Reuniting Manufacturing and Design for Effective AM

Designing the build is just as important as designing the part.

Share

Takumi USA

Featured Content

View More

As a machining professional or manufacturing expert, how many times do product designers or engineers tell you how to make a part? I am guessing rarely, if at all, just like you do not tell them how to design or engineer their parts.

Instead, they specify geometric dimensions and tolerances for each component that they want you to manufacture, and then you tell them the best way to make it to meet those specifications. Once they realize how expensive the components are to make with the current specifications, they tweak the tolerances and iterate until both parties reach a compromise.

With additive manufacturing (AM), specifying how the part will be built is just as important as designing the part itself. So, when engineers are designing new parts to be made with AM, they have to think just as much about build orientation and layout as they do the geometry and features being designed into their parts, otherwise, they may not get the part they designed.

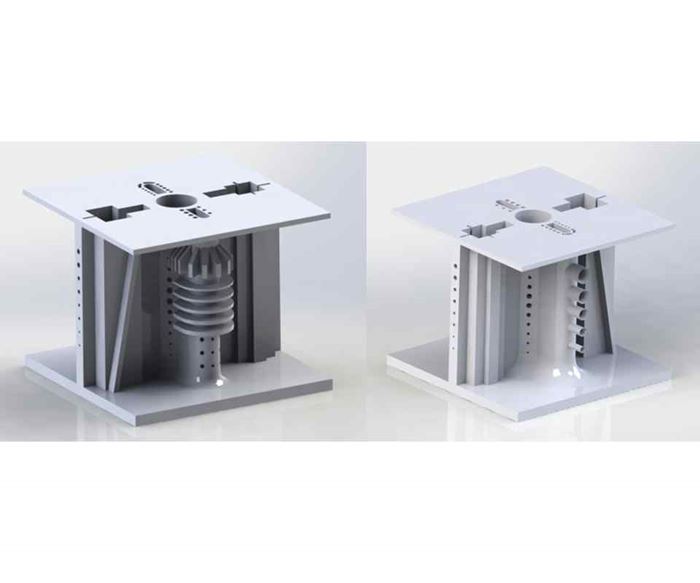

Consider the test part in Figure 1, which was designed by Andrew Coward, a Ph.D. student working with Dr. Karen Thole at Penn State to evaluate AM for gas-turbine applications. The test part was designed with features that are typical of these applications: small, internal piping; orifices; protrusions; thin walls; fins and more that are oriented in different directions.

The 3D solid model was sent to three AM service bureaus that were asked to manufacture it in a readily available metal alloy. The CAD file and material were specified, but the build process was not. Each service bureau could orient and additively manufacture the part however they wanted. This test simulated the same “hand off” that designers are used to making with traditional manufacturers.

