Replacing Manual Labor with CAD/CAM-Powered Laser Cutting

Manual box-section steel cutting took days and was inconsistent in quality. A laser machine powered by Radan software has reduced component fabrication time from days to hours.

Share

A combination of Mazak Optonics laser cutting technology and Radan CAD/CAM software slashed the time taken by Watson Gym Equipment to manufacture vital components of gym equipment from two days to half a day.

Based in the U.K., Watson Gym Equipment manufactures strength-training equipment that is shipped all over the world — almost a third of it to the United States. As shown here, box-section steel makes up vital components of the completed product assemblies.

The U.K. company supplies strength training equipment to high-end personal training gyms catering to professional and even Olympic athletes. Operating with 40 employees in a 40,000-square-foot facility, Watson ships most of its product overseas, with about 30% of it ending up in the United States. Its product range of around 200 machines are designed for anaerobic, strengthening exercises, and each machine is fabricated with sheet metal and box-section steel.

Simon Watson, managing director, stands next to the shop’s Mazak Optonics laser cutting machine: a Fabri Gear 220 II. It came pre-installed with powerful CAD/CAM software powered by Radan’s Radtube platform.

Manual Labor

The company used to work the box steel manually, taking an eight-meter-long piece, cutting it to the length required for the component, mitering it and then adding holes. While the company has used a milling machine, a flatbed laser and a couple lathes to cut other components for several years, it was seeing how much time the welders had to spend manually cutting and processing the box sections that prompted the shop to invest in a laser tube cutter. In addition to the fact that manual cutting was time-consuming, Managing Director Simon Watson says that downtime for blade changes and saw maintenance made things worse. “Also, when someone’s cutting lengths of steel 20 times, they’re not going to get all 20 to the exact same length,” he adds.

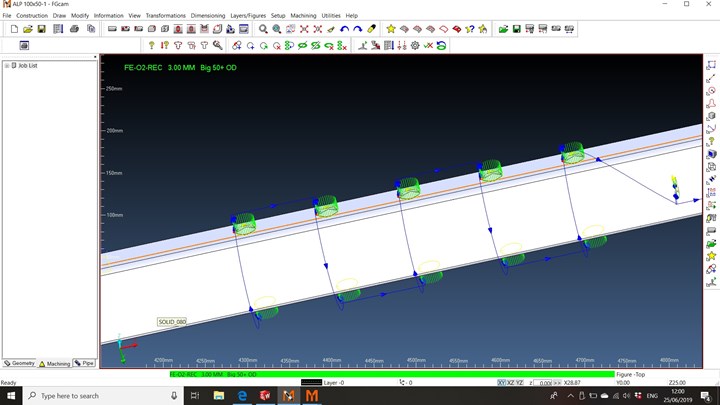

Now, the shop uses a Fabri Gear 220 II laser tube cutter from Mazak Optonics. The machine came pre-installed with FG-CAD/CAM powered by Radtube, a laser cutting CAD/CAM system by Radan. (Radan is part of Hexagon’s Manufacturing Intelligence division.) This system processes the most complex pipe and box section shapes in a fraction of the time taken by traditional methods, Mr. Watson says, adding that the machine and its cutting software have completely transformed the way the company cuts box-section steel.

FG-CAD/CAM came pre-installed on the Mazak Optonics machine. Powered by Radan’s Radtube software technology, the system has automated a lot of what Watson Gym Equipment once did manually.

Benefits of CAD/CAM Laser Cutting Software

The cutting system has provided several benefits for Watson’s fabrication process besides just time savings:

- Design for Assemblability: The system enables tabs to be created in such a style that the apparatus can only be put together one way. “We use different sized tabs and make them non-symmetrical, so when the welder comes to fit the pieces together, it’s like a jigsaw puzzle. It completely eliminates human error at the assembly stage,” Mr. Watson says. “Previously, we had to draw both the tabs and slots. But now I just click where I want the tab, input the gap around it, and it automatically inserts the slot immediately.”

- Special Programming: The software makes it easier to program a joint-strengthening scalloping-out procedure, for example. “It does everything we were doing by hand, and a lot more besides," Mr. Watson says.

- Near-Identical Components: Often, Mr. Watson has to design box-section components that are identical except for the addition of holes — primarily for the frames of the company’s weight machines. “One side may have numerous holes in it, but none in the other," he says. “Instead of having to draw it twice, I draw it once with the holes, create a mirror image, and put everything into FG-CAD/CAM and simply take out the holes.”

- Consistency: Mr. Watson has also seen improvements in laser cutting compared to the inconsistency to which manual cutting processes are prone: “The Fabri Gear and FG-CAD/CAM process makes everything consistent and uniform. This also means that if we need to replace any parts on an existing piece of apparatus we know the new part will be completely accurate.”

“We noticed massive improvements in time and accuracy right from the start,” Mr. Watson says. “And it’s so easy to use. I felt quite comfortable doing basic tasks after just one day’s training. Within a couple of weeks, I was completely comfortable doing anything.”

Related Content

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

Integrated Waterjet Expands Laser Cutting Potential

Designed for small, intricate features like turbine blade cooling holes, technology that fuses water and light virtually eliminates the traditional drawbacks of laser cutting without compromising the benefits.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More