Solid Tool or Indexable Inserts? Why Not Both!

Kyocera SGS Precision Tools’ mill-turn demonstrations highlight varied tool choices and varied application knowledge.

Share

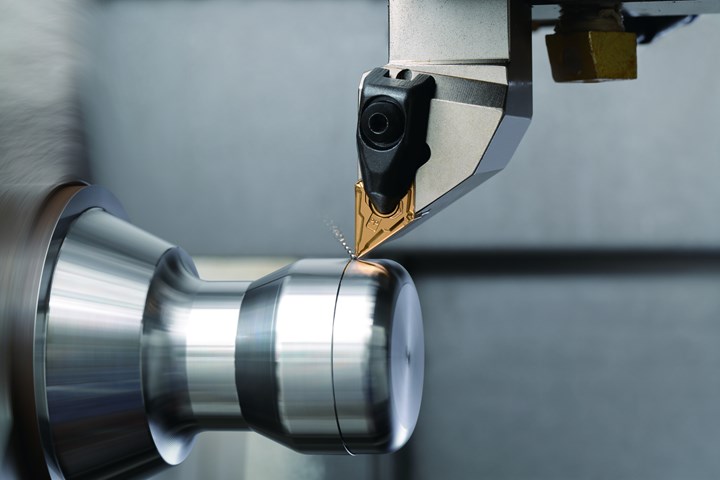

When does an application call for an indexable-insert cutting tool rather than solid carbide? With both tooling types on display in a shared space – an IMTS first for the jointly branded company – Kyocera SGS Precision Tools is likely to have the answer. In addition to standard milling and turning offerings, SGS’s solid line includes sweeping-geometry, circle-segment “barrel cutters” and coolant-through drills, while highlights of Kyocera’s indexables range from end and face mills to grooving, turning and drilling tools.

With application knowledge as broad as the jointly branded product offering, booth representatives also stand ready to show rather than tell. Live cutting demonstrations of both cutting tool types highlight where and why each stands out, while also showcasing the inherent flexibility of a mill-turn machine capable of milling and turning with both indexable or solid carbide tools.

Solid tools like the one cutting the blisk are the province of SGS, while indexable offerings like the turning tool are Kyocera’s specialty. Photo Credit: Kyocera SGS Precision Tools

Related Content

-

Chiron Group Unveils Virtual Showroom & Live Demos at IMTS 2024

Chiron Group combines the best of both worlds at IMTS 2024, featuring live demonstrations of their Micro5 and Mill 2000 machines, alongside a cutting-edge virtual showroom. This innovative approach allows visitors to explore Chiron’s full product lineup without the logistical challenges of transporting large equipment.

-

Trak Machine Tools Lathes Offer Compact, Heavy Duty Performance

IMTS 2024: The Trak TC2 and the Trak TC820si are compact lathes designed for production applications.

-

Going Hands-On with Heidenhain and Acu-Rite Solutions

Heidenhain and Acu-Rite Solutions are offering several hands-on experiences at their booth this year, as well as internal components that reduce energy use.

.jpg;maxWidth=300;quality=90)