Would You Rather Have a Paper Print or a 3D-Printed Prototype?

This custom cutting tool manufacturer uses a 3D printer to provide customers with a physical prototype to view and handle, not just a part print illustrating its complex design.

Share

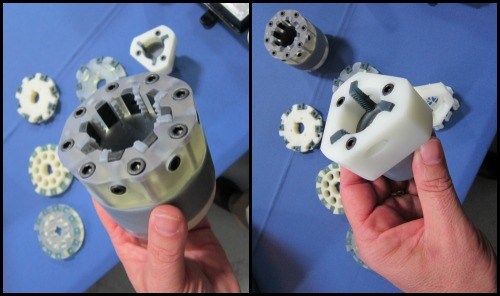

Here are two examples of complex custom tool concepts that Quinn Saw can print and provide to customers so they can more easily comprehend the overall design concept compared to basic illustrations.

Say you need a custom cutting tool that’s likely to cost you a few grand. Would you rather the cutting tool manufacturer you’re considering provide you with a CAD model or printout of the design or, better yet, a 3D-printed prototype of it?

During a recent open house at Hydromat, I got the chance to chat with Troy Frame, product development manager at W.D. Quinn Saw Co., who talked about the value in providing customers with prototypes of custom tools printed from its Formlabs SLA desktop 3D printer.

Started in 1903, Quinn Saw is a single-family-owned business that’s now into its fifth generation. Bill and Joe Zickel are the current owner-operators (4th generation). The company’s core business has always been reconditioning saw blades and manufacturing new ones, but it has since branched out into custom tooling with Troy as the lead designer.

Troy actually worked for Hydromat from 1997 to 2007 as a tooling engineer, engaging with Quinn Saw (Hydromat’s primary blade supplier for its rotary transfer machines) on many projects to improve the barstock sawing process using HSS and carbide-tipped blades. After joining Quinn Saw in 2007, Troy started developing custom tools, such as the printed prototypes shown above, for unique customer applications.

So why the 3D printer for prototypes? Troy says one reason is that his tooling designs often have intricate features and details that are difficult for many people to fully understand and appreciate just looking at paper illustrations. Plus, the people making the purchasing decisions often are not as familiar with the project as their engineering staff, so the printed models enable the decision makers to have something really close to the actual tool in hand, making it easier to comprehend the overall concept.

But another reason had to do with preventing possible interferences. He points to a tool that took 8 weeks to manufacture. Although the customer was happy with how it looked, the tool ultimately didn’t fit into the required space due to an interference with another device in the tight machine environment. This required rushing the tool back and forth between parties for revisions, which was expensive, but Troy notes the biggest impact was the unexpected delay and black eye for providing a tool that was not functional upon receiving it. After resolving the issues and providing a successful tool, Quinn Saw management met to determine how to prevent this from happening again. The idea of using a 3D printer for prototypes was brought up, so Dan Zickel (of the company’s fifth generation) was tasked with sorting through all of the available 3D printer types and options to determine what model was most suitable and cost effective for its needs. After significant reviews of the vast array of machine types, sizes and cost, Dan narrowed it down to the Formlabs Form 1+, which it purchased this past February. This printer offered a suitable printing envelope with a very reasonable cost as well as high printing definition.

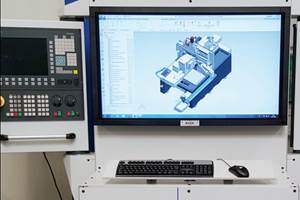

Quinn Saw chose this Formlabs Form 1+ SLA 3D printer because it offered a suitable printing envelope, a very reasonable cost and high printing definition.

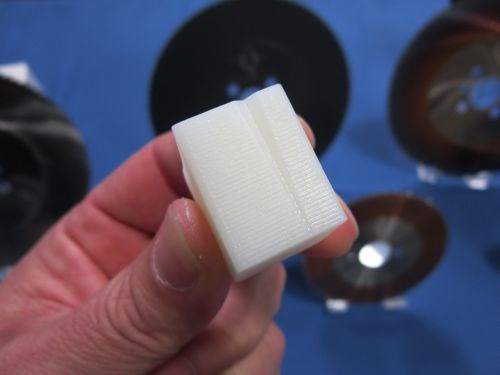

The machine was purchased just before this year’s Precision Machining Technology Show (PMTS) in Columbus, Ohio. This enabled Troy to print and offer models of concepts to show attendees rather than just pictures. Plus, having high-cost actual tooling on a show display table typically isn’t practical or cost effective unless you have a guaranteed avenue in which to sell it afterwards. The 3D printer is also used to scale up small tool features (see the photo below) that would normally require viewing through a magnifying or inspection device, which sometimes isn’t practical at a trade show or in front of a customer.

The company’s 3D printer is also used to scale up small tool features that would otherwise require a magnifying or inspection device to see.

The company sees value in using its 3D printer in other ways, too. For example, Troy says coolant delivery has been a problem for one of Quinn Saw’s grinding machines that has an articulating head. The company is considering printing a new guard with internal coolant ports. Although this design would be costly and impractical to produce via conventional machining, the 3D printer could produce the complex part at little expense. Then after experimenting with the printed guard on the grinding machine, it’d be easy to tweak the design if necessary and simply print another to try.

Troy cautions that while 3D printing technology is helpful, it’s not perfect. Quinn Saw’s 3D printer uses support material during printing that basically snaps off after the part is printed, but leaves small imperfections where it was attached. Those must be removed by filing and or sanding. Plus, there is a fair amount of physical cleanup on printed components to make them all fit precisely and look more presentable—parts don’t just emerge from the resin batch complete and perfect. But in his experience, while the technology is still in its infancy, it is evolving rapidly and so are the machines that do the printing.

Related Content

NMP's Parts Cleaning Systems Pass Upcoming Regulations

PMTS 2023: ITF Parts Washing Equipment machines are designed to help prepare and sustain manufacturers for the upcoming environmental regulations in North America.

Read MoreEAC's IoT Platform Connects Shop Floor With Actionable Data

PMTS 2023: The ThingWorx platform establishes a single source of data for collecting, aggregating and enabling secure and easy access to data for different job roles at multiple locations.

Read MoreMaier Machine Tools' Digital Twin Shortens Development Time

PMTS 2023: Maier’s Virtual Engineering supports developers and engineers in optimally integrating digital twins into their processes.

Read MoreAFT's Semi-Synthetic Coolant Extends Sump Life

Advanced Cool 2200 provides high visibility while machining, keeping the machine and parts clean with no odor issues.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More