Simulation Software Saves Time, Boosts Confidence

Vericut simulation software from CGTech provides the confidence the company needs to machine high-value parts without the time required for manual prove-outs or the risks associated with less-robust alternatives.

Share

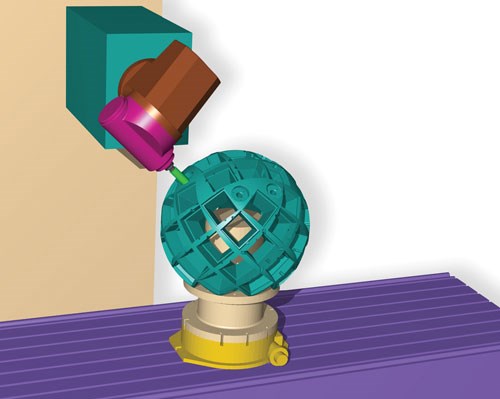

The large, spherical part in the picture below might look like a daunting machining project, but for Keller Technology, this sort of work is common—high-value, custom jobs that typically involve low production quantities, complex geometries, no room for error and no second chances. For jobs like this, proving out machining processes before tools meet metal is critical, although that doesn’t diminish the importance of timely deliveries. Steve Ziff, CAD/CAM manufacturing engineer, says one particular system is critical to meeting both of these potentially conflicting goals: Vericut simulation software from CGTech (Irvine, California). Since installation a few years ago, the software has eliminated the need for time-consuming manual prove-outs, improved confidence on the shop floor and enabled faster setups.

little more than 1 meter in diameter and weighing more than 3,000 pounds. Machined on an SL 100 five-axis machine from Parpas America (Bloomfield Hills, Michigan), the part required removing more than a ton of material to bring it to its final weight to 610 pounds. Like much of Keller Technology’s work, the part was a one-off requiring high precision, custom tooling and relatively lengthy machining routines, and it had to be done right the first time—welding to fix any gouges was not an option.

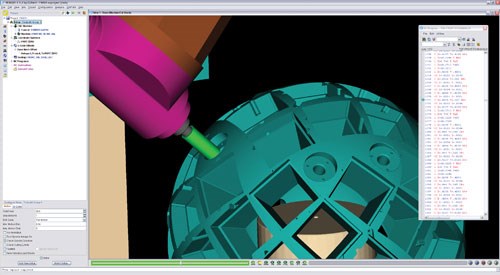

problem, Mr. Ziff ex-plains, is that the shop’s CAM-integrated verification capability is limited to checking only the internal CAM file. As a result, the system evaluates only the cutting tool’s interaction with the part without accounting for other factors that affect the process. “In the real world, you’ve got a lot more things to worry about—doors, clamps, angle plates, how the part fits on the table,” Mr. Ziff explains. “There was no representation of the full machining environment.”

the context for simulations that run from the same post-processed G code used by machine tool controls. As opposed to CAM-integrated systems that are limited to only the internal CAM file, this ensures a more comprehensive rendering of how the process will proceed on the shop floor. “What Vericut does differently is that it puts the code itself in the driver’s seat,” Mr. Ziff says.

Related Content

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)