Composites in Hybrid Gears

Replacing steel with carbon fiber composites yields promising results.

Share

It goes without saying that the heaviest components on any aircraft are easy targets of weight reduction. It also goes without saying that any effort to reduce weight on an aircraft must not compromise reliability or safety. On a rotorcraft, one of the heaviest modules is the drive system that turns the rotors, accounting for about 10 percent of the total weight of the craft. And the drive system, of course, is a major consumer of gears, which are typically fabricated from steel.

The NASA Glenn Research Center (Cleveland, Ohio) has begun an effort to look more closely at material use in gears, and in 2012 reported on evaluations of a hybrid composite/steel gear design that showed the possibility to reduce gear weight by as much as 20 percent without sacrificing gear performance.

The effort was led by Dr. Robert Handschuh at NASA Glenn, with assistance from Gary Roberts, Ryan Sinnamon, David Stringer and Brian Dykus. They focused their efforts on replacement of steel with carbon fiber composites in the web of the gear between the gear teeth and the metallic hub that attaches to the torque-applying shaft. The goal was to fabricate a composite hybrid gear and then test it against its all-steel competitors, checking in particular for vibration, noise and long-term durability.

Ultimately, the results proved positive. Testing demonstrates that hybrid gears can operate over a long period of time, with decreased weight, and, given the right manufacturing processes, less noise and vibration.

Fabrication

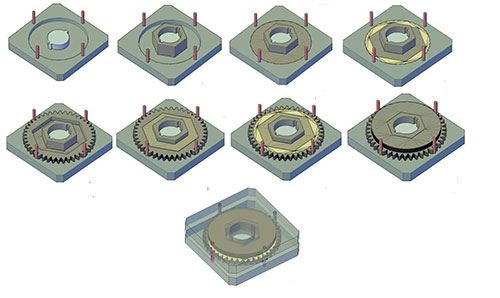

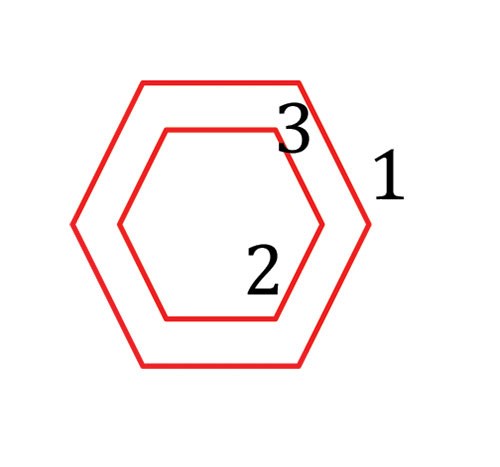

The hybrid gear NASA Glenn devised was fabricated from an all-steel aerospace gear in which the steel between the hub and the gear teeth was electro-discharge machined out in a hexagonal shape (Figure 1). This gap, known as the web, represented the largest mass of the gear and thus was the best candidate for replacement with a composite.

The gear tested had 42 teeth, measured 3.5 inches (89 mm) in diameter and 0.196 inch

(5 mm) thick. The trick was to fabricate a composite web that reconnected the hub, web and teeth in such a way as to maintain dimensional accuracy of the teeth. This was done by placing the hub into the center of a tooling fixture that featured a flat steel plate with a circular cutout the same diameter of the gear’s web (see image on page 23).

A series of aerospace-grade carbon fiber fabric plies pre-impregnated with an epoxy resin was placed around the hub. The carbon fiber plies, supplied by Toray (Tokyo, Japan), are branded T700SC. The weave of the carbon fiber is visible in Figure 2 and was placed in 0- and ±60-degree orientations so as to optimize material strength. A total of three circular “prepreg” webs were fabricated, each composed of 12 plies of carbon fiber. One web surrounds the hub. The other two sandwich the first.

The tooth ring (minus the material excised from its center) was placed in the middle of this sandwich, inside the locating rings on the tooling fixture, to help maintain dimensional accuracy. A bond in the form of an adhesive strip connects the outside composite webs to the tooth ring to unify the entire structure. When completed, the hybrid gear weighed 0.7081 lb (0.32 kg), 20 percent lighter than its AISI 9310 steel counterpart, which weighed 0.8847 lb (0.4 kg).

Dynamic Testing

The next step for NASA Glenn was to conduct a series of tests to assess the abilities of the hybrid gear against the all-steel standard. Two types of dynamic tests were conducted to determine if hybrid gears might be considered as possible candidates in rotorcraft drive systems. The first test assessed vibration and noise using four speeds and four levels of torque; the second was an endurance test designed to run for a large number of meshing cycles.

The dynamic tests for noise and vibration used a test gear box in which two mating gears rotate against each other. The gear on the left side of the test rig is the driving gear, while the gear on the right side is the driven gear (Figure 3). All vibration measurements were made on the driven gear. The following configurations were used on the test rig:

- All-steel gears on both sides

- Hybrid gear left side, all-steel gear right side

- All-steel gear left side, hybrid gear right side

- Hybrid gear both sides.

The four configurations employed were 2,500, 5,000, 7,500 and 10,000 rpm at 50, 100, 200 and 300 psi load pressure. Vibration was measured using an accelerometer on the driven gear and expressed in Gs. The noise level was recorded using a handheld sound level meter at a distance of 1 inch (25.4 mm) from the test gearbox cover.

Test data showed that among the four configurations tested, vibration was greatest (15.933 Gs) in the steel-on-steel combination at 10,000 rpm and 300 psi load. The maximum vibration in the other three configurations at 10,000 rpm/300 psi was: composite (driver)-on-steel combination = 13.016 Gs; steel (driver)-on-composite = 7.025 Gs; composite-on-composite = 12.766 Gs.

In sound testing, the steel-on-steel combination produced the “loudest” measurement of 103 db at 10,000 rpm, but the composite-on-composite combination wasn’t far behind at 100 db, also at 10,000 rpm. In general, the data were mixed as to how consistently the composite material might be able to attenuate vibration and noise. The paper’s authors attribute this to manufacturing imperfections in the composite that might be corrected in a more robust fabrication process. For example, no grinding of the gear teeth was performed post-attachment of the composite. In addition, the composite curing actually reduced the backlash of the components due to stretching of the metal outside rim; the backlash also was not consistent around the gear.

NASA Glenn also conducted long-term testing of the hybrid gear to assess performance over an extended period of time. The hybrid gears were run for more than 300 x 106 revolutions at 10,000 rpm and 250 psi torque load with an oil inlet temperature of 120°F/49°C. The hybrid gears, the authors report, operated without any problem during this extended period.

NASA Glenn ultimately concluded that hybrid gears show promise given their ability to operate over a long period of time. Further, power-to-weight ratios aboard a rotorcraft could be possible with the replacement of steel webs with composites. Finally, reduced noise and vibration would be expected using a hybrid gear if manufacturing processes are refined to produce aerospace-quality gears.

Read Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)