One Five-Axis Process, 10 Elements of Automation

The new five-axis machine at Phoenix Proto has a pallet pool with loading system, but there are many other less obvious elements of automation in this precision mold-machining process that are just as essential.

Share

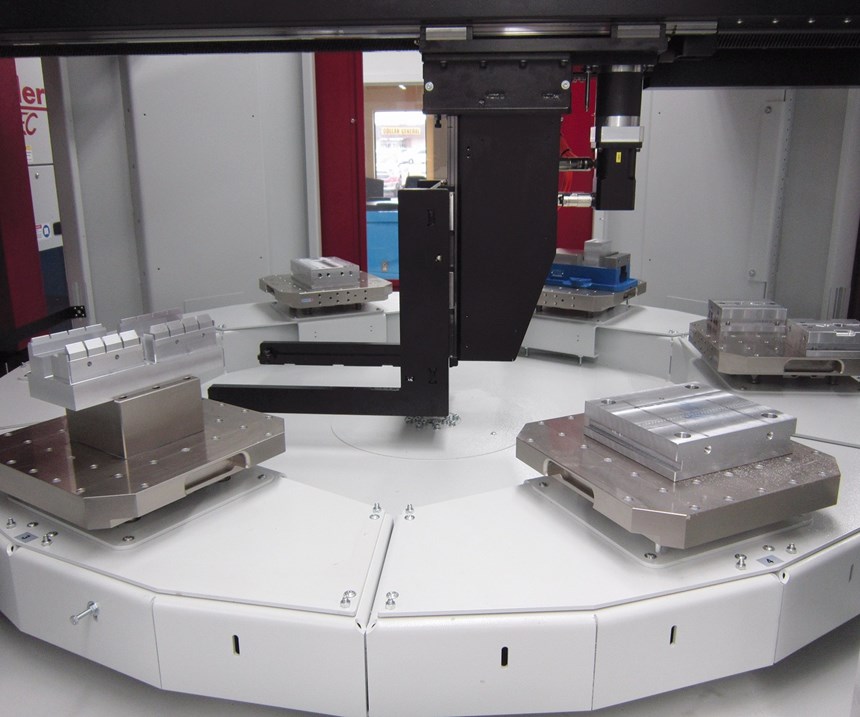

Automation is apparent even to the untrained eye when observing Phoenix Proto’s new five-axis machine with six-station pallet pool and pallet-loading system (the same goes for one of its similarly equipped three-axis machines). That said, there are other, perhaps subtler, elements of automation that comprise the shop’s five-axis process. In fact, it’s these elements that enable the process to repeatedly achieve the tolerances and surface finishes required for the shop’s aluminum mold components while, with minimal if any human intervention, adjusting for the inherent variables that can adversely affect machining precision and throughput.

This point about throughput is important, because the Centreville, Michigan, shop’s goal is to provide assembled aluminum molds to customers within three weeks, so fast turnaround of quality, machined tooling components is imperative.

