Some Laser Marking Basics

The proper marking method that should be used depends on the workpiece material and the quality requirements.

Share

Manufacturing traceability is of paramount importance, especially for components used in the aerospace, automotive and medical industries. Lasers are well-suited for marking components made from metal, plastic and other materials with critical information because they offer the flexibility to perform a number of marking processes. Marking machines such as Trumpf’s TruMark series 3000, 5000 and 6000 can perform annealing, ablation and engraving (both light and deep) on metals in addition to coloring and foaming of plastics. The proper marking method that should be used depends on the workpiece material and the quality requirements.

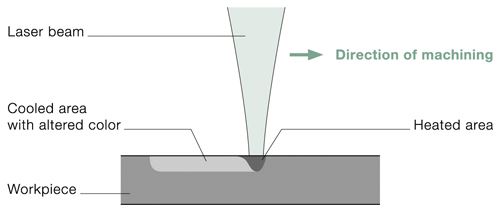

Annealing can be performed on ferrous metals and titanium. It does not remove material. Instead, annealed markings are generated using the laser beam to heat the workpiece close to the material’s melting point where the mark is to be located. The laser beam creates oxide layers on the workpiece surface. The marking color depends on the composition of the oxide as well as the temperature to which the workpiece is heated.

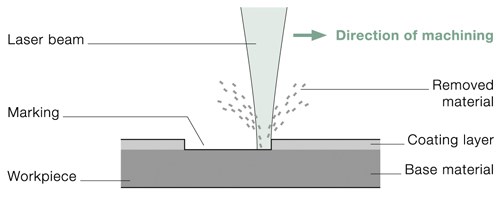

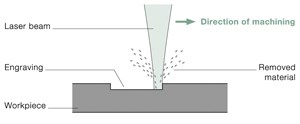

Ablation and engraving can be performed on virtually all materials, including metals, plastics and ceramics. For both processes, short, powerful laser pulses are used. The power densities are so high that the base material or coating decomposes or melts and evaporates, leaving behind the desired marking.

Ablation is the partial removal of coating layers from the base material that have a markedly different color. Typical materials for ablation include anodized aluminum, lacquer layers and special laser marking films.

Engraving is perhaps the most common laser marking process. For engraving processes, the laser beam removes material from the surface of the workpiece, leaving behind a depression. When necessary, colored oxides can be produced to further accentuate the marking. Deep engraving, which creates a more significant depression, is commonly used for molds, dies and stamping tools. The marking depth that can be achieved with deep engraving depends on how the workpiece material absorbs the laser, how much energy the laser has, and how long the laser can dwell on the target.

To color plastics, the laser beam heats the surface locally, which causes some materials to become darker and others to become lighter in color, depending on the material composition. In blackening, “soot” particles are generated to show the inscription in dark letters on light-colored plastics.

To make dark plastics white, foamed marking is used, whereby the laser beam melts the workpiece material locally. Small gas bubbles form in the molten material, which increase the material’s volume- creating foam. The processed area appears much brighter than the surrounding material and, in some cases, the marking is raised above the surface of the workpiece.

Related Content

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

-

How to Optimize Operator Efficiency on Any Shop Floor

Striking the perfect balance of person to machine is unique to each shop and can depend on a number of factors, including the type of work a shop undertakes, the available equipment, staffing levels, scheduling and more.