Technologies for More Effective Medical Component Manufacturing Seen at MD&M West 2018

Advancements in 3D printing, automation and inspection technologies were prominent at this year's Medical Design and Manufacturing West show.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

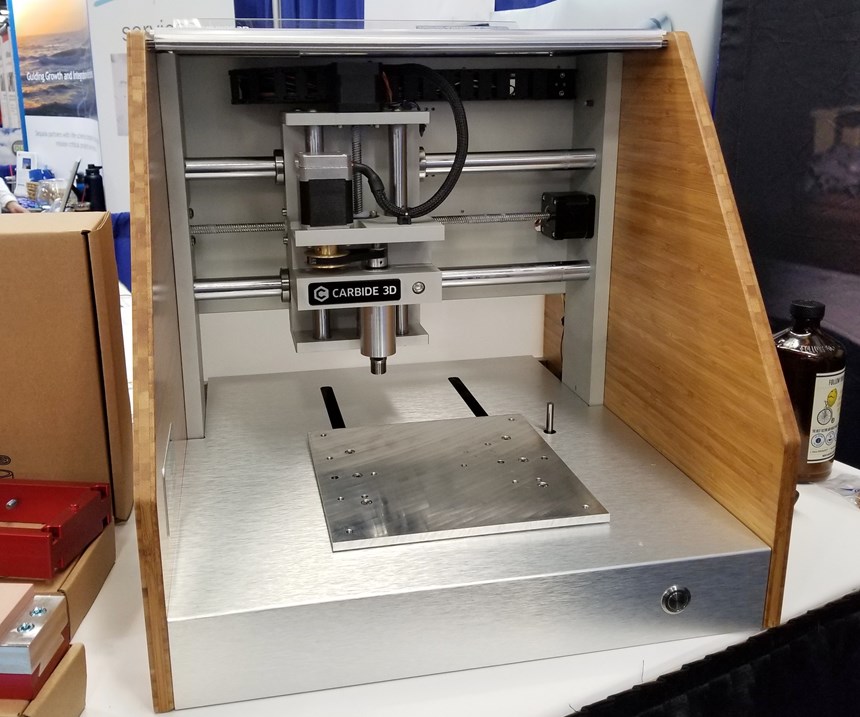

View MoreThis year’s Medical Design & Manufacturing Expo West (MD&M West) show in Anaheim, California, featured various new technologies that can enable manufacturers of medical components to become more efficient and effective. From 3D-printing hardware to automation solutions to tabletop CNC milling machines, this trade show had a lot to see.

