Reaming Application Illustrates True Cost of Cutting Tools

Cutting tools have two costs: purchase price and combined cost of all time, effort and extra steps required for a particular tool.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

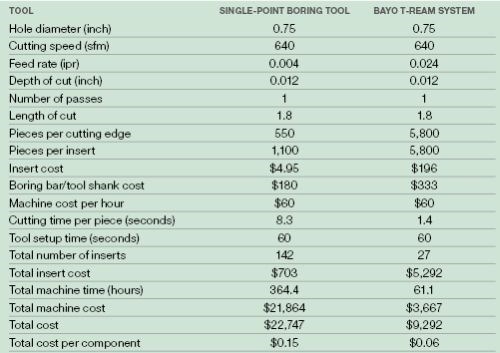

One caveat is that this search for savings often requires a change of thinking. Previously, the injector body manufacturer saw the critical hole as a boring application. The savings came when the company saw it as a reaming application instead. Something similar frequently occurs in milling work, Mr. Edler says. Many facilities can double their metal-removal rate in milling, but doing so requires the counterintuitive step of switching to a high-feed milling tool design that mandates a light depth of cut—lighter than what the shop is taking now. Running this tool at a substantially higher feed rate can more than overcome the lighter cut to save overall cost. In applications such as these, he says, the cost-effective approach often looks very different from the way that a given part or feature has historically been machined.

Related Content

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreCustom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)