Retention Pins that Both Position and Clamp

Shops and fixture manufacturers commonly use spring-loaded retention pins in their workholding devices to ease part loading.

Share

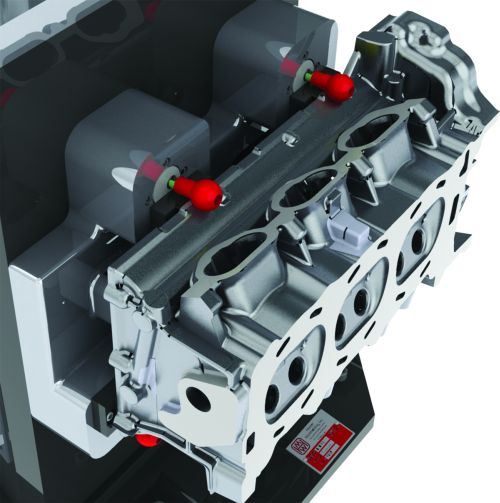

Shops and fixture manufacturers commonly use spring-loaded retention pins in their workholding devices to ease part loading. These devices help users locate a part on a fixture and hold it in place before actuating the swing or link clamps that secure the part for machining. They are especially helpful when loading parts onto an HMC, a case in which gravity works against the machine operator (although this can be an issue with loading VMCs, too).

Years ago, Master Workholding president Mike Powell came up with an alternative to conventional retention pin spring designs that were prone to failure. Mr. Powell says the downside of those designs was their use of rubber seals, which were ineffective in preventing debris from entering the mechanism. Conversely, the Position and Retention Pin (PRP) he developed uses a rotating, sealed-ball design with a tighter, more robust metal-to-metal seal. The PRP also features a threaded pivot shaft to accommodate standard as well as custom head styles users create from blanks to suit their specific application. In addition, its ball-lock mounting system enables easy installation into a fixture without special tools.

Mr. Powell explains that a customer’s recent tricky workholding application led to the development of a new PRP version. In this case, the fixture offered limited space to accommodate both the PRPs and bulky hydraulic clamps. This spurred the idea for the dual-purpose Hydraulic Position and Retention Pin (HPRP), which, like a PRP, keeps the part in place after it is loaded, but also includes a hydraulic circuit enabling the device to function as a clamp.

Master Workholding’s HPRP offers 600 pounds of side-clamping force at the maximum operating pressure of 5,000 psi. (If an application requires less clamping force, the hydraulic pressure can be reduced at the pump or with a pressure-reducing valve.) Combining the retention function with clamping capability in one device means fewer clamping elements are typically required. The design’s low profile and small footprint also help to improve part access, which is particularly helpful for getting the most out of a five-axis machine. Plus, a built-in eccentric shaft allows for adjustments to account for variations in castings.

Oftentimes for op-10 work, swing or link clamps must be used with HPRPs. However, after that work is completed, the part typically has a machined ledge and can be clamped from the sides. This means HPRPs might be all that’s required for op-20 clamping. As with any hydraulic clamping device, users calculate the machining forces for a given application to determine the required number of HPRP units. That said, Master Workholding’s custom workholding device designs direct most or all of the machining forces into hard stops rather than hydraulic clamping components whenever possible.

Related Content

-

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

.jpg;maxWidth=300;quality=90)