Overcoming Toolholder Deformation with High-Torque Retention Knobs

At Hansen Engineering Co., toolholder expansion reduced spindle contact, causing a variety of production issues. High-torque retention knobs from JM Performance Products increased productivity and reduced downtime.

Share

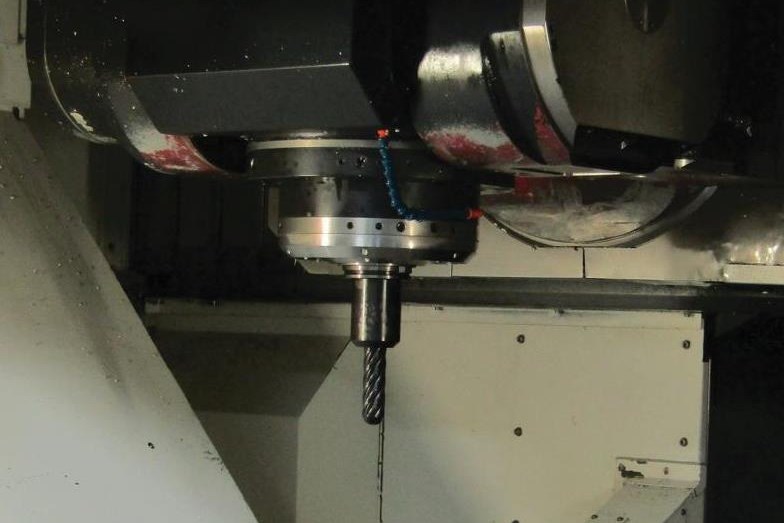

When a toolholder expands, it cannot make full contact with a machine tool’s spindle, causing vibration, chatter, poor tolerances, non-repeatability, poor finishes, shortened tool life, excessive spindle wear and tear, runout, and shallow depths of cut, among other problems. Hansen Engineering Co. (Harbor City, California) remedied its production issues by converting to high-torque retention knobs from JM Performance Products Inc. (Fairport Harbor, Ohio). This reportedly increased the aerospace engineering shop’s productivity by 15 percent and decreased downtime.

Established in 1962, HEC is an approved Air Transport Association supplier of precision-machined multi-axis parts and major structural assemblies. The shop specializes in complex MDI surface geometry, statistical process control and electronic probing of part surfaces. The majority of its high-speed CNC machines operate within a 10,000- to 15,000-rpm range, cutting large blocks of titanium, stainless steel and aluminum for an array of aerospace products.

Over time, the company’s everyday machining operations began to present increased issues. For example, toolholders were getting stuck in the spindle due to deformation factors evidenced by wear marks at the top and bottom of the holders; fretting appeared on contact surfaces; and increasingly long cycles developed. These persistent problems led to increased production shutdowns to allow the machines to cool off for significant periods of time. Additionally, poor finishing and chatter problems were recurring when roughing aluminum, titanium and stainless steel for forging jobs.

When a standard retention knob is installed in a V-flange toolholder, pressure exerted by thread engagement, coupled with the elastic properties of the steel used to manufacture the toolholders, creates a bulge at the small end of the holder. Once expansion occurs, the holder will not pull all the way into the spindle, and the toolholder cannot make contact with upwards of 70 percent of the spindle surface.

Recognizing the design flaw inherent in CNC V-flange tooling that was responsible for costly CNC milling and boring issues, JMPP designed high-torque retention knobs that could be used in existing toolholders to eliminate the bulge. These patented high-torque retention knobs are longer and reach deeper into the holder’s threaded bore than standard knobs. As a result, all thread engagement occurs in a region of the toolholder where there is a thicker cross section of material to resist deformation.

HEC engineering personnel met with JMPP, a manufacturer of CNC mill spindle-optimization products, to learn how its high-torque retention knobs could work with the shop’s 50-taper V-flange toolholders. Intrigued by their potential, HEC initially bought 25 knobs and properly installed them following calculated torque specifications using a retention-knob socket and torque wrench. Immediately, the shop noticed a 5 percent spindle-load decrease using a 3-inch high-feed insert mill running titanium. The company also installed them on an aluminum forging job that had consistently produced chatter problems. Among the tools tested for this job were a 1.25-inch-diameter knuckle rougher and 2-inch-diameter finisher.

“Again, the results were positive, as the chatter was eliminated, and it produced the best finish we have ever seen on these parts,” says Curtis Sampson, shop leadman. “After that, we bought 50 more pieces and immediately noticed improvements all around the table. We’ve been increasing their use over time ever since.”

According to JMPP President John Stoneback, “By significantly increasing the speed of machines via eliminating the problems that were designed into V-flange tooling, conservative estimate savings of 10 to 15 percent can be achieved. The high-torque knobs transform V-flange tooling into the most cost effective, reliable and precise tooling system available.”

Since these initial tests, HEC has progressively converted to high-torque retention knobs in its 14 CNC machines, requiring approximately 120 per machine. Jose Campos, tool crib buyer, says the 15 percent increase in productivity has led to the same rate of decreased downtime due to less change-out of tool cutters across the board.

Mr. Campos praises the knobs’ performance on HEC’s latest Mazak five-axis CNC machining center, which features a 160-inch-long dual-shuttle table. Its toolchanger is designed to run a full table of parts while the other is being loaded to eliminate downtime. The Mazak machines used to make a loud noise when changing tools, he says, but now the machines are much quieter when roughing titanium and stainless steel. The high-torque retention knobs also eliminated fretting of the toolholder shank, he says.

Ultimately, the progressive conversion to JMPP’s high-torque retention knobs has allowed HEC to overcome long-standing productivity issues for its entire fleet of high-speed CNC mills. For its demanding aerospace part production, the retention knobs have shown lower spindle loads, the shop says. Additionally, HEC reports reduced power consumption in roughing titanium and stainless steel, and improved overall tool life. Over the long haul, HEC says it has been able to increase speeds and feeds and deliver better cycle times to realize substantial savings.

“I would like to put a word out to the people who are not quite convinced yet: They (the high-torque retention knobs) are worth the small investment,” Mr. Sampson advises. “You may not want to jump in with both feet, but just try them on a job or two, and I am sure that you will notice improvements. In this competitive world we live in today, we can use a product like these retention knobs. They are something that we can just screw in our tools to give us an upper hand on our competitors.”

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)