Small Engine Precision Fuels Fifth-Axis Production Concept

The challenge holding tight tolerances for its billet RC helicopter engine components drove this company to develop an innovative fifth-axis tombstone device to complete multiple parts on an HMC in one setup.

Share

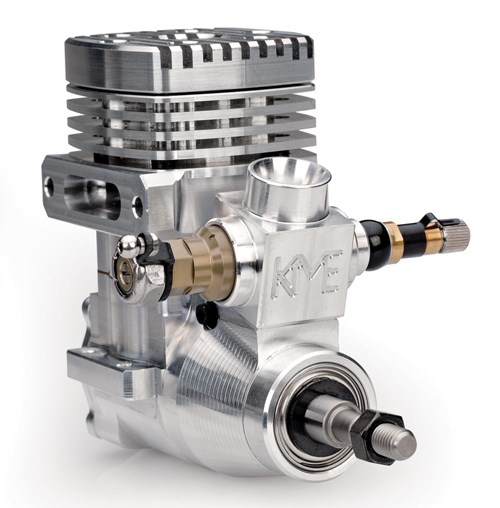

KME Engines is well known in radio-controlled (RC) helicopter circles. The Orange, California company manufactures high-end billet aluminum engines that provide the horsepower of a larger-scale engine in a smaller size. This enables owners of smaller-scale RC helicopters to realize the performance levels of bigger models, giving them 30-percent more power to perform advanced aerial acrobatics without worrying about bogging down their engines.

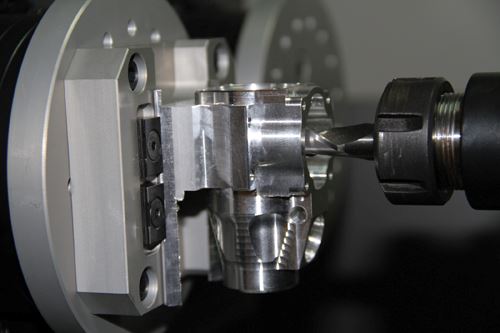

Most of the billet components used in KME’s engines must be machined to extremely tight tolerances for the engines to work effectively. For example, the crankcase has front and back crankshaft bearing races that have to be bored to within ±0.0002 inch of their respective 0.875-and 1.1-inch diameters. Plus, the nitromethane fuel that powers these engines will escape through the front of the engine if the crankcase’s center bore exceeds its nominal ID by more than 0.0005 inch. Alternately, the engine can seize if the center bore is too small because not enough oil will reach the crankshaft.

Initially, the company found it virtually impossible to hold the tolerances for crankcase bearing races on its VMC. One problem was excessive machine thermal expansion and contraction resulting from fluctuating shop temperatures throughout the day. The VMC’s axis positions could change by as much as 0.01 inch from the beginning to the end of a shift. Another problem was that each bearing race was machined in separate operations requiring two setups. The requisite feature-to-feature tolerance between the race center points was often unattainable because the crankcase couldn’t be repeatedly positioned for the next operation after the first race was machined. Machining-wise, the VMC just couldn’t pick up where it left off.

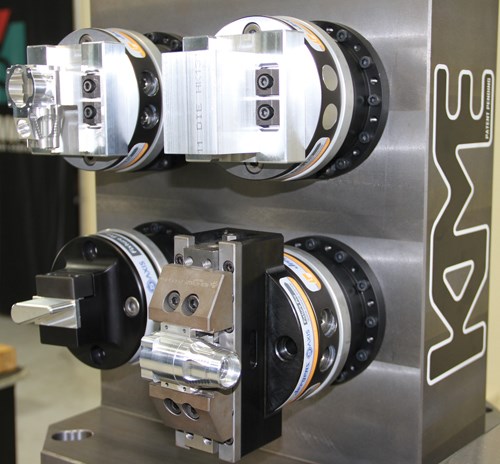

This prompted KME to experiment with alternate fixturing methods, including rotary indexers mounted atop indexing tables on its VMCs and custom jigs used on its turning centers. The company also considered installing rotary indexers on either face of a T-style tombstone for use on its four-axis HMC. This last attempt ultimately led the company to create the atypical workholding device that proved to be the answer: a T-style tombstone with integral fifth-axis rotary indexers. Each indexer is powered by its own independent servomotor installed inside the hollow tombstone. The fifth-axis tombstone enabled crankcases and other primary engine components to be completed in one setup on the shop’s more thermally stable HMC (ensuring the requisite feature-to-feature accuracies). The device also made it possible to fixture four workpieces simultaneously to realize the high production levels needed to support customer demand.

In fact, the device KME crafted to solve its own machining problem worked so well that the company recently launched a new business unit, KME CNC, to make the fifth-axis tombstone available to other shops hoping to realize similar benefits. During a recent visit, Jerome Mezzasalma and Kevin Liboon, KME’s co-owners and creators of the device, explained how their frustrating fixturing dilemma drove them to dream up an inventive five-axis HMC workholding concept.

