Moving from screw machine production house to customer-centric contract shop is no easy road to travel, but Nolte Precise Manufacturing had a plan in place for a smooth ride. As the company transitioned during the past decade, it steadily expanded its use of E2, the shop management software purchased in the late ‘90s from Shoptech Software (Glastonbury, Connecticut). According to Doug Coster, Nolte’s owner and president, the result has been deeper insight into the intricacies of the shop’s own operations—insight that has helped root out inefficiencies, streamline processes, improve communication among disparate departments, and boost flexibility, among other advantages.

Based in Cincinnati, Ohio, the fourth-generation, family-owned company got its start in 1916. Founder Louis Nolte—Mr. Coster’s great-grandfather—named his fledgling shop Nolte Screw Machine to reflect its focus on the type of small, high-volume work typically associated with that equipment. In 2002, however, pressure from low-cost overseas competition spurred Mr. Coster and his father, third-generation owner Bob Coster, to attract a more diverse customer base. The next few years saw the addition of new turning, milling and Swiss-type equipment as well as prototyping, engineering support and inventory management services. The father-son team also changed the name to Nolte Precise Manufacturing to ensure outside perceptions matched the new reality. Today, the shop produces precision components for industries ranging from aerospace and automotive to hydraulics, pneumatics and firearms, and no single sector accounts for more than 10 to 15 percent of its total business.

However, ensuring a successful transition required more than the investment and learning curve associated with adding new equipment, says the younger Mr. Coster, who became company president in 2009 and owner in 2011, the year his father retired. Machines and expertise don’t help with efficient work scheduling, for example—especially for rush jobs and parts produced on a just-in-time basis according to customers’ inventory requirements. Nor do they aid in accurately quoting jobs, following recommended maintenance schedules, properly documenting processes and procedures, replenishing supplies as needed, and so on. Yet for a shop that thrives on diversity, it could be argued that such concerns are nearly as important as having the right machining capabilities.

That’s certainly true for Nolte, Mr. Coster says, and it accounts for why the company has come to rely so heavily on its E2 software. Today, the shop uses all available modules, from quoting and order entry to shipping and accounting. The changes over the years have been both numerous and significant, but those Mr. Coster cites as most important fall under three broad categories:

• Streamlined Processes. Since purchasing E2 in 1997, Nolte has been using the system to create work orders that incorporate part routings, material lists, operation sequences and other such information into one, easy-to-access job packet. However, this functionality could never be truly efficient when used in isolation. Prior to expanding its use of E2, the shop used an entirely different system to estimate cycle times, production costs and other data needed to create quotes. As a result, moving a job from quote to order required recreating the whole data set from scratch in E2. In addition to occupying valuable time, this duplicate data entry often resulted in confusion and inaccuracies when estimates didn’t jibe with the day-to-day realities of the shop floor.

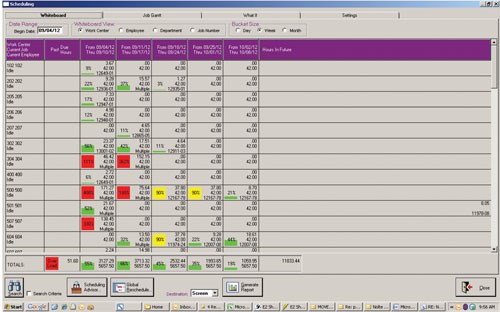

Today, the shop uses E2 for both estimates and orders. Operating from the same data set saves time and ensures that all data is both accurate and up-to-date, Mr. Coster says. Now, when an order comes in, the production manager has immediate access to all information needed for job scheduling, a function also handled within E2. To save time, the shop has configured the software to keep accurate counts of all finished parts. When quantities of certain components reach a predetermined threshold, E2 helps alert operators that more are required. Management can then use the software’s whiteboard system—which provides a real-time picture of what is happening at each workstation—to schedule the parts accordingly.

This capability is especially important given the nature of Nolte’s work, much of which is supplied on an as-needed basis, as opposed to specific batch sizes. Moreover, many of these jobs involve multiple subassemblies and tight-tolerance components, some of which are produced in-house and some of which are produced wholly or partially by outside vendors. Without E2, the resulting complexity would be overwhelming, Mr. Coster says. “We used to spend hours counting product and trying to make decisions on what to run,” he recalls.

• Improved Communication. “It wasn’t all that long ago that you might not be able to ask an operator ‘What is the next job you’re supposed to run?’ or ‘How far along are you in your current job?’” Mr. Coster says. “Today, all of our employees can answer these questions immediately. ”

A major reason for that is E2’s whiteboard scheduling system. Relevant data for all jobs is readily available at kiosks scattered throughout the shop floor. For shopfloor personnel, this clarifies all responsibilities: due dates, production sequences, materials needed and so on. Keeping everyone on the same page also goes beyond the shop floor. For example, the sales department can easily access backlogs, the purchasing department knows what to order and when, and the shipping department can track job progress in real-time.

This is a stark contrast to the way the shop used to operate, Mr. Coster says. In previous years, the company relied too much on “tribal knowledge.” For example, upon receipt of an order, a single person might be responsible for tracking down the quote from the original estimating system, transferring that information to E2, and scheduling the job, all according to his or her own experience and knowledge of what was happening on the shop floor. Now, the process is seamless and more open, and everyone operates from the same information. “Nobody has to go around asking a bunch of questions,” Mr. Coster says.

• Greater Foresight. The changes detailed above represent only a portion of the improvements Nolte has realized from expanding its use of E2. However, Mr. Coster says the most important improvement of all is the cumulative effect of these changes: a deep level of business insight that has improved planning and accountability.

For example, management can experiment within the whiteboard scheduling system to determine how a given job might affect the rest of the operation before committing. This is especially useful for jobs involving multiple sub-components as well as higher-volume runs of complex parts that occupy valuable workstations for long periods of time, Mr. Coster says. This feature, as well as ready access to data, also makes it easier to build what he calls “hero time” into the production schedule. That is, Nolte leaves time open to accommodate rush jobs or unforeseen circumstances.

One way this is done is by generating custom reports that can show activity on specific workstations during specific time periods. Organizing information in this way would have been much more difficult with previous, manual methods in-volving spreadsheets and printouts, Mr. Coster says. The case is similar with maintenance, training and quality reports. For example, determining maintenance costs per machine is relatively easy. Additionally, the software issues alerts when equipment is due for maintenance. This helps keep the shop on schedule and accountable.

Mr. Coster says Nolte will likely continue to expand its use of E2. “I have no problem recommending E2 to any size shop. You can implement it in 90 days, and it is flexible enough to work with how you run your business.”

.jpg;maxWidth=300;quality=90)