Share

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

As robotic automation becomes simpler to implement, it is growing in popularity among job shops. This is due, in large part, to the development of methods of robot operation such as hand guiding, which don’t require large amounts of time and knowledge to use. “It’s less intimidating and easier to use, so it doesn’t require an advanced programmer to teach it,” explains Geoff Dawson, sales director at FANUC.

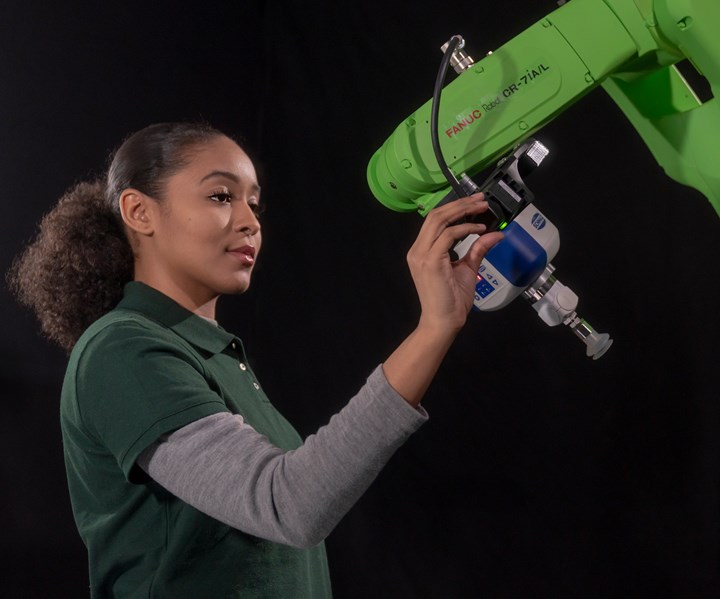

Hand guidance is designed to be a fast and simple way for operators to program and use robots. FANUC’s traditional industrial robots and cobots, like the one pictured here, can be configured for hand guidance with the addition of a joystick or handle. Images provided by FANUC.

What Is Hand Guiding?

Hand guiding is a method of collaborative robot operation. “Basically, hand guidance is a safe way of taking control of the robot to either move it as part of the process or as a teaching aid,” Mr. Dawson says. It can refer to two things:

- A method of programming the robot. Users can program robots with hand guidance by using point-based teaching or path-based teaching. Point-based teaching is when the user takes the robot to a series of specific locations, which are recorded and strung together into a path. “It’s more intuitive and easier to use for people who haven’t programmed before,” Mr. Dawson says. In path-based teaching, the user programs the robot by teaching it the entire route it must travel, as opposed to just teaching specific points. This is more useful for applications like welding, sanding or polishing, where the entire path of the robot’s motion matters.

- Taking control of a robot by hand and positioning it within a process. For example, if a part is difficult for a robot to pick up because it has a complex or irregular geometry, the operator can step in and hand-guide the robot into position so it can grab the part. This method can be combined with traditional programming. Mr. Dawson gives the example of a robot working automatically in one area that moves to another area that’s protected with either safety scanners or a light curtain. The operator can hand-guide the robot in the protected area where safety shutoffs would otherwise prevent it from running unattended, then move the robot back to the first area where it resumes operating automatically.

This method of operation has been around for years, Mr. Dawson says, particularly in painting applications. But the technology has advanced within the past decade after hand guidance was described as a safe method of collaborative operation in the RIA 15.06-2012 safety standards.

A number of robot types can be configured for hand guidance. FANUC’s entire line of collaborative robots support hand-guiding equipment. Mr. Dawson says all of the FANUC cobot models use a joystick, while the larger models (such as the CR-35) can also use a handle with an emergency stop and an enabling device.

The company also has a new line of collaborative robots, the CRX family, which have built-in hand guidance (officially called Manual Guided Teaching). The CRX cobots are purpose-built for collaborative applications, according to Mr. Dawson. In addition to the built-in hand guidance, users also have the option to program the robot with a conversational interface that has drag-and-drop actions.