Engine Design to Manufacturing

KME shares a facility with its parent company, K2 CNC, which manufacturers CNC routers and plasma cutters (it will soon offer waterjet machines, too). Mr. Liboon, a specialist in robotics and electronics who has owned K2 for 12 years, met Mr. Mezzasalma through their shared hobby: flying high-end RC helicopters. The two started KME in 2008 after deciding to combine their design and manufacturing talents to produce RC helicopter engines that could outperform other models currently on the market.

Prior to that, Mr. Mezzasalma designed small motorcycle engines and also set up manufacturing facilities in a number of countries. He tapped that experience in developing and refining KME’s RC helicopter engine design. Unlike most other RC helicopter engines that use cast-aluminum components, KME’s engine components are produced from aluminum billet. This is the key to achieving higher horsepower because features in billet aluminum can be produced with thinner walls. As a result, a larger bore can be squeezed into the engine’s cylinder than would be possible with a conventional cast-aluminum cylinder. Today, the company offers two RC helicopter engine versions in 0.6- and 1.1-cubic-inch sizes. The 0.6-cubic-inch engine is designed to install without modification into a helicopter that normally uses a 0.5-cubic-inch engine. Similarly, the bigger 1.1-cubic-inch engine is a direct replacement for a 0.9-cubic-inch engine.

Of the 22 components that go into each engine, the crankcase proved to be the most challenging to machine. Realizing that multiple setups would prevent them from achieving the necessary alignment tolerances for the bearing races, the men tried installing a rotary indexer to a fourth-axis table on one of their VMCs. The ability to accurately rotate the crankcase 180 degrees enabled machining each race in turn without refixturing. However, thermal fluctuations in the shop prevented the VMC from repeatedly holding the necessary tolerances. This prompted the men to try a jig produced by EDMing a profile of the crankcase into a piece of barstock. With a crankcase installed inside, the jig was clamped in a lathe that turned one of the bearing races. Upon completion, the jig was simply flipped and re-clamped so the lathe could turn the other race. Again, machine instability led to a scrap rate of about 50 percent using this method, even though the jig offered an effective way to maintain bearing race alignment on the lathe.

The men then decided to invest in additional tooling to machine the crankcases on their more stable Kiwa KH-45 HMC. A T-style tombstone with rotary indexers mounted on either face would enable producing two parts per setup. Plans changed, however, when the men realized they could capitalize on the tombstone’s hollow design by installing servomotors inside the tombstone to power individual rotary indexers.

Their fifth-axis tombstone design offers a number of advantages. The indexers extend only a couple inches from the face of the tombstone, taking up less space within the HMC’s work zone than a surface-mounted indexer. Plus, the servomotors, circuit boards and all power and signal cables are safely housed within the tombstone. A mercury swivel switch installed in the base of the tombstone pallet enables full table rotation with no cable binding. The switch engages with a mating connector on the HMC each time the pallet is rotated and lowered onto the machine’s table. Wiring for that connector travels underneath the HMC’s way covers to the tombstone’s control unit. Once a new pallet is lowered onto the table, a signal is sent to the control unit that tells the machine’s CNC that the tombstone is in position. It also signals the CNC as to what program to run.

KME machines three primary RC helicopter engine components—crankcase, cylinder and head—using the fifth-axis tombstone. Rather than kitting these components, the shop machines each component in batches of four. That way, only one part program is called up for each job. It is possible, however, for each rotary indexer to have its own part program so different parts can be set up on the tombstone at once. (The device’s control unit can hold as many as 100 part programs.)

The company has been refining its five-axis tombstone design for the last two years. The HMC’s thermal stability combined with the capability to accurately rotate the fourth-axis pallet and fifth-axis tombstone indexers has enabled the shop to meet its goal of producing 300 engines per month without experiencing the high scrap rates characteristic of previous methods.

Realizing that other shops could benefit from fifth-axis tombstone fixturing, KME is now marketing its device. Approaching each application as a turn-key project, KME works with shops to determine the appropriate number and size of rotary indexers (the device can accommodate as many as eight) as well as what other features might be required to tailor the device to a specific application.

The tombstones are constructed from rigid Meehanite cast iron. The standard servomotors provide 470 foot-pounds of torque, which Mr. Mezzasalma says is more than sufficient for aluminum workpieces. Optional 790-foot-pound servomotors are also available to facilitate the cutting of tougher materials. The servomotors have rotational resolution of 0.001 degree and offer accuracy and repeatability of 10 and 20 arc seconds, respectively.

Mr. Mezzasalma says the device with patents pending is well-suited for jobs that normally would require three or more setups. Small parts less than 7 inches wide are ideal, but it is possible to install virtually any size of servomotor into a tombstone to fixture larger parts, as well. Currently, the device enables positioning in five axes, but the company plans to offer full-five-axis contouring versions, too.

Learn about Jergens Inc.

Related Content

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More