Probe Has Right Touch for Five-Axis Aerospace Parts

On-machine measurement is critical at this aerospace manufacturer, which needs to ensure that features of already high-value parts are within specification before performing additional operations. With the RMP600 strain-gage probe from Renishaw, the company has eliminated the delays that come with measuring on a true CMM.

Share

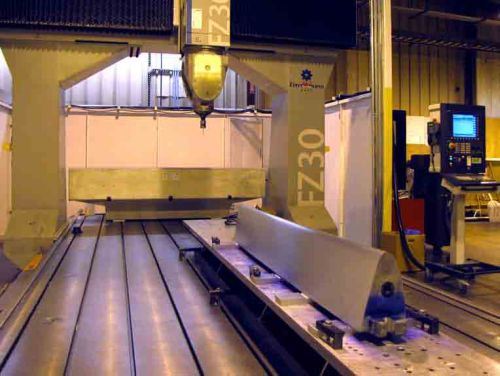

Flat lines and straight surfaces are rare at Triumph Fabrications’ Shelbyville, Indiana facility, where there’s hardly a part or die that is not sporting a parabolic, compound-curved or cone shape. To facilitate lean manufacturing, the aerospace stretch-forming company’s CAD/CAM department has refined its ability to rapidly and precisely measure such parts while still fixtured on machine tools.

However, obtaining the refined “touch” needed for consistent and accurate on-machine measurement required upgrading the machine tool probe on one of the company’s five-axis Zimmerman portal mills to a strain-gage-based RMP600 from Renishaw (Hoffman Estates, Illinois). With no lobing and a repeatability of 0.00001 inch (0.25 µm), the strain-gage probe maintains accuracy when triggered from any direction after a one-time calibration routine.

Combined with Renishaw’s OMV Pro software, this provides the five-axis CNC portal mill with CMM-like capability, the company says. Eliminating the need for inspection on a true CMM saves many hours of production delays, potential damage and inaccuracies that can result from moving and refixturing high-value parts. In fact, the machine-mounted probe returns results that are routinely accurate to within 0.002 inch (0.025 mm) when double-checked with other devices.

Triumph Fabrications’ core capability is stretch forming sheet, extruded, rolled shape and light plate metals for the aerospace industry. Press capacity at the climate-controlled plant ranges from 10 to 750 tons, and the company has the capability to stretch-form reverse forms using bulldozer attachments on two of its Cyril Bath presses. The company’s stretch-forming capabilities also support complex single-plane and multi-plane forming of a variety of metals.

Various types of CNC machine tools are used to produce features on these formed parts as well as to shape the forming dies themselves. These include two portal mills from Zimmerman (Novi, Michigan). Supporting this work upstream and downstream is a CAD/CAM department equipped with Catia V4 and V5, Vericut 7.0, Renishaw OMV Pro, AutoCAD, Inventor and other desktop engineering tools.

Gary Medlock, CAD/CAM department manager, says on-machine probing is essential at Triumph because parts here are typically high-value to begin with, and each operation on the Zimmerman portal mill adds additional value. “In-process measurement confirms that each phase of the work meets specifications before we put more value into the part,” he explains.

The only alternative—aside from inspecting after machining is completed and hoping no rework is required—is stopping the machining process and moving the part to a CMM. In that scenario, Mr. Medlock estimates that the company would lose nearly a day tearing down the setup, measuring the part and refixturing it for the next operation. This would also involve adding a checking groove or other feature to ensure each setup is identical to the first, further adding to costs. “These delays and the uncertainty that comes with each new setup are simply unacceptable in a lean operation,” he says, adding that most on-machine probing cycles at Triumph typically take only about as long as a machining cycle.

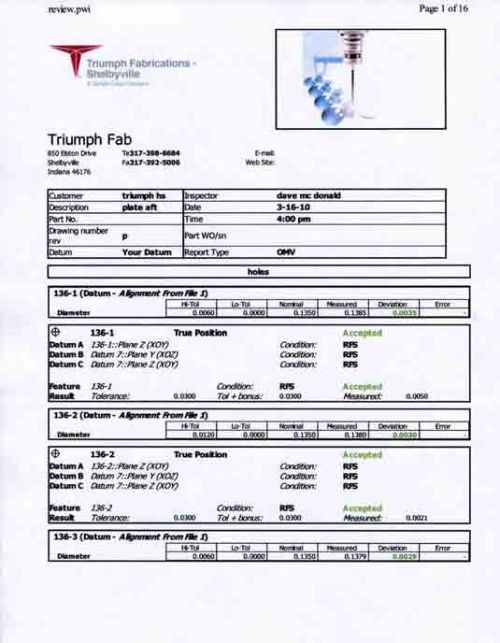

Most parts processed on the Zimmerman mill are formed sheet metal components measuring 0.025 inch (0.635 mm) to 0.125 inch (3.18 mm) thick that require machined holes and cutouts. Holes measuring between 0.098 inch (2.5 mm) and 0.375 inch (9.5 mm)—typical of aircraft applications—are drilled and reamed to accuracies of 0.002 inch (0.05 mm). True position tolerances range from 0.012 inch (0.30 mm) to 0.028 inch (0.71 mm).

