Quoting Software Saves Productive Hours, Boosts Client Trust

Paperless Parts has enabled KAD Models and Prototypes to enhance its quoting accuracy and efficiency, simultaneously bolstering the shop’s cybersecurity measures.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

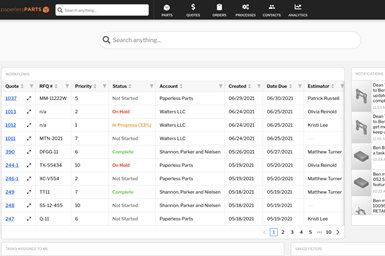

Paperless Parts’ main dashboard gives a general overview of currently active quotes.

Photo Credit: Paperless Parts

KAD Models and Prototypes (KAD) is a specialist in high-quality and fast-turn services for CNC machining, silicone modeling and urethane casting. Founder Brian Kippen and the KAD team provide feedback on designs and recommendations to ensure the highest-possible quality.

The shop has two locations, one in California and the other in Vermont, and began its history using a digital manufacturing network to pick up extra work in slow times and partner with local firms when it was at capacity. While the manufacturing network was able to help KAD grow, the network’s ongoing shift into a global digital ecosystem and focus on high speeds was contrary to the client relationships and high-quality production on which KAD prides itself. Referrals were less likely due to the impersonal nature of the system, quality control became less stringent, cybersecurity grew lax and quote accuracy diminished.

Kippen began to search for an alternative quoting system, preferably one that kept customer relationships in-house and enabled relative independence. This search led him to Paperless Parts.

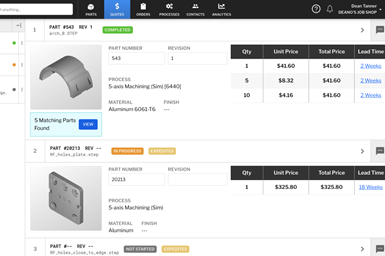

The quote building interface provides in-detail descriptions of the information used in the quoting process, for example, material costs and lead times. Presenting this data to customers helps to build transparency.

Photo Credit: Paperless Parts

Expanding Quoting Options

Kippen was attracted to Paperless Parts because it could help him streamline and automate the quoting process by analyzing the part geometry to suggest pricing, reducing the bulk of administrative work. “Saving 20 hours means making a couple additional thousands of dollars on the shop floor,” he says — and Paperless Parts has saved KAD around 75 hours every month.

Paperless Parts also gives KAD access to custom markup options that enabled the shop to present customers with timetables for a base price and an expedited approach. These expedited options have since grown to 10-15% of Kad’s revenue. “Requoting” options for previously manufactured parts and similar parts prioritize consistent pricing and part quality, and independent control over pricing enables KAD to provide discounts for repeat customers.

Professionally designed digital quote templates within the Paperless Parts ecosystem give KAD the ability to present interactive part previews, part notes, pricing options and an integrated shopping cart to customers. The system also provides tools that allow KAD employees to personalize the quoting process and production partnership for individual customers. “It’s a sales tool in a way, because clients can see how professional we were,” Kippen says. “They can see all my notes in the quote and get the professional experience.”

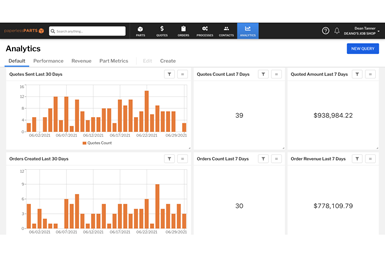

The software’s analytics tool proves users insight into quote activity and visibility into the health of the business as a whole.

Photo Credit: Paperless Parts

Secure, Comprehensive Data

KAD’s data is also now encrypted and secured to ITAR-compliant standards. The shop can mark sensitive parts as export-controlled within Paperless Parts, using the system’s secure file sharing and collaboration capabilities to ensure that the files are never transferred in ways that compromise customers’ intellectual property.

Advanced analytics within Paperless Parts track different customers over time, providing KAD with insight into how buyers do business with them. “If you’re only winning 1% of work from a customer, that time is better served elsewhere,” Kippen says. “The analytics in Paperless Parts helped us optimize our strategy.”

Related Content

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreRead Next

Cybersecurity Becomes a CNC Machining Prerequisite

Management software and information technology partner services prove their worth amid the rollout of defense industry requirements.

Read MoreLet’s Finish Closing the Quoting Gap

Sharing accurate, timely and actionable data is the key to an effective, respectful relationship between a machining job shop and the subcontracting finishing shop. Software that streamlines the quoting process can make this happen.

Read More

.jpg;maxWidth=300;quality=90)