Software Utility Helps CNC Data Management

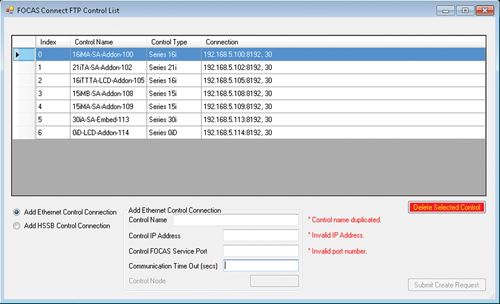

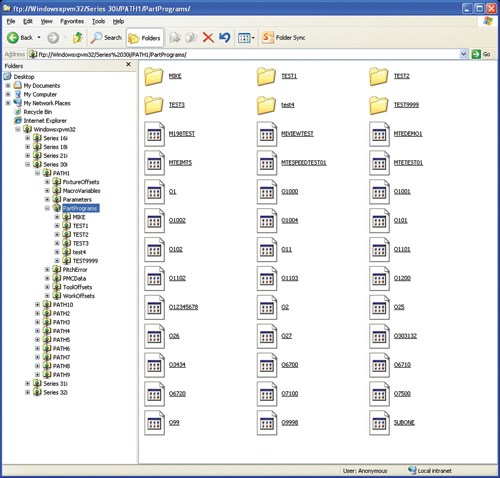

FASConnect is a software solution for network-distributed data management among machines equipped with a Fanuc CNC. It is intended to ease and simplify integration of these machines on a PC-based network for backup purposes.

Share

The computer workstations in most shops are connected to a network. This network enables users to share email messages, run applications remotely, download data and save files on a centralized server. Saving files as a backup is an especially important function of a network because it protects critical data that might be lost if one of the computer’s hard drive crashes or malfunctions. Typically, a shop’s CNC machine tools are connected to a network also, although doing so is often difficult. For this reason, shops often have a harder time backing up critical CNC data. For example, shops may have to resort to carrying portable memory devices to each machine tool to back up the files.

The system is scalable, that is, a shop or plant simply acquires new licenses to cover added CNC connections. Ultimately, as many as 22 users can be logged on at one time, with no limit on the number of machine connections. Multiple servers are also possible. According to the company, this flexibility makes the utility functional for small shops with a few machines as well as for big plants with hundreds of machines. Although only machines with Fanuc CNCs can be connected, the control units can be any model that is capable of Ethernet communication. Older units can be connected if they are interfaced to a dedicated PC using a Fanuc HSSB fiber-optic communication link to the network. The software uses the common File Transfer Protocol (FTP) for a high degree of compatibility, the company says.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)