Optimizing the Production Path

New scheduling and resource allocation gives this gear manufacturer the flexibility to cut down on shop floor backlogs and bottlenecks.

Share

It doesn’t matter if you’re producing the highest-quality gears if they’re not getting to the customer on time. Many custom gear shops invest in resources to improve quality requirements—such as new machine technology and improved process design—but unpredictable backlogs and bottlenecks can remain difficult to manage.

This was one area that Forest City Gear (FCG), located in Roscoe, Illinois, began reevaluating in early 2013. Instead of looking at on-time delivery from a financial perspective, Director of Manufacturing Jared Lyford began breaking data down in terms of production hours. “It became a question of speed of delivery and our commitment to the customer,” Mr. Lyford says. “Once we started getting a handle on this, it really had a profound effect on efficiency and throughput on the shop floor.”

Two Types of Gear Work

FCG, family owned and operated since 1955, has typically manufactured two types of gears: “cut-teeth-only” and “make-complete.” Cut-teeth-only is exactly as advertised, meaning customers send their blanks to FCG to have the gear made—also known as “operational work.” Make-complete projects, on the other hand, require FCG to create a gear from scratch using the customer’s part print.

For many years, the philosophy at FCG was to manage both value streams using the same shop floor resources. “We were having issues predicting delivery for cut-teeth-only projects,” Mr. Lyford says. “With a make-complete job, you produce a gear from raw material to finished good and can forecast when it goes across certain pieces of equipment. Cut-teeth-only work is more unpredictable, often arriving suddenly and creating a bottleneck.”

The very nature of the drop-in business, he adds, has always been a challenge. It requires the shop to determine what its capacity will be more than two weeks out.

When Mr. Lyford mapped both value streams in terms of revenue, it didn’t tell the whole story of what was happening on the shop floor. So he separated them and examined the jobs in terms of hours allocated both by operation and job type.

“It became clear through our research that both value streams would benefit from their own designated production paths,” Mr. Lyford says.

Surprisingly, the research also suggested that despite its lower price tag, cut-teeth-only work played a much larger role on the shop floor than the FCG team originally thought.

Assigning Equipment

With this information at its disposal, the FCG team took the next step in separating the two types of work, earmarking the best equipment for both, since capability was needed on both sides of the fence.

Mr. Lyford assigned all of the machines that had the most turnkey capabilities and allocated them into the cut-teeth-only value stream. “We didn’t need some of the more dynamic machine capabilities on the make-complete side,” he adds, noting that flexibility and time management became the focal point.

“If the guy up the street is trying to do a spline that has a tooth milled out or a unique profile or a crown—something he can’t do—we need to be able to absorb that business. That’s part of the selling point. By separating the equipment, we can justify which of our capabilities are best suited for the different jobs.”

Almost all of FCG’s equipment is less than 10 years old, so Mr. Lyford had the luxury of selecting specific advanced hobbing, shaping and grinding machines for each job type. Two of FCG’s shaping machines, for example, were separated into make-complete and cut-teeth-only work. The company’s Gleason GP300 S features a backlash-free, direct-drive mechanical shaping head and offers a diverse range of capabilities including back-cutting, front-cutting and face gear attachments, so according to Mr. Lyford, it’s a great fit for cut-teeth projects.

On the other side, he says the Gleason P300 S is better suited for make-complete projects. “It doesn’t need to be as turnkey,” Mr. Lyford says. “We can put an operator in front of it and just do the work. It delivers high levels of productivity.”

Getting More Out of ERP

For many years FCG has been using features of Exact JobBoss, an enterprise resource planning (ERP) software suite catered to custom and make-to-order manufacturers. While the ShopBoss scheduling feature was available to FCG, the shop had never used it. “It’s difficult to use a scheduling feature in any ERP software suite when you’re dealing with drop-in business,” Mr. Lyford says.

Now that the FCG staff knows what machines are being used for each job type, scheduling is much more flexible, especially on the make-complete projects. “If we cut an order now, we know our queue times are set, and we get a very finite schedule of where that job is going to run through the shop and when it will hit what machine. We use that exclusively to schedule each individual work center on the make-complete side,” Mr. Lyford says.