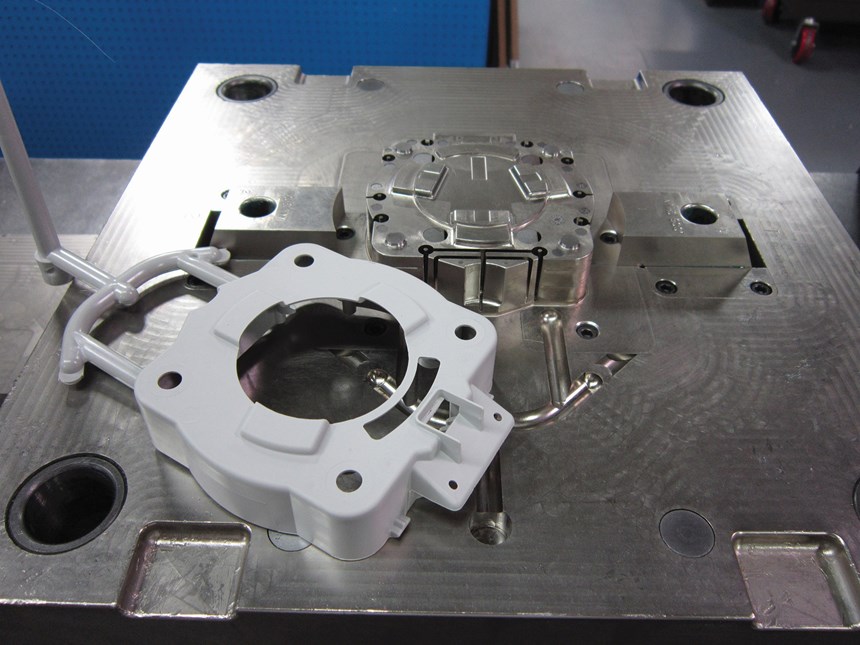

Bob Lammon, company president, says aluminum continues to be commonly used to manufacture prototype and “bridge” tooling (molds used temporarily to enable a company to begin injection molding plastic parts for new products while waiting for the steel production tooling to be completed). However, he is seeing increased interest in aluminum molds used for production in lieu of traditional steel ones.

“Depending on the injection-molded part’s geometry and resin, it is possible to get 50,000 shots out of an uncoated aluminum mold,” Mr. Lammon explains. “In some cases, this might be enough to support production needs. However, by hardening aluminum molds to 54 HRC via technology such as the Nibore hard-nickel coating process we use, it is possible to get 1 million or more shots for a non-abrasive resin, and perhaps 250,000 for an abrasive glass-filled resin.”

The applications for the molds the shop produces are wide ranging, including parts for appliance, automotive, consumer, medical and firearms industries. This leads to a high mix of mold sizes, features and geometries that the machining area must accommodate in short order. Mr. Lammon says the natural solution seemed to be automating a high-speed, five-axis machining process to score long stretches of unattended/lights-out production for the most complex mold components. This it is realizing, as I learned during a recent visit to the Michigan shop.

Automation Additions

Phoenix Proto has three high-speed machines and three conventional CNC machines. The first automated machining center the shop added was a Roeders RXP500 three-axis machine purchased in 2012. This 42,000-rpm, linear-motor machine features an RCE 1 pallet-changing system with a six-station pallet pool. It is now used primarily for machining components such as mold bases and cavity blocks.

Today, almost all the machining of mold cavities and cores is performed on the new five-axis Roeders RXP601DSH with bigger RCE 2 pallet changing system. This, the shop’s first and (at least for now) only five-axis machine, was installed at the beginning of 2016. Like the high-speed, three-axis Roeders, it also has a 42,000-rpm spindle and linear-motor drives with 1-nanometer resolution. Linear motors are key for fast movement, enabling rapid traverse rates of 2,362 ipm. They also offer less friction than ballscrews, which leads to lower power consumption.

The five-axis machine with 21.3- by 25- by 15.7-inch machining envelope and maximum workpiece weight of 440 pounds features a trunnion-style design with A-axis swivel ranging to ±115 degrees. The other rotary motion is provided by the C-axis platter on the trunnion. According to Matt Byers, president of Roeders of America, the trunnion design in which the spindle provides no rotational axis movement tends to be more rigid than alternate five-axis machine platforms to enable heavy cuts. In addition, the low center of gravity for the workpiece keeps inertial forces low to mitigate any tipping or tilting effects during high-speed motion.

Mr. Byers also believes the machine’s proprietary control technology offers advantages for the type of high-speed milling Phoenix Proto performs. Two important parameters to facilitate effective high-speed milling are lookahead and block processing speed. The machine’s PC-based RMS6 CNC offers 10,000-block lookahead and block processing speed of 0.1 milliseconds.

The high throughput made possible by the machine’s fast cycle times using high-speed machining techniques is complemented by all the elements of automation that are incorporated into this process. Here are 10 automation elements I noticed during my visit:

1. Loading system and pallet pool

The five-axis machine’s RCE 2 automatic pallet-changing system has a six-station pallet pool, although the shop will sometimes fixture more than one part on a pallet. Each pallet measures 23.6 by 15.7 inches.

Per Phoenix Proto’s request, the loading system’s gripper was modified. Originally, there could be no part overhang off the edges of the pallet. By modifying the gripper so it picks up from the bottom of the pallet, the system can now load bigger workpieces. Now, part size is limited only by machine capacity, not the loader.

The shop uses Roeders’ job management software to schedule and manage jobs. It tries to schedule long ones to run overnight and weekends, currently running one 12-hour shift five days per week. Alternately, it tries to make sure there are enough shorter-running jobs set up to enable the machine to remain busy on its own.

