Providing Consistent Tool Engagement in Five Axes

BobCAD-CAM says it is the first to provide a consistent tool-engagement-angle toolpath strategy for two through five-axis operations.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

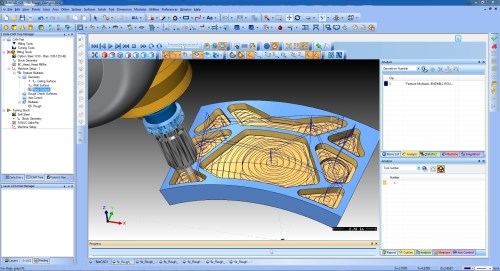

The Adaptive Roughing consistent-tool-engagement-angle tool path is well-suited for features such as this pocket that follows the contour of a cylinder.

BobCAD-CAM is a software developer that has offered affordable, intuitive CAM packages for two- and three-axis machining applications for nearly 30 years. The company recently released its new Version 25 four- and five-axis mill software packages that enable it to offer a single programming platform for an increasing base of customers that are integrating higher-end equipment.

One way users can benefit from these packages is the ability to perform four- and five-axis simultaneous roughing operations. In fact, a new multi-axis tool path available in the company’s four-and five-axis packages makes such simultaneous, multi-axis roughing routines even more efficient. Adaptive Roughing applies the concept of consistent tool engagement angle that previously has been available only for two- and three-axis operations to four- and five-axis simultaneous movements. The company says it is the first to provide a consistent tool-engagement-angle toolpath strategy for two through five-axis operations.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.