Prior to this new system, he says: “Imagine you’re going to put this spline on this job February 1, and you get three jobs on the back dock next week for the same machine. Now you’re not going to hit your February 1 date. The system as it was just couldn’t deal with things like that.”

The new scheduling system tells supervisors what jobs are going to the work centers for any defined period of time, enabling them to both prepare for jobs and move flexibly if something comes up spontaneously.

On the cut-teeth-only projects, it’s a more manual process. The team created intricate Excel spreadsheets including setup time, efficiency, run time, quantities and more. “As we plug in new jobs, we can see the effect down the line, and this keeps us reactive,” he says.

Impact of a New System

The two production paths have led to faster deliveries, fewer bottlenecks and new incentive programs. “What we have established with these value streams is that the cut-teeth-only side is more reactive and less planned, while the make-complete side is more planned and less reactive.” Mr. Lyford says.

Delivery times have improved significantly under the new system. “When the two value streams were competing for shop floor resources, the cut-teeth only work had a delivery window of three to six weeks. Now it’s more like a two-to-three-week window with a 25-percent improvement for on-time delivery. Those are real numbers,” Mr. Lyford says.

More effective production paths have cleared the way for other exciting projects at FCG. For instance, FCG Special Ops is designed to assist manufacturers facing capacity constraints within the gear industry. Says Rustin Mikel, director of corporate marketing, “Those facing long lead times from gear suppliers or shortages of skilled labor can offload their operational work to Forest City Gear.” The program is designed to quote jobs fast and efficiently, offer free gear inspection and perform additional gear analysis.

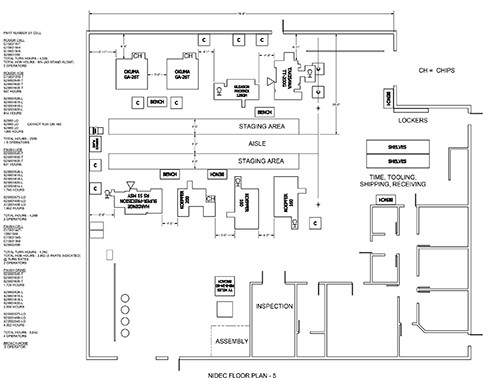

The Roscoe Works building, a second facility behind FCG’s main manufacturing plant, is currently being transformed into a make-complete production cell that will handle high-volume production work. “We’re dedicating equipment for a cellular manufacturing network that will offer turning, rough hobbing, OD grinding, hard turning, skiving, some assembly and broaching,” says CEO Fred Young. “All of these capabilities, with the exception of broaching and hard turning, will be automated.”

Everything the company has learned from separating the work will be used in this new endeavor. “We’ll have some new capabilities as a result of this cell, including skiving to Class 10 and carbide re-hobbing,” Mr. Lyford says.

Identifying Value Streams

The plan at FCG is to continue to evaluate the impact these value streams will have on future business. “My end goal is to totally separate them at some point, from receipt of order all the way to shipping dock,” Mr. Lyford says. “That way, each is self-contained. We want a different person quoting, engineering and ordering for cut-teeth-only and make-complete projects. The pieces are almost in place.”

Quality and inspection is the next area that the company may evaluate to determine if resources should be separated for the different projects. “Our inspection lab can get pretty tied down in make-complete work. If we could find a way to separate this from the cut-teeth projects without additional investment, it would make a great deal of sense,” says Mr. Lyford, adding that deburring is another area that might eventually get mixed into the cut-teeth-only program.

From a business perspective, the gear industry has enough work for FCG to stay competitive in both value streams, whether it’s aerospace, defense, medical, transportation or off-highway work. “We’ve cut gears for a lot of other gear companies, some that offer the same product lines. There is so much overlap in this industry,” Mr. Lyford says. “It does, however, feel like there is a much stronger presence regarding the whole part. Customers don’t want to have different vendors handling different segments if they can help it. It seems like there’s a transition happening in the industry to make the complete part.”

Read Next

10 Things That Caught My Eye at Gear Expo

Check out a slideshow of equipment spotted at the 2013 edition of Gear Expo, the show’s largest edition in more than a decade.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More