With higher performance required from turbochargers, steering knuckles, gears, fuel systems and valves, honing is being used more widely. It can make an already “good” bore into one that is round and straight to a fine degree of precision, with high process capability and accuracy measured in tenths of a micron. However, with two principal honing processes available—single-pass and conventional multi-stroke—it’s important to match the capabilities of each to the application requirements.

Different Processes

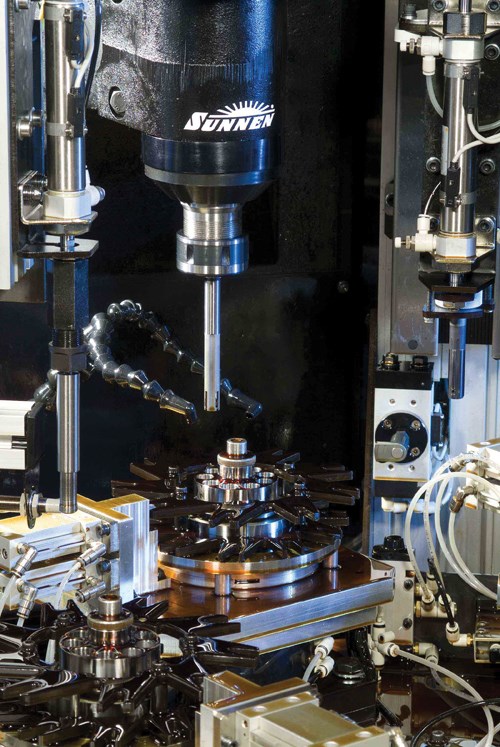

Multi-stroke honing is the more flexible and capable process because it uses “smart” tooling under servo control. The reciprocating abrasive tool with expanding stone assemblies can be controlled in size with accuracy of 0.000001 inch. Feed force of the abrasive can also be servo controlled. With the exception of diamond plated tools, the abrasives used in multi-stroke honing are self-dressing. A multi-stroke tool can be custom designed with different abrasive lengths and widths to handle blind, ported bores or landed bores. Finally, multi-stroke honing produces a pronounced and uniform crosshatch pattern on the bore surface that can be finely controlled to produce consistent, specific surface parameters that affect part wear, lubrication, lifespan, noise and more.

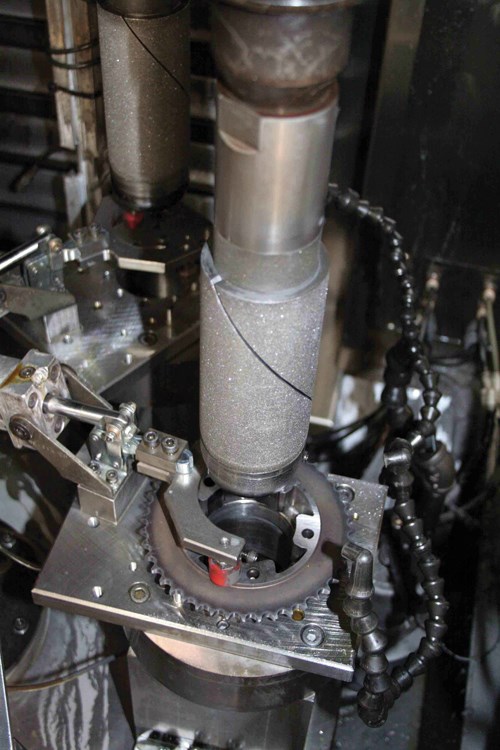

Single-pass honing machines use a series of progressively larger diamond mandrels with a fixed diameter and grit size. The abrasives are not self-dressing. Single-pass honing tools rotate while making one stroke in and out of the bore, though servo-controlled stroking provides some flexibility with adjustable speed and various feed profiles, such as pecking, short stroke and dwell. Single-pass honing is limited in the part configurations and materials it can process. Parts with L/D ratios up to 1:1 are ideal. Single-pass bore sizing also works with splined bores or longer L/D ratios if cross holes or other bore interruptions allow chip flushing. The process can mimic, but not duplicate, the crosshatch pattern produced by multi-stroke honing—a critical difference for some parts. With diameters below 0.300 inch, tool strength becomes a limitation.

Whether to use a single-stroke or multi-stroke honing process can sometimes be a clear-cut choice. For example, a blind bore, unless there is a large clearance at the bottom, always requires a multi-stroke process. In other situations, various factors affect the decision, including:

Part Materials

Multi-stroke honing works with almost any material, including the hardest steels, alnico, zinc, carbide, ceramic and plastics. With controllable cutting action, it can better control chip size, even for stringy chips.

Single-pass honing is fine for cast iron, powder metals, ceramic, glass, graphite and other free-cutting materials, but does not work well with extremely hard or soft materials. In general, materials that produce a long, stringy chip will not work well with single-pass honing.

Straightness Correction

Multi-stroke honing can straighten a bore with camber error (banana shape), particularly for parts with an L/D greater than 1:1. The abrasive is often sized to bridge the camber in the workpiece to machine it out.

In a part with camber, the sizing land on a single-pass tool follows the bore, so the geometry error usually cannot be corrected. Special-purpose single-pass tools with much longer sizing lands also have limited success reducing camber compared to multi-stroke honing.

L/D Ratio

Multi-stroke honing can be used with most L/D ratios. Parts with short bores, such as connecting rods, can even be stacked for higher productivity.

Single-pass honing is less suitable for parts with L/D exceeding 1:1, unless the part has interruptions through which chips can be flushed.

Stock Removal

A multi-stroke honing tool, depending on its size and design, can be adjusted over a large diameter range. For example, a 6-inch tool may have a half-inch range of expansion. This is the theoretical removal potential of the tool. In some applications, such as oilfield equipment, stock removal of several inches is common.

The chip clearance between the surfaces of the tool’s abrasive bond and the workpiece determines stock removal rates for single-pass honing, which is then limited by the degree of taper used on the diamond mandrel, typically from 0.001 to 0.005 inches. Stock removal also depends on the part’s material, hardness and geometry.

Surface Texture

Lubricant retention on the part’s bore surface is critical for many applications. When surface finish parameters must be reproduced accurately, along with a specific crosshatch angle, multi-stroke honing is the only choice.

The majority of the cutting in single-pass honing occurs on the down stroke. This produces a helical bore texture with little change to the surface on the upstroke, even with final reciprocation of the tool. This helical surface is unacceptable in many applications.

Surface Finish

If either process looks suitable but the parts need a consistent surface finish over the life of the abrasives, single-pass honing will be unsuitable because the abrasives are not self-dressing. With few exceptions, multi-pass honing uses self-dressing abrasives, so fresh, sharp grit is always being exposed.

Single-pass diamond tools produce a larger burr, because as the diamond grit dulls, final surface finish changes over time. The surface finish tends to become smoother as the grit dulls. The single-pass tool will also require much more power and torque to cut as it wears, similar to a worn drill bit or reamer.

About the Author: Dennis Westhoff is global business development manager with honing systems and tooling provider

Sunnen Products.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)