Subscription Pricing For DNC

With this new DNC product, users no longer have to pay an up-front cost for the hardware and software. Instead, they pay only an annual fee-in essence a subscription to DNC.

Share

Takumi USA

Featured Content

View More

Distributed numerical control is nothing new.

And to John Richardson, this is a significant point. Mr. Richardson is CEO of a company with DNC to sell—Cimnet Inc. of Robesonia, Pennsylvania. He says both the market and the technology are mature. Shops that need DNC generally understand what they're getting, and Cimnet's system is little different in features or performance from the systems other companies offer. As a result, customers continue to downgrade what they are willing to pay for DNC. They treat it like a commodity.

It's not quite a commodity, however. In addition to price, one other factor figures prominently in buying decisions: the customer's opinion of the supplier company. After it's installed, the DNC system still needs to be supported.

In an attempt to address these priorities of DNC users, Cimnet is experimenting with a new option for its DNC product. It's not a technology option, it's a pricing option. With Cimnet's product, users no longer have to pay an up-front cost for the hardware and software. Instead, they pay only an annual fee—in essence a subscription to DNC.

Traditionally, a customer for a 16-machine DNC installation might pay $5,000, combined with a 15 percent annual maintenance fee. That option is still available. Under the new option, customers skip the up-front cost altogether, while the annual fee goes up to 20 percent.

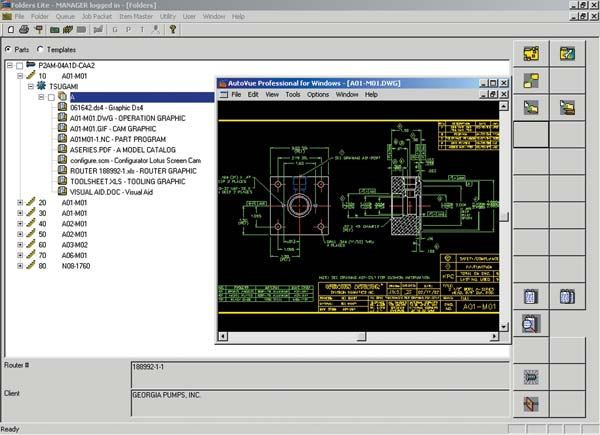

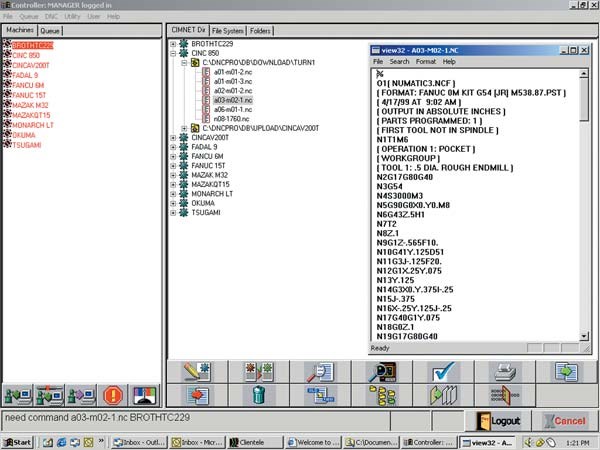

This option applies not only to the DNC system, but also to "Folders Light," the company's introductory-level document management program that allows part drawings and setup instructions to be viewed electronically on the shop floor. The subscription fee includes telephone technical support and hardware maintenance, as well as ongoing software upgrades so installed systems remain current.

"From a financial standpoint, the choice of payment option will be a no-brainer for most of our customers," Mr. Richardson says. The company began offering the new option in early October. In the first year, he expects three-quarters of new DNC customers to choose it.

And throughout the first year, Cimnet will lose money on each of those customers. One year's annual fee is not enough to cover the initial hardware and software costs.

Balancing the delayed break-even point are at least three reasons why Mr. Richardson says the company decided to go with this model:

One is the message it sends. The arrangement puts Cimnet in a position where it can only profit by sticking around and continuing to support the product.

Another reason is the chance that DNC might help the company build relationships with large manufacturers who might be candidates for a manufacturing execution system, which Cimnet also offers.

A third reason relates to small shops. With these shops, the purpose of the subscription model is simply to make the sale. Many small shops that might benefit from DNC can't afford the initial cost. The subscription model offers a way to include these users. Given the mature market for DNC, the potential pool of new customers that small shops represent is very attractive to a DNC supplier.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)