Seen in a Sidebar

Although one of my recent stories focused on peel grinding, it also included a sidebar about an alternate through-coolant grinding wheel dresser. READ MORE

Share

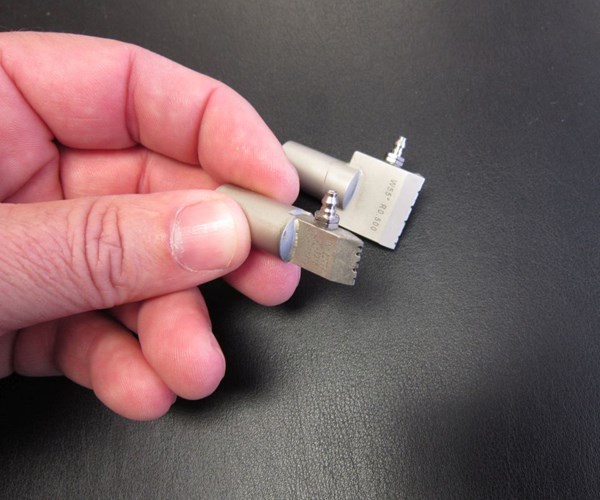

Complete Grinding Solutions often uses CVD dressing plates with internal coolant passages for more effective dressing of its grinding wheels.

Sometimes feature articles in Modern Machine Shop include short sidebars. These sidebars sometimes present information that isn’t directly related to the primary focus of the article.

An example is found in this story, which explains how Complete Grinding Solutions in Ohio leverages a high-speed peel-grinding process that resembles turning to effectively grind challenging materials such as carbide.

During my visit, I learned that Complete Grinding Solutions often uses CVD diamond dressing plates with internal coolant delivery like the ones shown above from Switzerland’s Diamant Weber. (The shop also sells these and other diamond dressing tools as a distributor for Diamant Weber.) Delivering coolant through the plate enables it to more effectively reach the diamond contact points during the dressing operation (although these are not used to dress the metal bond wheels used for peel grinding). The shop started using these through-coolant dressing plates a few years ago for a high-production job grinding automotive power steering input shafts. The conventional dressing plates needed to be replaced every two to three weeks, but the through-coolant plates lasted six months.

So when you see a sidebar in a story, don’t skip it. You might miss out on a neat machining tidbit.

Related Content

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

-

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.