Taking The Plunge

It doesn't take sophisticated technology to perform plunge roughing effectively. In fact, if you are making due with a less effective machine, plunge roughing deserves even more serious consideration. (Includes video.)

Share

See video of plunge roughing applications

The great thing about plunge roughing is that you don’t need a new machine tool in order to do it very well. In fact, the process is arguably better on older machines. Capabilities such as high speeds and precise interpolation are not needed. If the machine can drill, it can plunge rough. Therefore, the technique provides a way to realize high value from an old machining center that may have receded in relative performance over the years.

Is the machine slow, for example? Or is the machine so worn that its precision and power are suspect in the X-Y axes? These shortcomings don’t matter. Plunge roughing is a technique that achieves high metal-removal rates using moderate feed rates combined with passes that are taken only along the Z-axis—the direction of the spindle and tool.

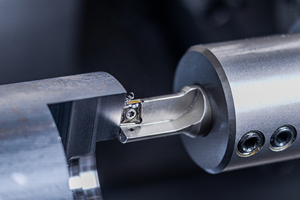

New technologies have been applied to plunge roughing, two examples of which appear in the colored boxes on the following pages. One is a drill that can plunge rough, where typically a milling cutter is used, because the drill is able to machine an interrupted hole without wandering. Ingersoll Cutting Tools offers this tool. The other technology, created by Ingersoll along with WorkNC developer Sescoi, is a CAM algorithm for retracting the plunge-roughing tool away from the stock to preserve the life of the tool. Three Ingersoll representatives recently served as sources for this article: milling products market manager Konrad Forman and product managers Michael Dieken and William Fiorenza Jr. Together, they offered advice on how to apply plunge roughing and where the technique makes sense.

First, they say, new cutting tool or toolpath technologies of the sort just described are not necessary. In the right applications, they may be helpful, but plenty of shops perform plunge roughing using technology they already have at hand. The main requirement for plunge roughing is a tool that can cut effectively when it “plunges” straight into the workpiece like a drill. Plunge roughing consists of removing stock entirely through a series of these drill-like passes. Instead of creating a series of holes, though, the plunges overlap to clear the material away. Some milling tools are designed specifically to cut on their centerline and achieve their best efficiency, but a more conventional tool that happens to be able to cut in Z in addition to cutting in X-Y can also do the job.

Similarly, some CAM systems are able to automatically generate plunge roughing routines tailored to complex volumes. However, for more simple volumes, any basic CAM system or CNC macro for programming drilling moves can be used to generate at least a basic plunge roughing routine, with the spacing simply chosen so that these passes overlap in a way that actual drilling passes never would.

This, then, is the essence of plunge roughing: Material is not smoothly and continuously machined away as it might be along the X-Y plane. Rather, it is hogged out exclusively through advances and retreats.

The method seems clumsy. When would this method be more effective than conventional milling?

Actually, in a number of cases, the sources say.

When To Use

Plunge roughing is almost exclusively a roughing process. The overlapping plunges leave behind cusps or webbing that must be removed through follow-up machining. This semi-finish or finishing work does require X-Y milling. Therefore, plunge roughing can be compared only to other approaches to roughing.

When making the comparison, Mr. Forman says, the primary consideration is simply which process can “pull more cubes.” That is, the better process achieves a higher metal-removal rate in cubic inches per minute for the part, setup and machining platform in question. In general, plunge roughing is likely to remove the material more rapidly in each of the following cases:

- Deep pockets or deep slots. A machine that mills in X and Y will need to slow down or take lighter cuts as it uses progressively longer tooling to reach farther into a deep pocket or deep slot. A machine that is plunging does not have to slow down in the same way. That’s because the stiffness in X-Y changes as the tool overhang changes, but the stiffness of the same system along the Z axis can remain the same.

- Where chatter matters. An offshoot of the case above, plunge roughing should be considered in any relatively long-reach application in which chatter limits the cutting conditions. Where stiffness is poor, the shop might resort to tame cutting conditions to prevent chatter from setting in. Plunge roughing can bypass this chatter because the improved stiffness along the Z axis changes the system’s chatter characteristics. Similarly, plunge roughing can be useful close to thin walls, where chatter is likely to damage the workpiece.

- Lighter-duty machines. Another case for plunge roughing involves machining centers that are engineered for economy. The Z-axis is the stiffest axis for most machining centers, and on some lighter-duty machines the difference in stiffness between X-Y and Z can be pronounced. For more aggressive roughing applications, try plunge roughing to see whether this approach can let the machine remove material much faster.

- Older machines. One final case where plunge roughing tends to perform well involves the older, slower, well-worn machining center that is typical among the mix of machine tools in any long-established shop. Because plunge roughing involves only simple straight-line moves along the stiffest axis, a machine such as this can remain effective for plunge roughing even after age and wear have rendered it much less effective for conventional milling. If a shop’s capacity constraints demand that roughing needs to be performed on this older machine, then try plunge roughing as a way to recapture some of the machining glory that this machine may have lost in its other axes over time.

Related Content

Sandvik Cormant's End Mills Eliminate Machining Chatter

The company’s CoroMill Dura line of solid end mills has been extended with aluminum-specific tools.

Read MoreGWS Tool Group End Mill Provides Dynamic Milling

Eastec 2023: The Hurrimill AT4 all-terrain end mill features radial-end gashing, which enables drilling, steep ramping and aggressive helical entry.

Read MoreTungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More.png;maxWidth=970;quality=90)