PLM App Remedies Data Management Growing Pains

PLM software improved data management at a growing aerospace and defense manufacturer, but it was expensive and difficult to use. An app reduced the system’s cost and made it easier to use.

Share

As companies expand, it can be difficult to scale up systems to keep pace with growth. As Elite Aerospace Group (EAG)’s size and scope increased, it found its legacy system of managing data to be increasingly unwieldy. The company implemented a product lifecycle management (PLM) system from PTC (Needham, Massachusetts), which gave it the document management capabilities, security and accessibility it needed; but cost, ease of use and scalability became a concern. Working with the same company, EAG implemented a “bolt-on” app that improved the efficiency of the PLM system while simultaneously reducing the operational cost of the system by half.

EAG started as a single machine shop in Irvine, California, operating in the aerospace and military sectors. The company initially performed contract manufacturing, managing customer and internal data on network folders and thumb drives. As EAG grew, it established an engineering department responsible for creating engineering data such as 2D drawings and CAD files.

The addition of the engineering department meant that the company suddenly had new document-management requirements that did not exist when it was just a contract manufacturing facility. Companies in the aerospace and military sectors have additional security concerns like international traffic in arms regulations (ITAR) that require them to restrict access, a process that can become unwieldy when data is stored in network folders. Further complicating the matter was the company’s growth. With more than 150 employees, managing access to resources required a lot of effort by IT staff and administrators. The company was wasting time, and employees were having difficulty finding the correct data. Using incorrect data could lead to production errors and impact schedules. EAG began to search for a solution that could address data integrity, revision control, review, validation and security.

The company turned to PLM software to solve the growing pains of data management. Because the company uses multiple CAD systems, it needed a PLM system that would integrate well with all of them. EAG had also grown through acquisition, so its database users were spread across various locations. With future acquisitions likely, the company needed a web-based app that remote users, some without high-speed internet, could access. Cost was another factor, as a significant number of employees needed to use the PLM software for managing engineering and manufacturing data. Finally, the data-migration process was a consideration. For successful integration, the company needed a solution that could access data from multiple network folders across several acquired companies. These criteria led EAG to select PTC’s Windchill PLM system.

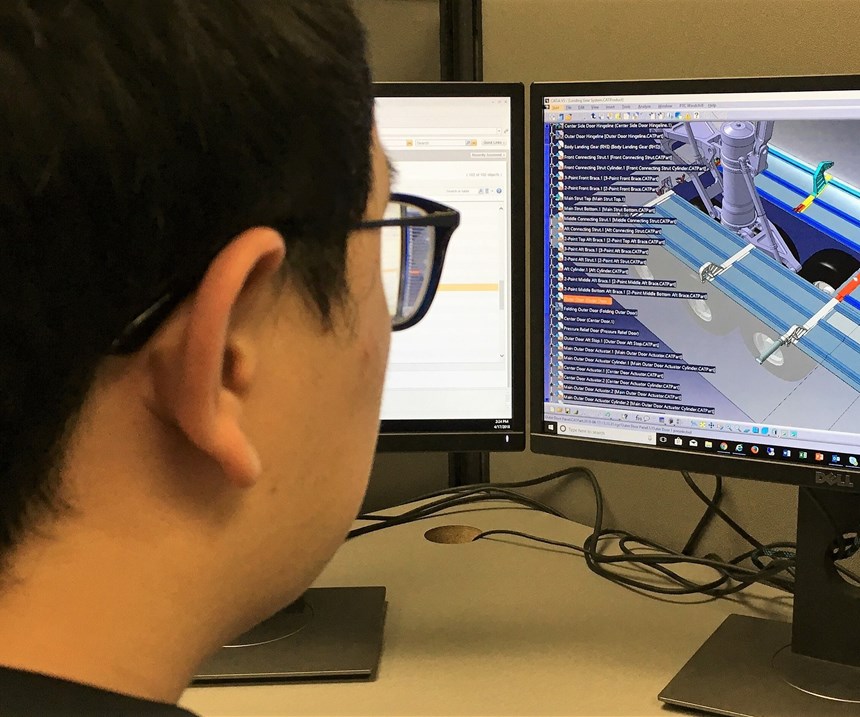

The company says it was able to deploy the PLM system with relative ease and speed; however, because PLM software is typically geared to engineers and content creators, EAG realized that downstream users, like machinists, were having issues using it. Each Windchill user needed training and support, as well as an account and a license. The cost was determined by the number of users, and the company was paying for access for employees who did not know how to use the system. Additionally, data was still stored in multiple locations, so some users were still searching network folders to find data.

