Surface Grinder Improves Machine Tool Components

Moore Tool replaced its dated surface grinder with a new model from Okamoto, which included features and options that have helped the company improve accuracies and surface finishes on components of its jig grinders and diamond-turning equipment.

Share

When it comes to purchasing machine tools, some of the most discerning companies are the ones that make machine tools themselves.

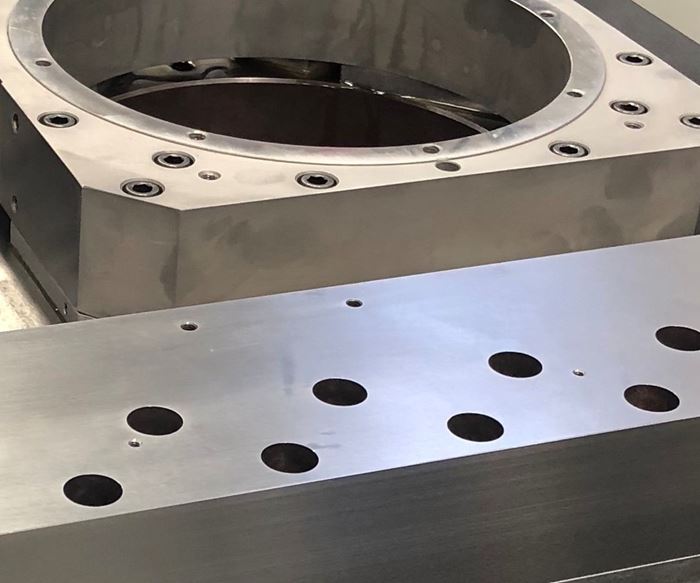

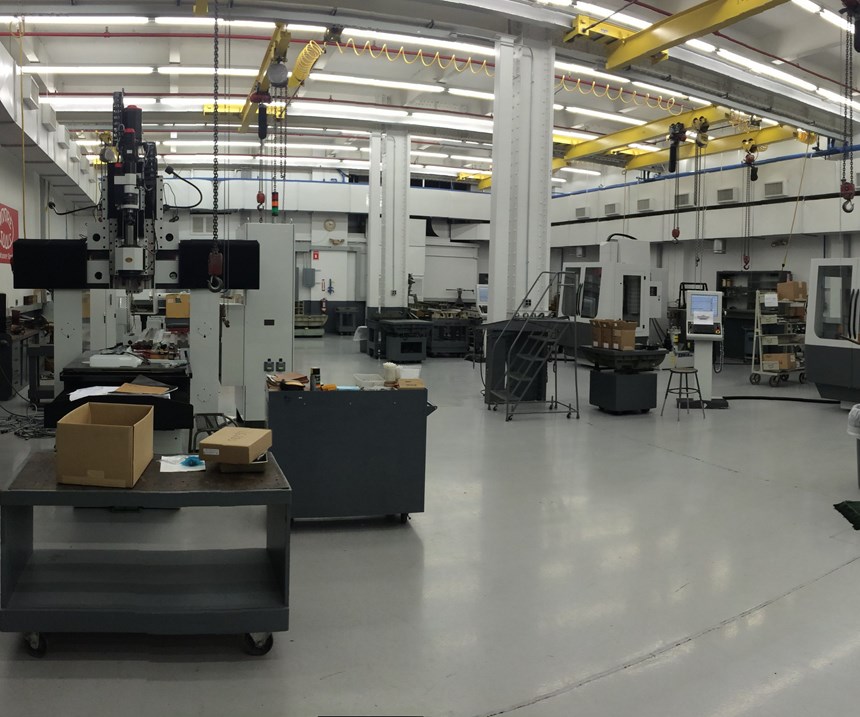

One such company, Moore Tool, is a fourth-generation, family-owned business that designs and manufactures jig grinders and diamond-turning equipment. The Bridgeport, Connecticut, company also has a contract machining division with capabilities that enable it to take on a range of challenging jobs, including precision die sets for metal stamping and injection-blow-molding applications, aerospace and defense parts, punches and dies for thermoforming and injection mold plates. In addition, it performs all types of grinding, including jig grinding.

The company had been using a dated surface grinder for many jig grinder and diamond-turning equipment components, including tabletops, bases, rails and other mounting surfaces, as well as parts from its contract machining division. Many different part sizes and materials would come across this machine. “On any given day, we could be grinding cast iron, aluminum and mild A36 steel,” says Manufacturing Manager Chris Dolny. “We’ll do a 4-by-2-inch part, and then we have a 30-by-70-inch part the very same day,” he adds.

