New Control Improves Feed Rates on Remanufactured Legacy Machine

Replacing the original 25-year-old control on an otherwise sound remanufactured VMC enabled a moldmaker to increase feed rates, cut cycle times and increase profitability.

Share

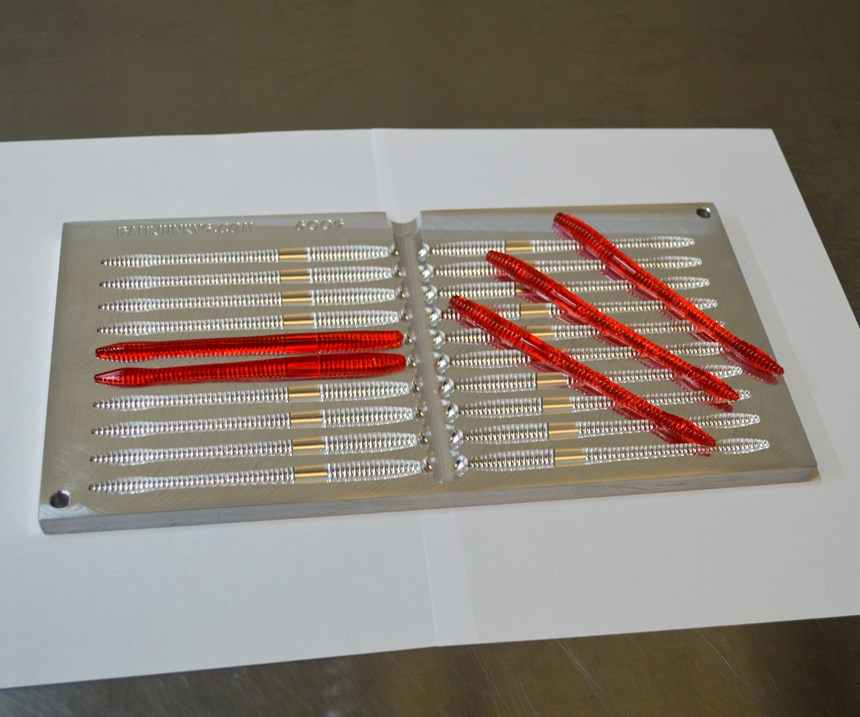

When Baitjunkys purchased a remanufactured machine to produce molds for fishing lures, it needed the old machine to run like new. Mechanically, it did just fine, but its 25-year-old control could not handle higher feed rates without compromising accuracy. A new control from Calmotion (Chatsworth, California) has enabled the machine to reach its full potential, helping the company fill its backlog and increase its profitability.

Limited by Feed Rates

Leonard Smith founded Baitjunkys in 2013. He had grown dissatisfied with the service he was receiving from his mold supplier, so he decided to go into business for himself. He bought a Mach III CNC knee mill, put it in his garage and taught himself how to use it. The company has since moved out of the garage into a commercial space in Lawrenceville, Georgia, near the Lake Lanier reservoir, where the hobbyist- and professional-grade fishing lures produced with Baitjunkys’ molds can be used. In addition to adding more space, Baitjunkys has also added more machines. In addition to the original knee mill, the shop now has a Mazak VTC-20C vertical turning center as well as the remanufactured Fadal 3016 HT vertical machining center (VMC).

“The [Fadal] machine was in good shape mechanically, but it still had the original CNC, which was probably 25 years old at that point,” Mr. Smith says. The fastest he could feed the 0.1875-inch diameter, two-flute end mills used to cut aluminum mold cavities was 50 ipm. At faster feed rates, accuracy suffered. The reduced feed rates were causing him to miss production quotas. Delivery dates slipped, and the company’s backlog grew.

Fishing for Solutions, Catching a New Control

A friend of Mr. Smith’s who had experienced the same issues with his Fadal suggested a solution: a new control from Calmotion. Mr. Smith was already familiar with the company. Shortly after buying the Fadal, he began experiencing slowdowns while drip-feeding large programs through its RS-232 port. By installing one of Calmotion’s USB-to-CNC adapters, he was able to reduce the program load time from roughly 18 minutes to 15 seconds.

Calmotion specializes in providing a range of replacement parts such as amplifiers, motors, cables and other accessories for machine tools, including Fadal machines. One of its products is the 527F CNC, a full-featured digital control replacement. Although Mr. Smith was cash-strapped from buying the machine, he decided to make the investment. “It was the best thing I could have done,” he says.

“There are a large number of Fadal owners whose machines are still functioning well but who need higher processing speeds,” says Calmotion software engineer Glenn de Caussin. The replacement control, which he helped to develop, is a relatively small investment when compared to the cost of purchasing a new machine, and only requires an hour or two of downtime to install. “What’s more, you don’t have to pay us to come install it, or waste time on training or reprogramming,” he adds.

According Mr. de Caussin, the 527F’s processor is 20 to 30 times faster than the ones found on older Fadal machines like the one Baitjunkys owns, thereby enabling increased interpolation rates. The new control also includes several new features not found on the old one, including advanced ramp control, improved block-processing speeds, a flexible memory system for simplified program management and networking capabilities.

The 527F has a multi-processor architecture similar to the legacy Fadal control, but uses newer, faster electronics. Mr. de Caussin says this enables the digital signal processors to execute complex mathematical calculations in a single clock cycle (a single electronic pulse of a CPU). The control also has integral hardware peripherals such as analog-to-digital converters, improved encoder feedback and high-speed communications that were not possible on older units. “These capabilities, not found in the original Fadal control, allow the machine operator to push the iron to its maximum potential,” he says.

Despite Mr. de Caussin’s caution of a couple hours’ downtime, Mr. Smith says he was able to install the new control on his own in about an hour. “If you’re smart enough to program a CNC machine, you’ll have no problem putting in one of these controls,” he says.

Making Adjustments for Faster Cycle Times

With the new control installed, the next step for Mr. Smith was to adjust the feeds and speeds accordingly. “Realistically, I could have just hit cycle start and it would have worked right out of the box,” he says, “but the previous feeds and speeds were so conservative that I had to go through and bump things up.”

With the new control, he was able to increase feed rates to 180 ipm, which has led to a significant improvement in cycle time. “As it stands, my cycle time went from 4.5 hours to just over 2 hours without having to change anything but the feed rate,” he says. He adds that he believes that feed rates of 250 ipm would be possible if he were to switch to a larger cutting tool.

The new control provides some additional benefits beyond the ability to increase feed rates. It accepts his legacy machine programs without reposting or code modifications. Mr. Smith was also able to maintain the postprocessor on his BobCAD-CAM programming system. Also, because the control’s user interface is virtually identical to the old one, he was able to run the machine without additional training. It also increased program storage from 2 megabytes to 16 gigabytes and provides native USB and Ethernet capabilities.

Although the new control was an investment for Mr. Smith, it paid off in the end. “The cost of replacing the control with the Calmotion is the equivalent of two payments on a new machine,” he says. “I recouped my costs within the first few months just on the cycle time reduction. For someone doing production work, it would be an even faster payback.”

Related Content

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More