Software Speeds ISO Certification, Improves Shop Communication

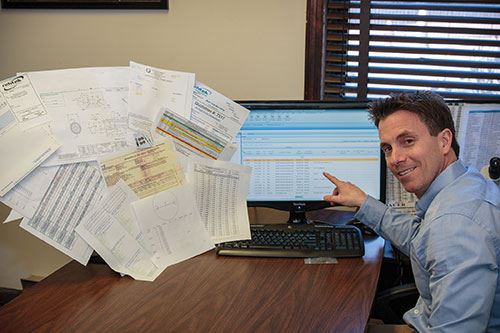

Shoptech’s E2 job shop system helped Rehtek gain ISO certification while improving quality and communication throughout the facility.

Share

When Rehtek Machine Co. owners Stephen and Paul Reh began searching for a total software solution for their machine shop, they initially set out to meet ISO 9001 quality certification requirements. However, the ISO quality module within the E2 job shop system from Shoptech Software (Glastonbury, Conn.) provided far more than that. “It also made us look at our processes and helped us put in place a quality management system that’s now part of our culture,” says Stephen, who founded the company with his brother, Paul, in 1990.

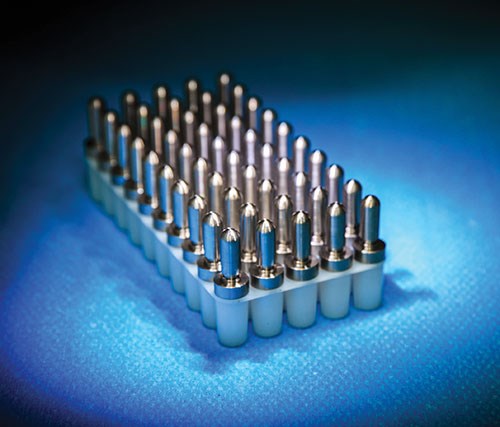

Quality is particularly important for a company like Rehtek. The 12-person job shop located in Passaic, N.J., supplies the aerospace, electronics and medical industries, and more than half of the business is dedicated to precisely machining small components for pressure sensors that control and monitor fluids and gasses. Pressure sensor parts include high-voltage contacts, connector pins, electrodes, feed-through assemblies, glass metal headers and a variety of hermetic seal components.

Most of the parts machined at Rehtek range from 0.010 to 1.5 inches in diameter, with tolerances of ±0.0002 inch and cross-drilled features starting at 0.008 inch in diameter. The pressure sensor components are machined from a variety of glass-to-metal sealing alloys, including stainless steel, Kovar, 52 alloy, titanium, Inconel and exotic alloys. These components have stringent end-user demands on finish, edges and concentricity because they need to function in extreme environments that are subject to very high pressures, low and high temperatures, and kinetic energy.

“In our business, when you’re dealing with glass-to-metal seals, quality takes on a whole new dimension,” Mr. Reh says.

For that reason, the shop was particularly attracted to the ISO quality module’s rapid documentation system (RDS) within Shoptech’s E2 software. This component automatically produces quality management system documentation, saving employees time and minimizing errors. For instance, in less than 10 seconds, employees can access any ISO quality record on the screen.

According to Mr. Reh, the RDS was embraced not only by employees, but by Rehtek’s third-party certification registrars as well, because ISO 9001:2008 quality standards are built into Shoptech’s E2 solution. The RDS component speeds ISO training and facilitates job shop compliance with ISO9001:2008, ISO13485 and AS9100 certification audits.

Perhaps the greatest benefit of E2’s ISO quality module is that it streamlines documentation. From estimates to invoicing, E2 brought all of Rehtek’s accounting functions into one module for an integrated management tool. However, before Rehtek integrated the quality module, it needed to make sure it was able to integrate with its existing reporting system. As an SAP Crystal Reports user, the company did not want to upend its legacy reporting system when implementing a new software package. As it turns out, the E2 shop system uses technology from SAP Crystal Reports, Intuit Quickbooks and Microsoft SQL Server 2012 for seamless integration into its core solution. Drawing from more than 200 report templates available in E2, Rehtek was able to customize its own reports.

On the shop floor, all internal documentation is incorporated into the job, as needed. There are no longer phantom documents on the shop floor. All documents are now traceable back to any job. The quality module covers everything from document control, non-conformances, recommended corrective actions, employee training and work center/tooling maintenance.

“E2 closes the loop for us in terms of traceability,” Mr. Reh says. “It gives us total process, document and data control.”

By using E2’s quality module, Rehtek also has greatly improved its communication with customers. For instance, external documents such as blueprints, specs, material certifications and pictures, can be easily attached at any point during the process to keep communication with the customer current and organized. Using E2 Webview, customers can view information such as quotes, tracking production, scheduling and more. This enables them to monitor job status directly over the internet.

ISO 9001 certificates of compliance are automatically generated in shipments, segmenting out multiple shipping addresses, partial shipments and back orders. E2’s auto billing ensures purchase orders, invoice numbers and packing list numbers all line up. Customers are notified of shipments automatically via email.

E2’s quality module has also improved communication within the company, thereby improving productivity and profitability. It facilitates process improvement through a documentation system that fosters contributions from employees along the entire workflow. Rehtek uses E2’s feedback and corrective action report function within the quality module to track all positive and negative aspects of a job and automatically share those reports throughout the entire company. For instance, every customer print is redlined for improvement and clarification, Mr. Reh says. It’s then attached to the router so it can be noted when the company makes that part again.

Everyone from the estimator and machine operator to the accountant has clear insights into making the process better, Mr. Reh says, and when the company makes an improvement on the shop floor, it’s documented and used going forward.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)