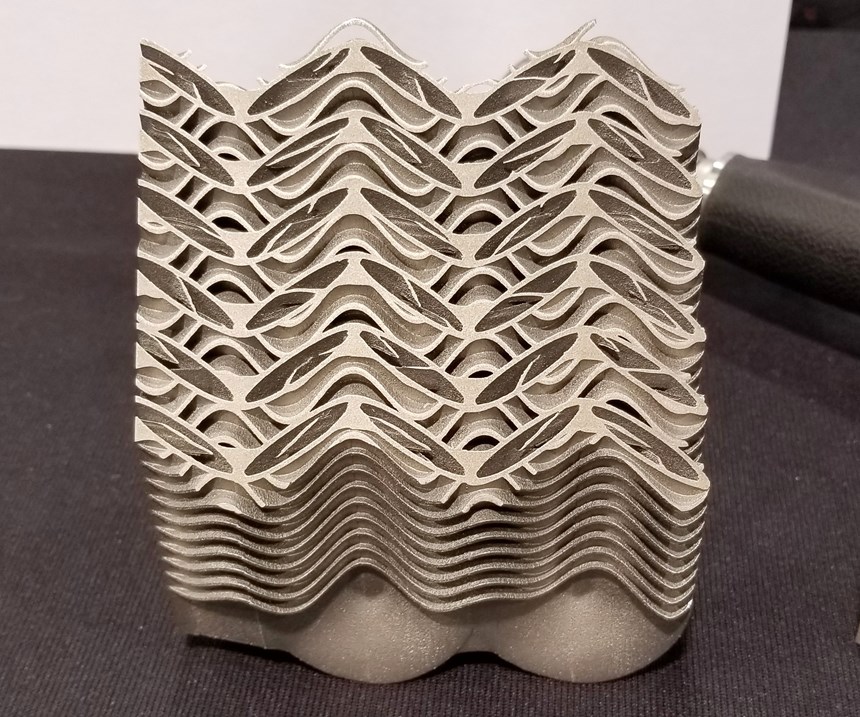

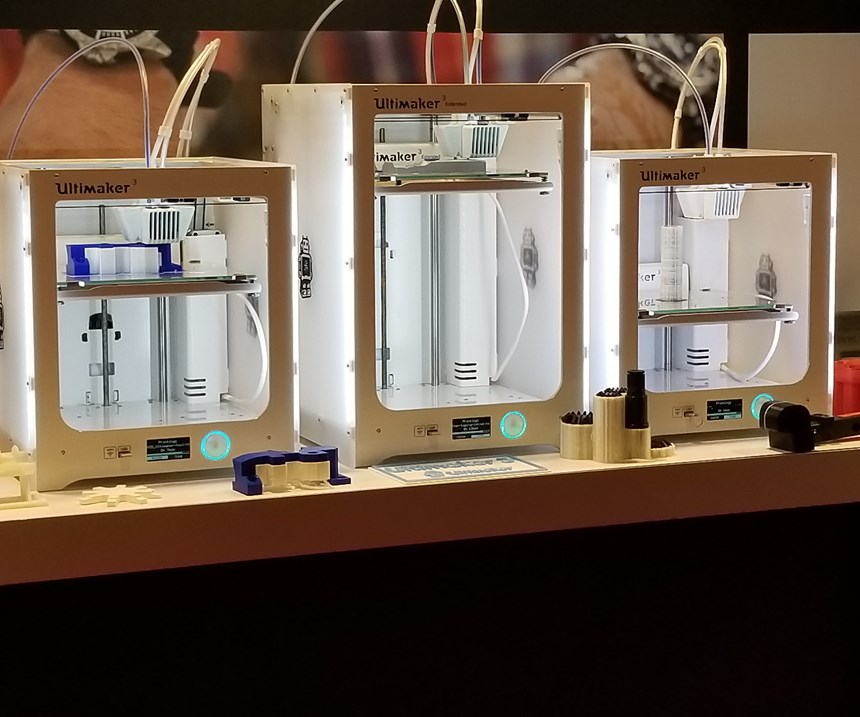

Walking the floors of the expo, it was clear that additive manufacturing has thoroughly infiltrated the world of medical manufacturing. Nearly every small-parts producer promoted its additive manufacturing capabilities, and many manufacturers of 3D-printing solutions exhibited there. Customizable implants and rapid prototyping capabilities seem to be highly valued in this corner of manufacturing. According to Ultimaker North America President John Kawola, the benefits of rapid prototyping are only just being explored, and there is a lot of potential to unlock.

It seems the world of medical manufacturing runs on two concepts: precision and cleanliness. Medical devices and implants must meet exacting specifications without any environmental contamination, and I feel much more at ease walking into the doctor’s office after seeing how exacting the medical standards can be. For example, Darren Bjork, vice president of medical-parts manufacturer Metro Mold & Design Medical (MMD Medical), told me the company has made great strides in cleanroom machining. I also stopped by the Quality Vision International booth and spoke to Marketing Manager Alyssia TenBrock, who showed off the company’s multisensor array: an inspection device that combines a laser, touch probe and visual scanner. The system speeds the workpiece-scanning process by eliminating the need to recalibrate or change-out sensors, a notable time saver in an industry that demands precise tolerances with literally life-and-death consequences.

Onshape drew a significant crowd at MD&M West as it released the public beta version of its browser-based CAM software VisualCAM, developed by MecSoft. A cloud-based CAM system, the software enables users to share CAM iterations using highly secure, password-locked internet links, avoiding the need to download or upload files, not to mention eliminating the expensive hardware needed to store files. The system also saves iterations of a design, so file management is said to be of no concern.