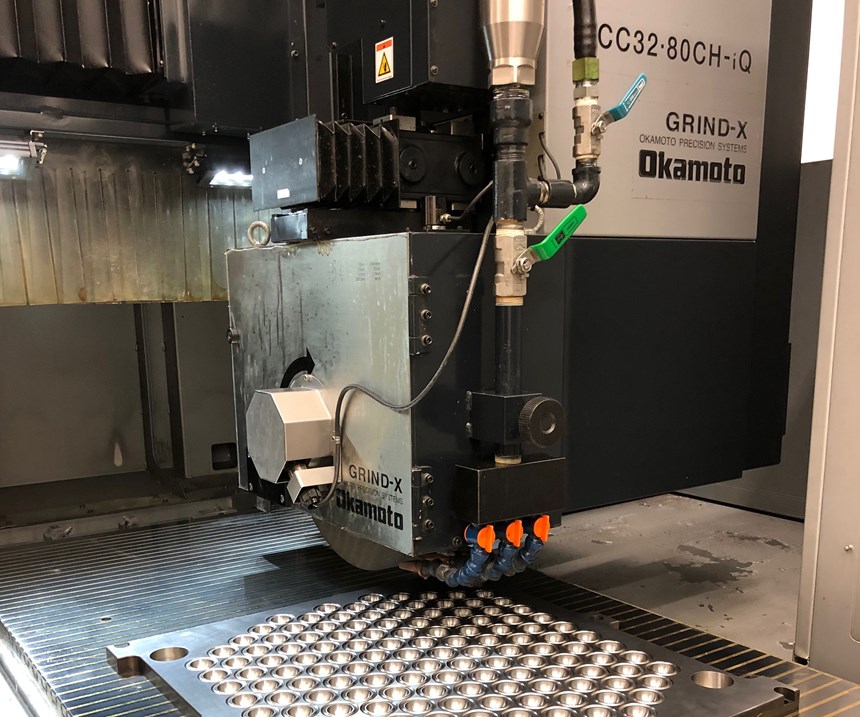

While Moore Tool’s dated surface grinder was sufficient, a good bit of manual lapping and/or scraping was still required to generate the proper geometry and surface finish for certain components. That, combined with subpar performance and reliability issues, led the company to look for newer surface-grinding technology, ultimately purchasing an ACC3280CHiQ from Okamoto (Vernon Hills, Illinois). This new machine can grind parts to a better geometry and finish, which has reduced secondary, manual operations. It has also sped the production of jig grinder and diamond-turning components, increasing the company’s overall competitiveness in that market.

Although the surface grinder the company had been using was very old, the decision to replace it was not easy. “It took us a few years to make this decision to invest in new surface grinding technology,” says Newman Marsilius IV, Moore Tool’s vice president and general manager. In fact, the company made the decision just in time. On the same day the new machine’s purchase order was placed last year, the old machine went down with a fatal electrical error. “Luckily, Okamoto was bringing in a machine from Japan, so the lead time was less than 6 weeks,” Mr. Marsilius says. Moore Tool moved quickly to prepare its facility for the new machine. It renovated a room for it, installing air conditioning to keep the room’s temperature to a constant 68°F and poured a special deep foundation with rebar to isolate the machine from nearby production area vibrations.

The ACC3280CHiQ is a double-column-type surface grinder with a cast iron base and 30-horsepower spindle. According to Okamoto, this is nearly three times the power as conventional double-column surface grinders. Moore Tool wanted the new machine to have a table size and travels that were similar to the old machine. The ACC3280CHiQ’s table measures 30 by 80 inches and the distance from grinding wheel to top of table is 23.5 inches. “We grind a lot of parts that consume most of the table size,” Mr. Marsilius says. That said, because the company also grinds much smaller parts, having large table capacity offers the flexibility to run a variety of part sizes.

That, however, is where the similarities between the two machines end. Moore Tool’s ACC3280CHiQ surface grinder has standard features and options that have enabled it to increase grinding quality, efficiency and speed. These include:

Conversational control. Okamoto’s iQ touchscreen control was a major selling point for Moore Tool. It can be programmed conversationally, offering an intuitive interface for machine operators who use it to set up parts and write their own programs at the machine. In fact, operators were writing programs and running jobs after only a couple days of training from Okamoto. It also stores programs, which is useful for repeat jobs. Mr. Marsilius says that the old surface grinder’s control had been retrofitted at some point, but its software was very basic. “The conversational control was a huge step up,” he says.