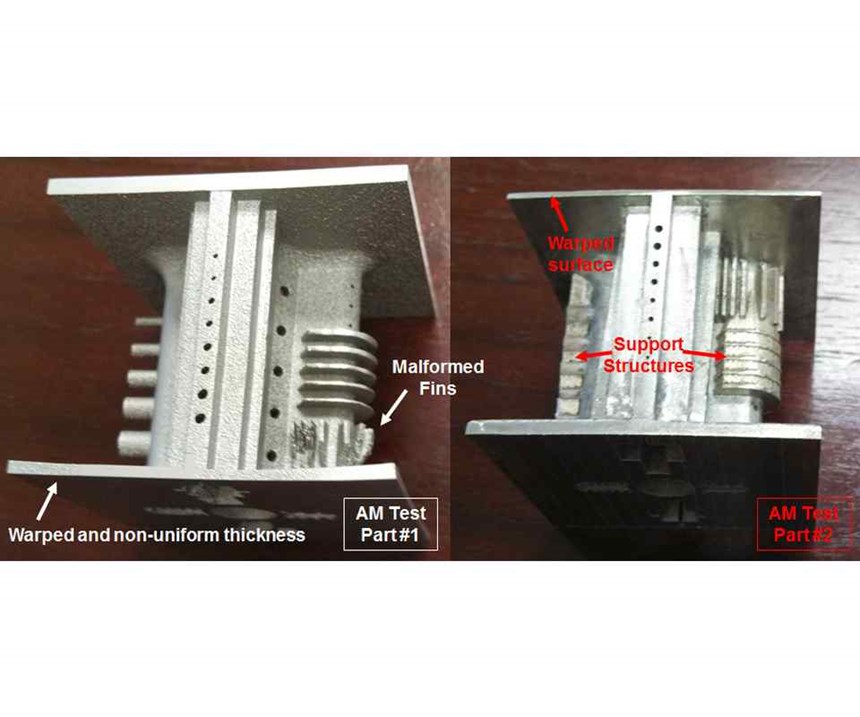

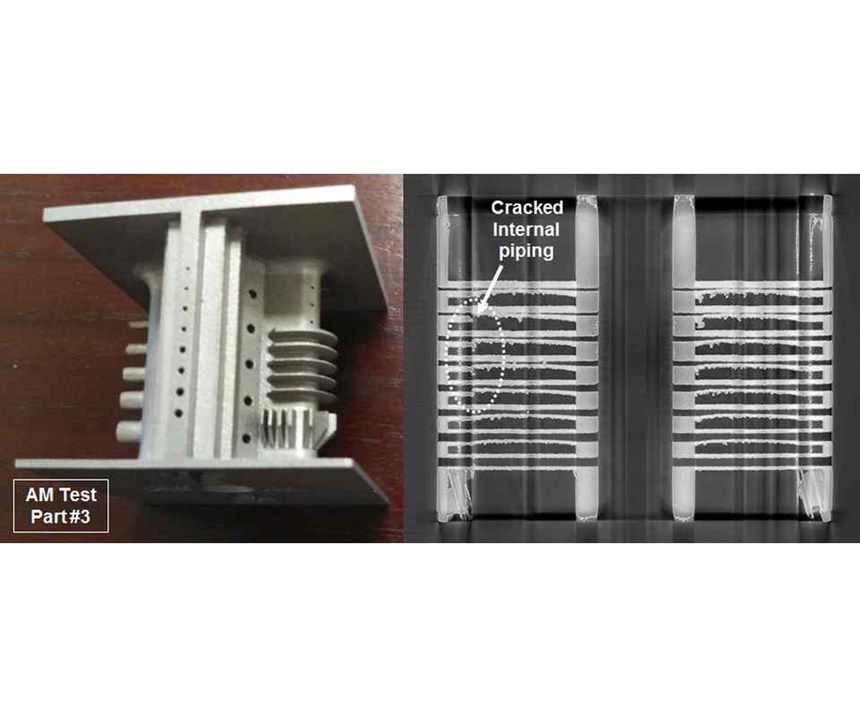

The lack of build-process specification resulted in drastically different parts. Figure 2 shows two of the AM test parts, highlighting the warped edges, non-uniform surfaces, missing fins, support structures that were not removed and other issues. Further analysis in our computed tomography (CT) scanner revealed that the part that looked the best on the outside was actually the worst on the inside (see Figure 3), while the one that looked the worst on the outside was the best on the inside.

So, what happened? Well, design was “divorced” from manufacturing in this case, and the team did not get what it designed. One service bureau oriented the part to ensure that the internal features printed well, another focused more on the external features and the third tried a compromise between the internal and external features. No matter how the part is oriented, it is very difficult to print, and everyone learned a valuable lesson.

Without specifying (designing) the build, AM producers are going to do what is best for them, which is typically reducing build time and material utilization. This often means picking an orientation that minimizes build height, which can cause all sorts of headaches when it comes to post processing and finishing (machining) AM parts.

This is not intended as a critique of AM service bureaus. Rather, it reinforces the importance of designing the part and designing the build when it comes to AM.

SPEAKING OF DESIGN

The effect of gas flow within the build chamber has a lot to do with how you orient a part. Read the story “What Effect Does Gas Flow Have in Metal Additive Manufacturing?” from sister publication Additive Manufacturing.

Related Content

6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreJTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreGo Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreRead Next

What Effect Does Gas Flow Have in Metal Additive Manufacturing?

Sintavia has partnered with one of the world’s leading providers of industrial gases in order to understand and improve metal AM’s most significant process variable.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)