The Anatomy Of An End Mill For Aluminum

By using specialized cutter geometry and incorporating smooth finishes with tough coatings, Toolmex Corp., created an end mill well suited to cut aluminum aggressively. This tool called the "Mako" is part of the SharC line of specialized tools from the same company.

Share

There are four barriers to aggressively milling aluminum: chatter, chips adhering to the tool, the abrasiveness of the material and controlling the large volume of chips. Cutting tool manufacturer Toolmex says all of these challenges can be addressed with the right tool design. The company’s “Mako” end mill (part of its “SharC” line) is an example of a tool designed specifically for high metal removal rates in aluminum. Different aspects of the tool were engineered for the separate difficulties of machining aluminum quickly.

To attack the chatter problem, the flutes of the SharC Mako are not evenly spaced. Rather, the tool has two long flutes and two short flutes. This uneven spacing prevents regular flute impacts from creating harmonic vibration, which can cause chatter in the walls and floors of the cut.

Aluminum’s natural ductility and malleability make it generally easy to work with and attractive for machining. But under aggressive cutting conditions, it becomes gummy, sticking to flutes and causing the ruin of many an end mill. One typical practice to keep this from happening is increasing the concentration of the coolant or switching from water-soluble coolants to oil-based solvents. The Toolmex design addresses this problem by decreasing the tool’s surface finish to 15 Ra. This requires extra finish passes when grinding, but results in a tool that can avoid sticky aluminum chips using common coolants and concentrations, the company says.

Oxides left in the aluminum from the melting or casting process are a source of abrasiveness in all aluminum grades. In fact, many industrial abrasives contain the same material—aluminum oxide. Cast grades of aluminum can contain aluminum oxides left over from the sand-cast process and can also contain the more aggressive silicon oxide. To combat these abrasives in aluminum parts, the Toolmex design uses TiAlN coating with a high concentration of aluminum oxide to essentially fight fire with fire.

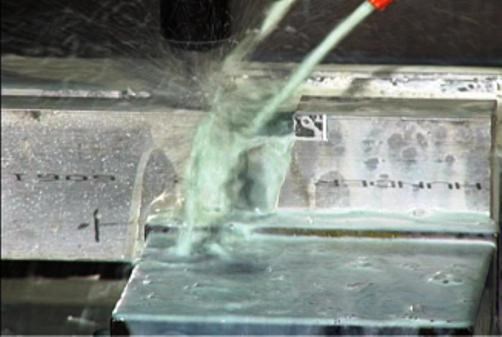

Finally, the Mako end mill is designed to promote efficient chip evacuation. During chip formation, chips tend to curl, taking up more space after they are cut than before. Because the chips tend to stay in the flutes, the chances are high that chips will be cut more than once when using conventional end mills. These chips are also tougher to cut the second time because they appear on the flutes in a random manner. The Toolmex design is able to address this thanks to the fact is has three flutes instead of four. The odd spacing makes it possible to grind what the company calls “gash rollout” into the bottom of the end mill. Gash rollout offers extra evacuation area, picking up loose chips from the bottom of the end mill and forcing them out the top.

This specialized engineering results in an end mill that can plunge, slot, profile, rough and finish in a single pass. According to the company, the benefits over a more conventional cutter include more parts per end mill, reduced cut time and increased throughput.

Related Content

-

Emuge-Franken End Mill Wins ANCA's Tool of the Year Award

Emuge-Franken received the award for its specialized tool based on the new Cera-Cut end mill design.

-

OSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

.png;maxWidth=300;quality=90)