Share

In October of this year, additive manufacturers, 3D printing experts and would-be users of this technology gathered in Cincinnati, Ohio, for the sixth edition of the Additive Manufacturing Conference + Expo. (The event this year was also colocated with the inaugural Top Shops Expo, hosted by Modern Machine Shop and several sister brands.)

Held annually since 2014 (with one skipped year in 2020), the Additive Manufacturing Conference has always had a significant emphasis on production through additive manufacturing (AM). The 2021 program was no different, but this year the issues surrounding AM “production” were noticeably expanded beyond the scope of the 3D printer itself. The message was clear: 3D printing technology is capable of production, but now the entire additive manufacturing ecosystem must evolve to support it.

Shortly after the conference concluded, I recorded an episode of the AM Radio podcast with my cohosts Peter Zelinski and Julia Hider in which we discussed five major themes that emerged during the event. Listen to that conversation below (or wherever you get podcasts), or read on for a brief summary.

- 3D printing represents a solution to supply chain difficulties. Several speakers noted the use of 3D printing in response to shortages caused or exacerbated by the covid-19 pandemic. While printing needed items can be a rapid, first response to a crisis, large production volumes are still largely better suited for processes like injection molding. The right role for 3D printing in the supply chain may be a collaboration with conventional manufacturing, as a means of producing initial runs, spare parts and emergency supplies.

- We don’t have all the people we need in AM. Multiple speakers pointed out gaps in the additive manufacturing workforce related to skills, diversity and mindset. One of the earliest speakers devoted an entire session to describing the culture shifts that need to happen to support AM for production within an established organization; another called out the mental blocks that can prevent engineers from designing effectively for the additive process. A key takeaway? Additive needs more than just additive experts. Machinists, CEOs, materials scientists, accountants, data scientists and more will all need to be involved to advance AM for production.

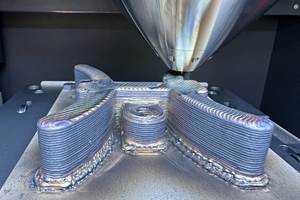

- Additive manufacturing disruption hasn’t slowed. While AM has become an established, accepted method in industries like aerospace and medical, it is still expanding outward. The Cool Parts Showcase, a display area on the expo floor highlighting finalists in a 3D printed part contest, exemplified this trend with entries that included everything from bioprinted replacement bone to orthotic/prosthetic devices to small-scale hydropower systems. Even as it matures, AM continues to disrupt new industries and applications.

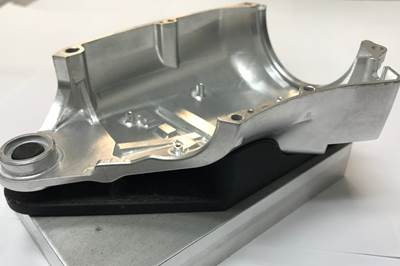

- Tooling is still relevant. Despite a heavy emphasis on direct 3D printing of end-use production parts, tooling continues to be a valuable application. Speakers talked about the injection molding benefits achieved from conformal cooling, the ability to customize large cast components with 3D printed polymer tooling, and the importance of not overlooking “boring” jigs and fixtures in pursuit of adoption.

- It’s time for the cost conversation. Building the business case for AM was top of mind at this year’s conference, compared to past events where technology readiness might have been the primary concern. Speakers discussed comparison tools for evaluating AM versus other manufacturing methods; trends in material pricing; simulation and planning tools; and what will need to happen for additive manufacturing to reach full commercialization at scale.

The next edition of the Additive Manufacturing Conference will take place in September 2022 colocated with IMTS—The International Manufacturing Technology Show.

Related Content

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreJTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read More6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreRead Next

Five 3D Printing Trends Mirrored in Machining

The underlying drivers of additive manufacturing’s advance are increasingly easy to spot on automated CNC machine shop floors.

Read MoreExplore Additive Manufacturing with AM Radio

Additive manufacturing editors Stephanie Hendrixson, Peter Zelinski and Julia Hider talk industrial 3D printing on a new podcast.

Read MoreThe Value of a "Pathfinder Part" for Additive Manufacturing

Implementing additive manufacturing means starting somewhere. Seeking out the right pathfinder part can illustrate valuable lessons about the advantages of this technology.

Read More

.jpg;width=70;height=70;mode=crop)