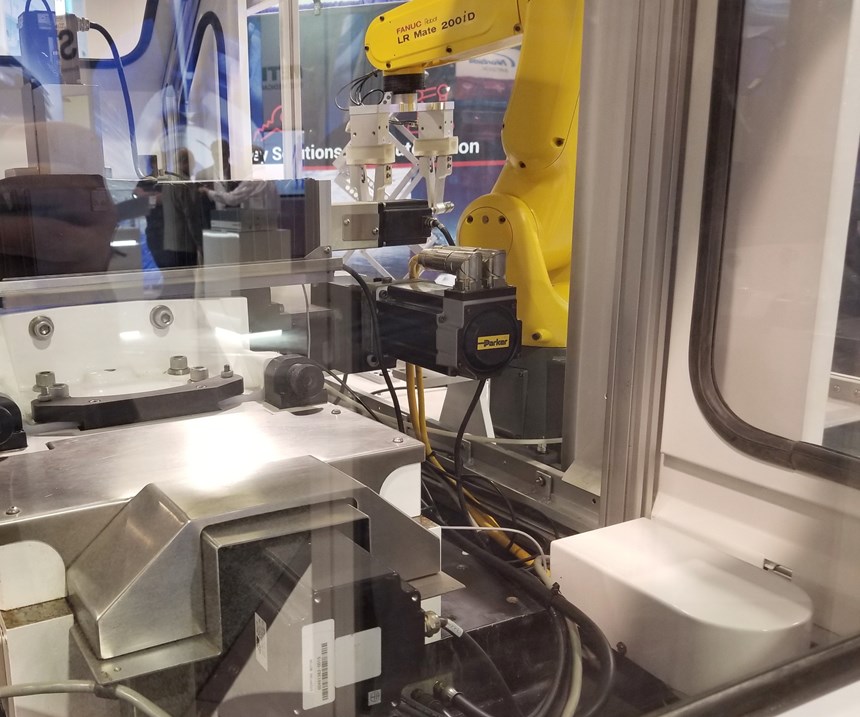

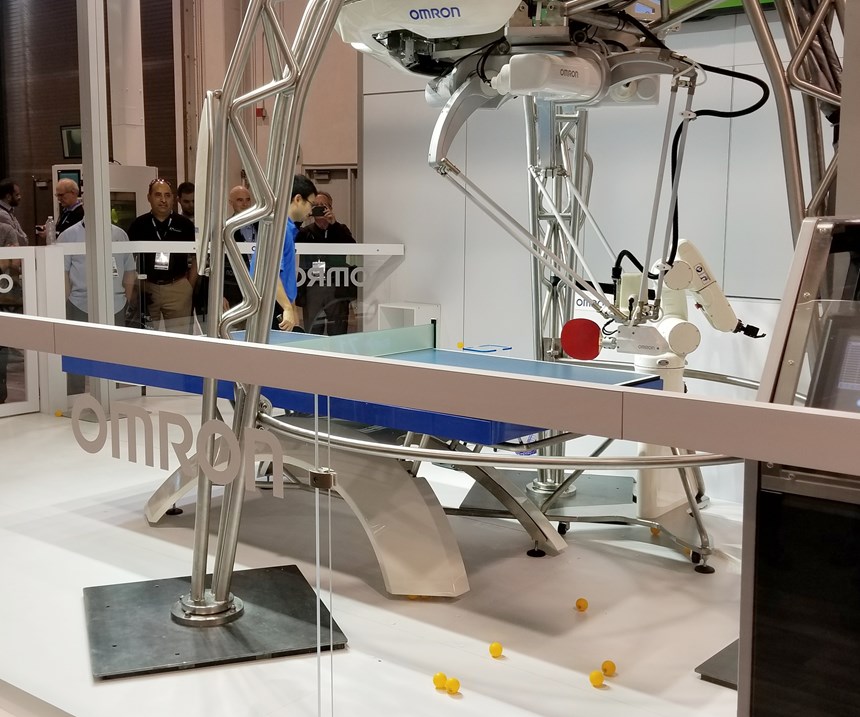

In the same hall as MD&M, the Automation Technology Expo (ATX West) showcased automation solutions for manufacturing. Omron had a large display area showcasing its offerings. Its most prominent display, however, was Forpheus, the ping-pong-playing robot. While it may seem trivial, the technology that went into Forpheus is intensive, including visual scanners; swift, precise movements; and machine-learning capabilities. The extensive scanning suite is capable of reading human facial expressions and body language to judge skill, using that information to teach the human player to play better ping-pong. The company uses this technology in the rest of its robotics and scanning technology, providing adaptable and precise automation solutions.

