims to be the first photogrammetric pattern reader (PPR) for the inspection of axle gears.

“PPR technology is the next evolution in quality control for our commercial trucks,” says David Gravel, an engineer in Ford’s advanced manufacturing group. “While traditional inspections of our axle gears ensure we’re delivering dependable, tough trucks to our customers, this new technology allows us to conduct our inspections faster, and at a level of detail the human eye just cannot discern.”

What’s more, the curvature of the hypoid gears used on the rear axle ring and pinion doesn’t allow inspectors to see both sides of a gear with a standard two-dimensional image.

The process starts by spraying the axle gear with a marking compound evenly across its face.

Next, the gear is rolled to create the contact or mesh pattern. Infrared lighting and line-scan cameras are then deployed to check the physical characteristics of each gear tooth. In all, 9,000 two-dimensional images measuring 1024 by 1 pixels are stitched together to create a three-dimensional image of the gear. This allows a precise understanding of the location of each tooth on the gear.

Since the system was deployed, two to five parts out of 1,000 inspected with PPR are typically scrapped as they fall outside of the required tolerances. The system was developed with Ford by Automated Vision and ATM Automation (atmautomation.com).

According to Ford, it plans to install more systems like this in its axle manufacturing plants around the world.

Read Next

Composites in Hybrid Gears

Replacing steel with carbon fiber composites yields promising results.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)