2. Machine

Five-axis machining is itself a form of automation. There are two types of five-axis processes: contouring and positioning (also known as “3+2”). Phoenix Proto performs 3+2 positioning on this machine 75 percent of the time. For this, the machine uses its two additional rotary axes only to angularly tilt the workpiece and then locks it in that position. After that, it performs what amounts to a three-axis operation in that orientation. One advantage is that this offers the tool access to five sides of a part in one fixturing. This minimizes the number of setups, the number of machines that a part might otherwise have to run across and, thus, the number of times a part is “touched” during production (i.e., it’s “automation”).

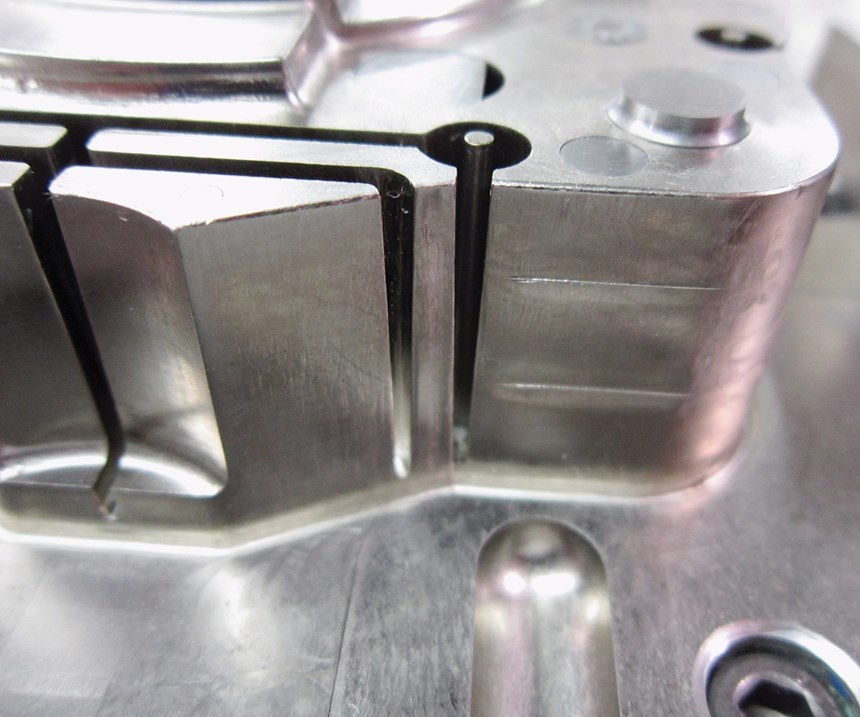

Part-tilting capability via 3+2 also enables tools to reach far into parts to create tricky mold features such as deep ribs. In some cases, this has eliminated secondary sinker EDM operations and the associated need to machine electrodes. Plus, the shrink-fit toolholders used have smaller diameters than collet-style designs to provide additional clearance.

With 3+2, the shop also is able to use shorter, more rigid cutters. Faster, more aggressive cuts can be made using shorter tools without as much risk of vibration or chatter that can occur if longer tools are required. Vibration and chatter can lead to poor surface finishes, which, in Phoenix Proto’s case, would require more manual benchwork for mold components or even secondary EDM work to achieve quality finishes, extending overall production time. The shop is also able to realize improved tool life for ball end mills, because when parts are tilted at different angles, more of the tool’s radius can be used, not just the tip. Machining on other areas of the radius and not the tip (the point where rotational speed is zero) also leads to better surface finishes.

