Redefining Multi-Spindle Machining

The premise of this mega-multi-spindle machine design is to provide a dedicated spindle for every tool required to machine a part. It proves most effective for applications in which tool change takes longer than the cutting operations.

Share

The time it takes for today’s high-performance cutting tools to complete light cuts in light metals can be a fraction of a typical machine’s chip-to-chip tool change time. This fact is most noticeable, and most problematic, when machining medium to large runs of parts that require many simple milling, drilling or tapping operations, such as castings. In these cases, non-value-adding tool change time adds up quickly and chokes throughput.

The new multi-spindle Elha FM 3+X machine, available from Emag LLC (Farmington Hills, Michigan) and introduced to the U.S. market at IMTS 2004, takes in-process tool change time out of the equation. In fact, the machine doesn’t even have a tool carousel or automatic tool changer.

The premise of this design is to provide a live spindle for every tool required to machine a part, and then quickly deliver the part to each tool by way of a four-axis workholding table with a hydraulic clamping mechanism. By moving the part to successive tools in this way, rather than changing multiple tools, the company says that chip-to-chip machining operation changes of less than 1 second are possible. The process is completely automated, with an integral part load/unload arm feeding the workholding table. (The link to an online animation that depicts this machine cutting a part can be found in the Learn More box at the upper right of this article.)

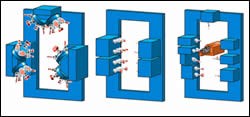

HSK-style spindles mount horizontally in stationary plate modules that “bookend” the machine’s 1,000-mm-tall work zone. This configuration allows chips to fall away from the part during machining and reduces floor space requirements. The machine’s modular design also allows spindle plates to traverse the top of the work zone (in vertical orientation). Spindles may be located close together to minimize table travel between operations, and they can also be strategically spaced for simultaneous drilling of multiple parts or hole patterns.

Having a dedicated spindle for each tool also allows spindle optimization for a tool and machining task with respect to size, speed and power. One to 12 spindles can be driven by a single 20 kW motor, and each machine can have up to nine motors. To date, up to 50 spindles have been installed in one machine.

.jpg;maxWidth=300;quality=90)