Coolant-delivery system. Moore Tool also purchased a Grind Bix coolant aeration system from Okamoto, which produces ultra-fine bubbles to enable the coolant to get into the grinding wheel and part to assist part cooling and reduce wheel wear and part surface warpage. According to Okamoto, this system permits cutting in-feeds ranging to 0.004 inch. Mr. Marsilius says it has enabled Moore Tool to rough-grind parts more aggressively and has helped produce better surface finishes.

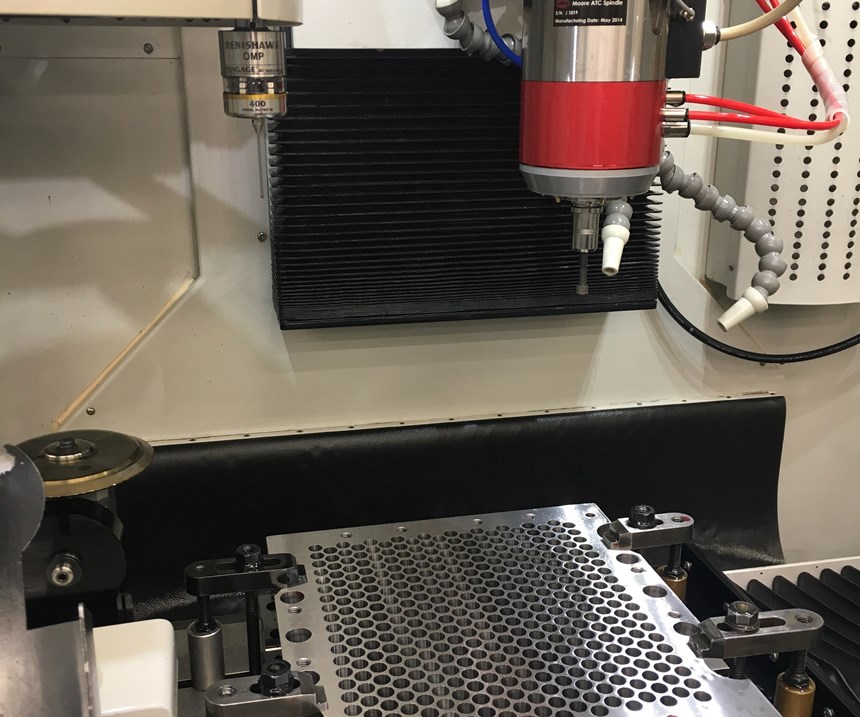

On-wheel balancing. The new surface grinder also has an SBS automatic wheel-balancing system from Schmidt Industries. After the operators mount the wheel, it goes through a hydraulic balancing cycle on the machine. This system also enables continuous, in-process dynamic balancing during grinding, which improves surface finishes.

Electropermanent magnetic chuck. Okamoto recommended an electropermanent magnetic chuck to go with the grinding machine. Because the electropermanent magnet does not produce as much heat as a standard electromagnet, thermal deformation is reduced and the overall accuracy of the system is increased. “It has given us very good results holding for flatness to microns and parallelism to spec,” Mr. Dolny says.

Automated dressing cycle. The machine automatically calls up dressing cycles per parameters set in the control that are based on the amount of material removed after the previous dressing cycle. After the wheel is dressed, the wheel size is automatically updated in the control, and the programs are adjusted to compensate for the new size. (The machine can compensate for both table-mounted and overhead-mounted dressers.) The machine then automatically moves the wheel to 0.0001 inch above the part surface and resumes the grinding operation without operator intervention.

Teach feature. Operators can use the grinding wheel to “teach” the machine and set the grinding envelope for new parts. Operators position the wheel at one edge of the part to record that position, and then move it diagonally to the opposite corner to set the grinding parameter. The wheel then moves down until it touches the part to set the zero on the Z axis. Users can also store these parameters for later use.

The quality of the parts coming off the new machine is much higher than the quality of parts produced by the old machine. Mr. Dolny says that the best surface finish they were able to achieve on the old surface grinder was 16 microinches Ra, but the new surface grinder gives them surface finishes of 8 microinches Ra and lower for some materials.

Mr. Marsilius sums it up this way: “The new machine is allowing us to make parts more efficiently and with better geometry in less time, so it ultimately makes our products a little less expensive and maybe a little bit more competitive in the market.” He adds that the company’s progress has been incremental, but it is slowly and steadily continuing to improve. Based on the improvement Moore Tool has made in the past year, it is considering adding a medium-size Okamoto grinding machine to accommodate parts that are too large for its smaller grinding machine, but too small for the ACC3280CHiQ.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)