Reducing Fastener Grinding Costs Using Advanced Abrasives

Ceramic aluminum oxide wheels can increase the number of parts that can be ground between dressing routines, leading to centerless grinding cost savings.

Share

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreReducing overall production costs in today’s globally competitive market requires identifying all contributing factors and focusing efforts on the worst offenders. For example, in the fastener industry, centerless grinding is an operation in which process improvements can yield significant benefits. Oftentimes, fastener manufacturers opt to use low-cost abrasive wheels to reduce consumable expenditures. However, according to abrasive supplier Saint-Gobain, this strategy doesn’t account for a more likely culprit behind increased centerless grinding costs: non-value-adding wheel dressing time.

Low-cost aluminum oxide wheels require frequent dressing routines to maintain workpiece tolerances, surface finishes and production levels. Conversely, ceramic aluminum oxide abrasives, such as the new Norton Quantum line of grinding wheels from Saint-Gobain, can enable fastener manufacturers to realize more significant cost reductions by increasing the number of parts that can be ground between dressing routines.

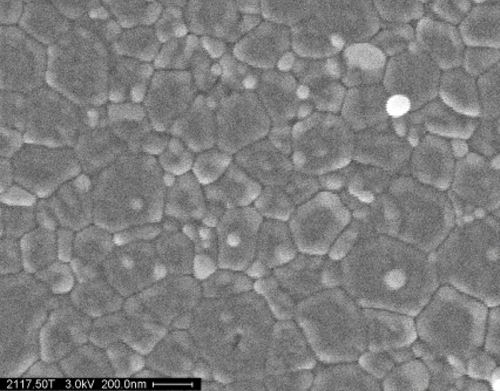

Unlike conventional aluminum oxides, the microstructure of Quantum ceramic aluminum oxide has numerous small, irregularly shaped crystals that enable the wheel to continuously expose fresh cutting points. The company says this microstructure is even finer than other ceramic aluminum oxide grades such as seeded gel, meaning more points can be introduced to the workpiece. In addition, Quantum uses organic and vitrified bonds designed to optimize grain-to-bond adhesion and increase grain retention and wheel life.

According to the company, grinding tests of nickel alloy fasteners have shown that Quantum wheels can complete three times as many parts per dressing routine than conventional aluminum oxide. This improved performance impacts the overall grinding process not just by lowering per-part abrasive costs, but also by reducing wheel dressing time by as much as two-thirds. Assuming workpiece grinding time for both types of wheels is the same, the total cycle time can be reduced by one-third.

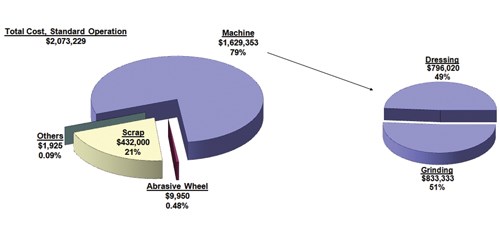

Consider a production run of 10,000,000 fasteners. According to the company, centerless grinding machine cost constitutes the largest portion of overall fastener production expense, and wheel dressing accounts for almost 50 percent of that portion. If wheels require dressing after every 60 or 70 parts, the production run will include approximately 150,000 dressing cycles. If each of these cycles takes an average of five minutes, overall dressing time will take approximately 13,000 hours. Assuming a conservative, fully burdened labor rate of $60 per hour, that amounts to a nearly $800,000 expense for non-value added dressing operation, or about 38 percent of the total production cost.

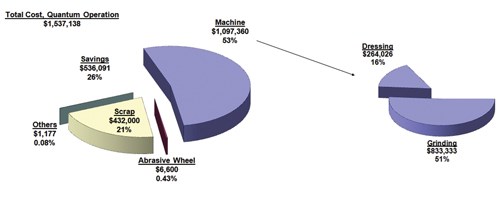

However, because Quantum wheels require less total dressing time, they can provide a cost savings of more than $500,000 (26 percent) over the production run, the company says.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

.png;maxWidth=150)