Hand-guidance can also work with traditional industrial robots. “Most of our FANUC robots can be made to work collaboratively using the handle that has the e-stop and the enabling device on it,” Mr. Dawson says. Because hand-guiding is a collaborative application, using a traditional industrial robot requires additional safety measures, such as speed and separation monitors, vision systems and/or light curtains.

Mr. Dawson says that safety concerns for hand-guided robots are the same as they are for any collaborative application. “The robots are safe, the hand guidance can be safe, then you start looking at your application: your grippers, the parts you’re handling, the process you’re taking it through,” he says. Basically, because hand-guided robots are collaborative, they already have safety measures in place, but these measures don’t cover the parts, the grippers, other peripheral equipment and the path.

Hand-guided robots, such as this FANUC CRX with built-in hand guidance (Manual Guided Teaching), can be set up in less than an hour and can be redeployed in as little as a few minutes, according to Geoff Dawson, sales director at FANUC. This makes them ideal for high-mix, low-volume environments like job shops.

Hand Guiding in a Job Shop

Mr. Dawson says that most applications for hand-guided robots in job shops will involve programming, and not necessarily taking control of a robot during a process. Hand-guided programming enables users to quickly and easily reprogram the robot to handle new parts, machines and production processes, an obvious benefit in a high-mix, low-volume environment like a job shop. For this programming, “We’re not talking about hours and days — we’re talking about less than an hour, less than a half hour,” Mr. Dawson says. From there, for relatively simple adjustments, such as changing the size of the part the robot is handling, redeployment could be a matter of minutes. These changes don’t require advanced knowledge of robot programming.

“We’re not talking about hours and days — we’re talking about less than an hour, less than a half hour.”

Within a job shop, machine tending is one of the most common applications for robots programmed with hand guidance. Mr. Dawson described a different role, a welding application, in which the user programs a long weld path for a robot, which can then run while the operator sets up another robot in another cell to do the same thing. This concept could be applied to machine tending if a shop runs small batches of parts. “It’s a quick setup tool to allow an operator to run multiple stations,” he explains.

Hand-guided robots can also be useful for secondary operations, like deburring. Inspection is another good application for hand-guided robots in a job shop. Operators can use hand guidance to teach datums as part of an inspection process, or the robot could pick up a part and the user could roll the wrist around using in-process hand guidance to look at all sides of a part during a visual inspection. “As opposed to visually inspecting in many cases, you get more consistency because you’re inspecting the same way every time, walking through the same set of paths,” Mr. Dawson notes.

Because applications with hand-guided robots are collaborative, they have some limitations. Cobots are usually weight limited, and Mr. Dawson says most applications are below 15 kilograms. But the biggest limitation is speed. “When you’re hand guiding, you’re not at full speed,” he says. “You’re at safe speeds, or collaborative speeds.” However, it’s worth noting that these disadvantages are due to the collaborative nature of the applications, and not specifically due to limitations of the robot and hand guidance.

Technology is advancing to address some of these limitations. Even now, hand guidance can be applied to larger robots, enabling operators to move parts weighing as much as 700 kilograms. Mr. Dawson predicts that hand-guided robots will eventually be able to handle even more applications at higher payloads. He also believes that stopping mechanisms and safety vision systems will improve, increasing collaboration between humans and robots. “I think we’re going to continue to see this area grow, as far as not just hand-guiding, and not just power- and force-limited robots, but the overall steps in technology that allow us to have more operator collaboration with robots of various types,” he says. “I think we’re just scraping the surface of this.”

Related Content

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreRead Next

What Makes Smart Robots Smart?

How manufacturing technology “thinks,” and the extent to which it should, are critical considerations in applying artificial intelligence intelligently.

Read MoreAutonomous Bin Picking for CNC Machining Applications

With the launch of a new application kit for collaborative robots, Universal Robots is creating a new option for lights-out machining. But the company may have tapped into a solution for a deeper problem: attracting millennials to the manufacturing workforce.

Read MoreMachine-Tending Automation Gets a Head Start

Making industrial robots more versatile without sacrificing speed or power stretches integration investments and attracts new business.

Read More

.jpg;maxWidth=300;quality=90)