Reducing the Weight of a Robot Actuator

A metal additive manufacturing process reduced the weight of a hydraulic actuator, leading to a better performing component.

Share

Hwacheon Machinery America, Inc.

Featured Content

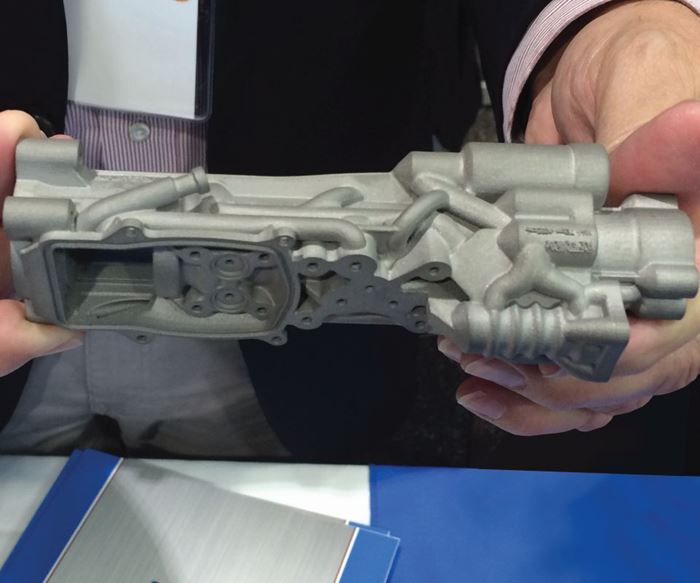

View MoreThis highly integrated electronic actuator for a hydraulic quadruped robot needed to meet design requirements while achieving a 50 percent weight reduction, compared to a traditionally manufactured actuator body.

A powder-bed metal additive manufacturing process called selective laser melting (SLM) allowed it to be made as one piece. The part was grown layer by layer in Ti6Al4V (titanium alloy) on a Renishaw AM250 industrial 3D printer at the Moog Additive Manufacturing Center (now part of Linear AMS).

The new actuator’s one-piece construction reduces manufacturing operations, improves performance through design features such as curved flow tubes that eliminate right-angle drilling, and reduces weight as a result of downsizing. Traditional manufacturing would have entailed combining the cast and fabricated pieces with brazing and welding operations.

This particular actuator is used on each leg of a quadruped robot developed at the Italian Institute of Technology in Genoa, where it was designed initially for military applications. However, a similar actuator concept can also be used in many other applications, for example: heavy equipment, such as tractors and large earth-moving equipment, for weight and size reduction; military and commercial aircraft, to control velocity and engine speed by adjusting levers and flaps; and injection-molding applications for exact precision control.

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

.jpg;maxWidth=300;quality=90)