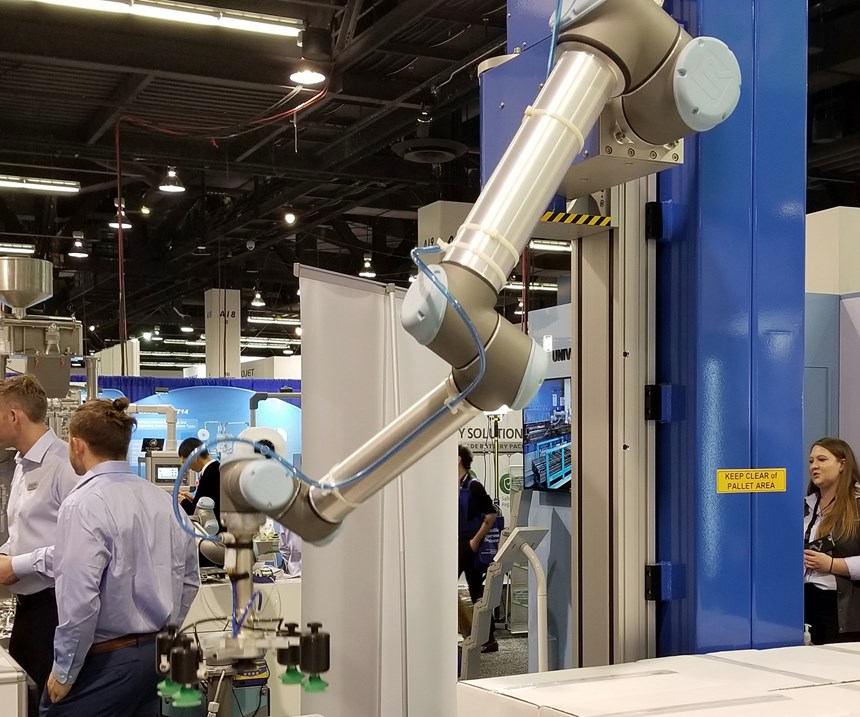

Universal Robots (UR) has a different approach to automation. Instead of focusing on achieving the highest speed and precision possible, the UR collaborative robots (cobots) use sensor technology that enables them to function safely alongside humans in a shared area, unlike conventional industrial robots that operate autonomously inside a safeguarded cell. Sensors detect when the cobot unexpectedly contacts an object, be it a person or something else. They then immediately stop their motion to prevent injury or damage. Moreover, the UR cobot is designed to be easy to program—a feat that was done by booth visitors in just a few minutes, making it easy to adjust to various jobs in a low-volume machining environment. The cobots on display included a “zero-footprint” model that can attach to girders to perform functions without interfering with other shop activities. According to UR Sales Manager Craig Tomita, the cobot can also attach to a rail system to perform part loading/unloading for multiple machine tools.

MD&M West, along with ATX West, provided numerous examples of the dynamic landscape of manufacturing today. Whatever problem a shop may be facing, be sure that technology providers are in heated competition to find the solution.

Related Content

Ametek EMC Laser Cutting System Offers Through-Part Cooling

The new laser cutting system offers comprehensive Swiss machining capabilities, as well as through-part cooling and automatic part-handling options.

Read MoreTungaloy-NTK PCD Grade Optimizes Dimensional Accuracy

The DX200 is an effective tool for machining application-specific components that demand high levels of material purity, such as metal medical implants and sputtering targets for semiconductor applications.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreMikron Milling Tool Suppresses Machining Chatter

IMTS 2024: The CrazyMill Cool CF milling tool features chatter suppression during machining, especially on thin-walled parts, which enables smoother cutting.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More