Renishaw Practices the Pyramid it Preaches

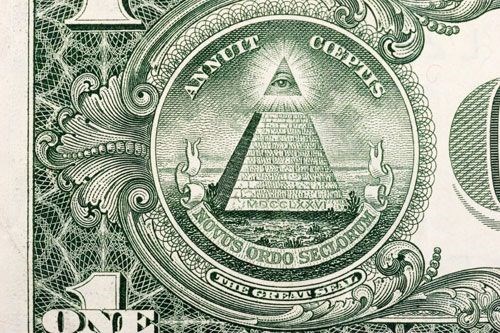

Shops can get more of these pyramids using Renishaw’s pyramid.

Share

Shops can get more of these pyramids using Renishaw’s pyramid.

I visited Renishaw’s main machining facility, Stonehouse, three years ago to see how its RAMTIC (Renishaw’s Automated Milling, Turning and Inspection Center) had been updated since MMS first wrote about it in 1999. What I saw there was one of the most advanced manufacturing facilities in the world. The original RAMTIC concepts, such as the use of portable carousels for palleted workpieces and artifacts (or master components) for machine calibration, were still very much in use. You can see my report here.

Underlying RAMTIC is a broader concept for disciplined process control. Renishaw now calls this the “Productive Process Pyramid.” The company recently released a white paper outlining this model for predictable productivity, which addresses issues faced by almost every machining operation. The key is tackling process variation at the source, isolating root causes and stabilizing them. Find this white paper here.