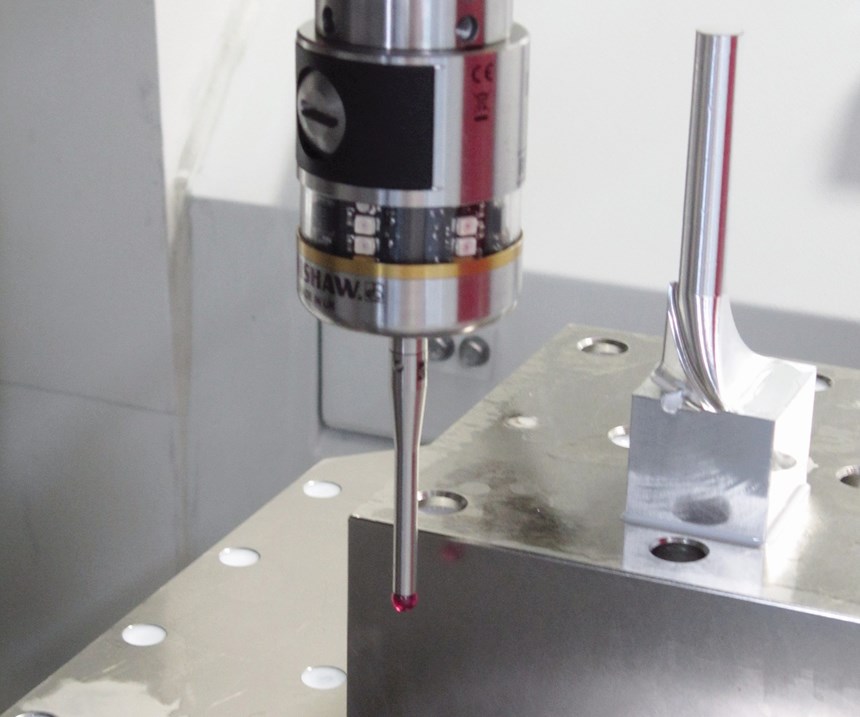

3. Touch-trigger probing

After a new part is loaded into the machine, an automatic probing routine with a touch-trigger probe identifies the location of several points on the part or workholding device to establish the part’s exact location on the machine. The machine’s CNC then automatically adjusts the native work coordinate system to match it. This eliminates manual shimming, part nudging and other time-consuming duties that would otherwise be required to get the part leveled and aligned to perfectly match the machine’s coordinate system.

4. Automatic calibration cycle

The five-axis machine has various cooling channels in its base, rails, carriages and so on, so those components won’t expand due to internal sources of heat. However, to adapt to fluctuations in ambient temperature inside a shop (say from the beginning of a day to the day’s end), an automatic calibration cycle using the touch-trigger probe can be performed.

The Roeders calibration cycle is carried out differently from most other machine tool builders’ processes, Mr. Byers explains. He says those cycles typically call for the pallet currently loaded into the machine to be removed and replaced with another pallet having a tooling ball. This ball is then probed to determine how much of a shift in its location has occurred due to changes in ambient shop temperature. Conversely, the Roeders cycle doesn’t require the existing pallet with workpiece to be removed. The machine has precision-ground prisms on its trunnion-arm casting and C-axis-motor casting that are probed to determine any position changes and, if necessary, automatically compensate for those changes. Phoenix Proto performs this calibration routine once per month unless an issue is noticed and sometimes performs it prior to a critical finishing pass.