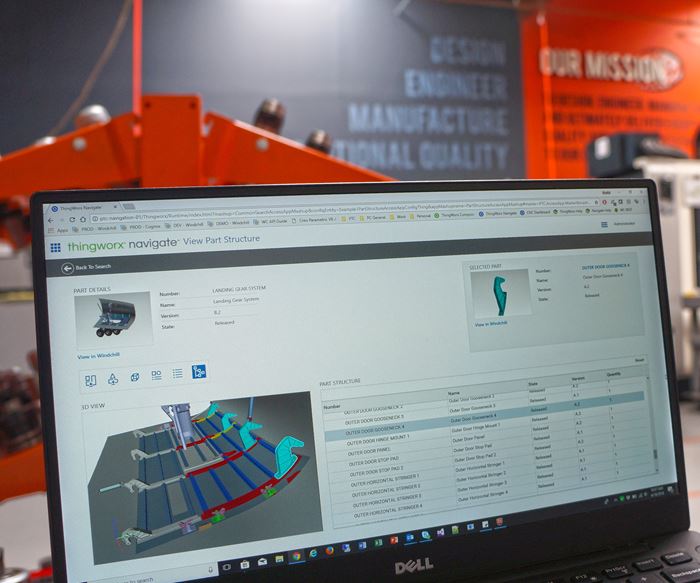

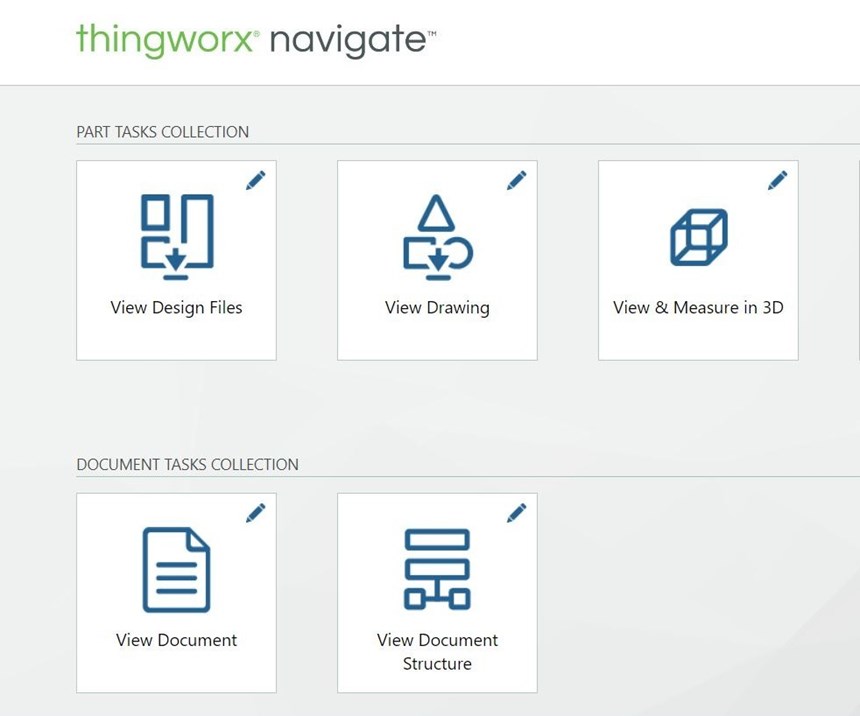

EAG found a solution to these problems in another PTC product, an app called ThingWorx Navigate that “bolts on” to the PLM database. Its clean, simple user interface is designed to look and function like an internet search engine. When users search the database, it gives results from all the connected locations for the data. The design is consistent, with fields and icons located in consistent positions so that users will know where to input and what to click at a glance.

ThingWorx Navigate natively integrates with Windchill; but to connect to other data sources, including other PLM systems, ERP systems and network folders, Navigate may require customization. Because of this, the company initially focused just on setting up Navigate and configuring it with the Windchill PLM system.

The app serves as a single source for users to find all relevant data about a part in the database, including work orders, tool paths and engineering data. Machinists can perform a search based on a part number or work order, and the results enable them to navigate easily to the data they need, as well as reference data that was not previously available to them. The engineering data shows them the finished part, and they can increase the digital resolution to clarify any uncertainties. In addition, an out-of-the-box tool enables users to easily download a bundle of part drawings.

For EAG, one of the key benefits of ThingWorx Navigate is that users do not require a Windchill license, which amounts to a significant cost savings for the company, since Navigate was approximately half the cost of Windchill. In addition to licensing savings, the user interface has reduced training costs. When using Windchill, users required about an hour of training before they could be given access to the PLM. The company also had to provide support for when questions or issues arose. The company says that a simple introduction is sufficient to use Navigate, and PTC provides training videos that reduce follow-up training. Now, employees can start working immediately instead of having to wait for an administrator to provide training. The company says that with the app, its employees are more efficient.

So far, the company has only connected Navigate to Windchill. The next step for EAG is to customize the app and connect it to other data sources so it can access and control data from all its repositories. While this will require some customization, the company says its experience with the software so far has given it confidence that the ROI will be quickly realized.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More