Size and true position are measured via the RMP600 probe with a 0.039-inch (1-mm) tungsten or stainless steel stylus, a 1.97-inch (50-mm) extension and the two-touch probing method. “We prefer the tungsten ball for the ability to reach deep into a hole,” Mr. Medlock explains. “If you are careful about orientation, you can measure just about anything with this ball. The 50-mm extension causes no loss of accuracy, keeps the probe at a distance from the workpiece to minimize crash potential, and is cheaper to replace if there is a collision. We use two-touch probing because we have calibrated at the same speed we’re using in the software, so the timing and angles are all established.”

A key feature of the strain-gage RMP600 is its Rengage sensing mechanism, which avoids the lobing error that is inherent to conventional machine tool probes. If lobing error is excessive enough to impact measurement accuracy, users must compensate by calibrating the probe along each measurement vector. This requires a complex calibration cycle as well as management of numerous probe offsets.

In contrast, strain gages measure the contact force applied to the stylus and generate a trigger once the strain threshold is exceeded. This method results in lower trigger forces, less stylus bending, sub-micron repeatability, no lobing and true 3D triggering characteristics. According to the developer, this provides the RMP600 with significantly improved performance, especially on 3D surfaces that require numerous sensing directions, or during setups in which approach vectors to the workpiece might not be known. Logic inside the probe eliminates unexpected triggers resulting from shock and vibration by determining whether strains at the gages are caused by contact with the part surface or a random event.

As a result, the RMP600 does not have to be calibrated for each vector. This saves significant time in five-axis applications like those performed at Triumph. “Because of the strain gauge triggering system in this probe, we get a good reading—the same reading—no matter what direction we touch the stylus from, which is perfect in a five-axis world,” Mr. Medlock reports. “When you do five-axis work, the probe is used in some strange orientations, and the ball might be touched from any practical direction. We’ve confirmed that when we measure something with the probe, we’ll get identical readings if we have to re-measure.”

In fact, the probe’s capability is such that the company has been able to measure the true diameter of holes as small as 0.098 inch using a 1-mm stylus, Mr. Medlock says. However, he is quick to stress that in the end, the probe is only as accurate as the machine. The Zimmerman FZ-30 portal mill incorporating the RMP600 features a volumetric accuracy of 0.004 inch (0.1 mm). “For a large, well-used machine tool, this compares very well with typical CMM accuracy,” he notes.

Maintaining that volumetric accuracy through machine calibration is one key to Triumph’s success with on-machine measurement—and the source of its confidence in probing results. Barring a crash, the portal mill is calibrated once per year with a draw bar. The company also employs a small calibration sphere once per week in a routine that involves rotating the machine through a known set of angles and touching the sphere with the probe. These results are plotted on a histogram with data going back two years to help recognize any developing trends. In addition, the company probes a traceable artifact with a cone, a sphere, slots and other features common to its parts whenever there is a change to any component of its quality-control program.

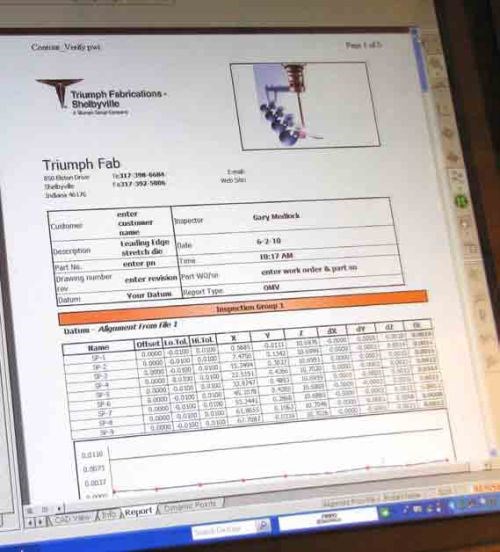

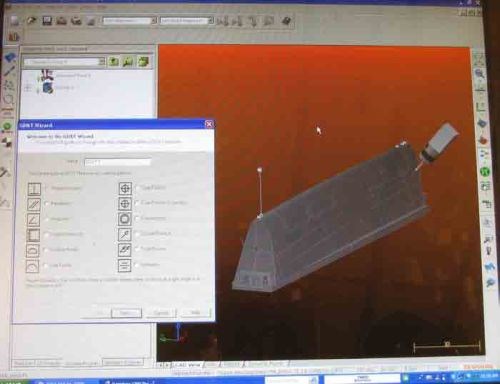

Another key factor Triumph attributes for its success is the method for programming the model and geometry. The company usually starts with a STEP file, which it imports into the OMV Pro software to create the probing program offline. The software simulates the probing routine for collision detection, and an “auto orient” function automatically orients the probe into a suitable measuring position without requiring manual input of the required angle. A number of options are available for feature measurement. For example, a hole can be measured as a circle or a cylinder.

The probing program runs on the CNC to collect the measurement data, which is then evaluated offline in OMV software with CMM-type algorithms. The software compares the measurement data with the map/model file and produces graphical and numerical reports. It then reports on the deviations from the nominal and plots a graph to show the ranges.

Finally, a GD&T wizard in the OMV software leads programmers through the process of creating standardized report elements based on internationally recognized symbols. This allows comparison of measurement results from the machine to the manufacturing drawing. The company currently uses perpendicularity, angularity, surface profile and true position, Mr. Medlock says.

“Because of the high accuracy of the portal mill and its five-axis capability, the strain-gage probe has proven to be a better match for our measurement requirements,” he concludes. “Periodic double checks against other measurement devices rarely show deviations greater than a thousandth of an inch, giving us a high level of confidence and operational efficiency.”

Related Content

4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)