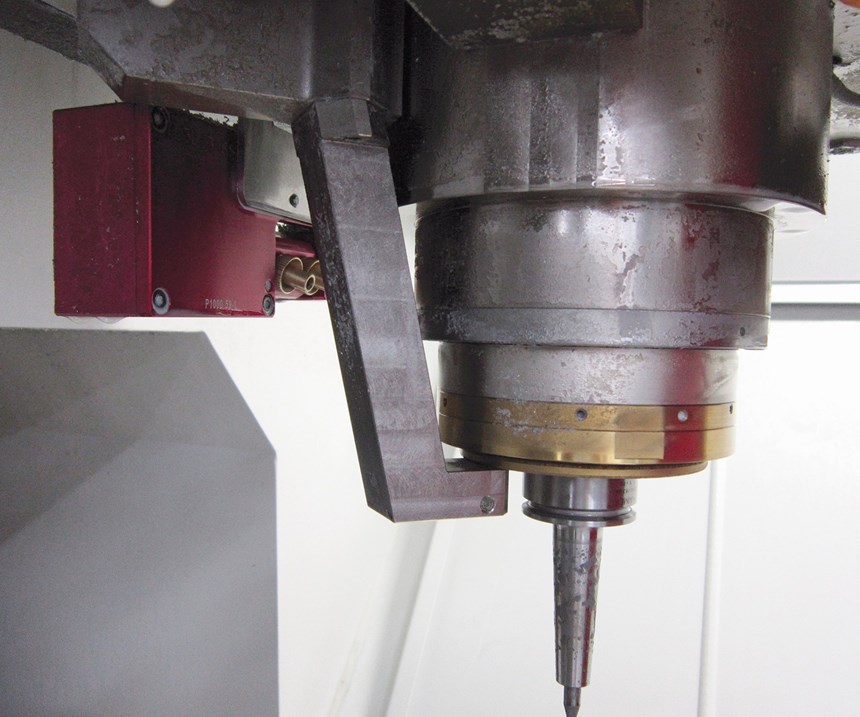

5. Spindle growth compensation

Mr. Byers says some machine tool builders create algorithms for each machine prior to shipping to a customer to approximate how much its spindle will expand at different speeds and run times. However, he notes it is essentially impossible to account for all the various ways the customer might use the machine from one day to the next. Phoenix Proto’s five-axis machine has an optional automatic spindle-compensation system to adapt to spindle expansion (or contraction) in real time. The system uses a non-contact sensor attached to an L-shaped arm positioned near the spindle face (see the photo in the slideshow above). The sensor with nanometer resolution detects how much the spindle expands or contracts during operation and feeds that information back to the CNC to adjust the Z axis up or down to compensate. This is especially important for five-axis operations, because when a part is tilted, spindle growth could affect the tooltip location in all three linear axes, not just in Z. Automatic compensation helps ensure good, consistent surface finishes and blends.

6. On-machine laser tool setting

After each tool change, the new tool’s length and diameter are automatically measured using the on-machine Blum laser tool-setting probe. (The laser probe as well as the touch probe’s calibration tool ball are located outside of the machining area in the toolchanger so they are protected against chips and coolant.) The shop specifies a tolerance band for each tool’s diameter. If the probe detects that a tool’s diameter is out of tolerance, it will not allow machining to be performed using that tool. For example, if a 0.250-inch ball end mill measures ±0.0002 too large or too small, it won’t be used. This applies to the length of the cutter, too.

Prior to this, the laser determines if the tool being changed out has broken. If the tool is broken, but is scheduled to be used on subsequent jobs queued in the pallet pool, it will not stop production on those jobs. “For example, if the tool in ATC position five is found to be broken, the machine will remove the part in which that tool had broken, load the next scheduled job and run that job until it reaches the stage where the tool in station five would be used,” explains Mr. Lammon’s son Scott, the company’s director of operations and one of two who program and set up the five-axis machine. “Then, the machine would remove that part and move on to the next job in the queue. This process would continue for each loaded job.”

7. Coolant nozzle adjustment

Rather than using only conventional flexible coolant nozzles that must be manually positioned, the five-axis machine has a coolant delivery system that automatically adjusts the direction of the coolant stream to the point of the cut, no matter how long the tool is. The nozzles’ direction is adjusted via an M code based on the known length of the next tool that is installed in the spindle.

8. Auto-tilt programming function

Chris Claar is Phoenix Proto’s engineering manager who also programs and sets up the five-axis machine. He says in 2010, the shop performed a time study comparing its previous CAD/CAM software with Cimatron software. “We switched to Cimatron after our study showed a 30 percent programming-time savings compared to the other software,” Mr. Claar explains. “One time-saving feature we appreciate is the five-axis auto-tilt function. Because we have all machine components as well as workpiece, fixturing and tooling 3D-modeled in the software, the auto tilt function is able to determine at what depth the cutter or toolholder would hit the part, and then automatically tilt the part to prevent the crash and enable the operation to continue.” The software also uses those 3D models to enable the programmers to perform offline simulation of machining operations to detect potential crashes.

9. Syntax check

In addition to the programmers running offline simulations in Cimatron for each program, they also use a syntax check function in the Roeders control that automatically proofreads the program and postprocessor to identify any errors before that job is scheduled.

10. Program re-start

If there is a need to stop the machine in the middle of a program, it is not necessary for the programmer to manually go into the posted program, search for the line number at which the machine was stopped and then erase all the code above that so it restarts at the proper position at which it left off. With the Roeders control, an operator simply enters the line number into the command file, and it will automatically read through the program and re-start from there.

Automation Peace of Mind

Although a good deal of thought went into Phoenix Proto’s unattended machining strategy, it realizes that the unexpected can occur. That’s why both the three- and five-axis Roeders machines are set up to send text or email alerts with error messages. It is also possible to remotely log in to the machines’ controls via the online “Team Viewer” software, just as Roeders’ service technicians can perform remote machine diagnostics to get an idea if a component needs to be replaced, if a drive needs to be tuned and so on. (In fact, drive tuning can be performed remotely using this software, Mr. Byers says.)

That said, the shop has another option. It has hung a camera from the ceiling between the two Roeders machines that its programmers can access via their phones to view what’s going on (see the photo in the slideshow at the top of this page). They can pan the camera and zoom in on a machine or its CNC screen to see (and hear) the status of jobs currently running. “As busy as we are now, I will check in on my phone certain times during the night, because a down machine can really put a wrinkle in our schedule,” Mr. Claar says. “It’s just like I’m standing at the machine.”

Related Content

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More