Nesting Creates a Milling Challenge

This job shop uses remaining steel stock to hold a mated pair of aircraft parts.

Share

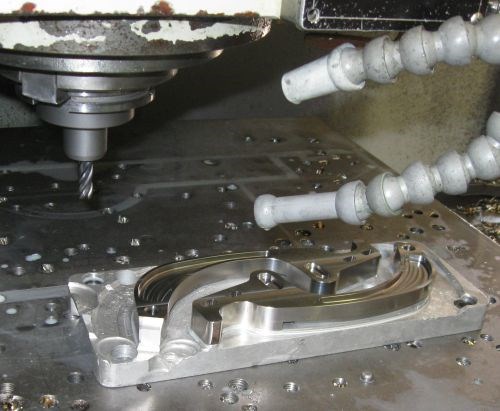

Here is side one of the nested set of parts, with a little of the shape of the parts becoming visible.

Here is side two, with the two parts rising up out of the steel block. The channel between these two parts is a difficult feature to machine efficiently.

Related Content

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

-

Big Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

-

Ceratizit Product Update Enhances Cutting Tool Solutions

The company has updated its MaxiMill 273-08 face mill, WPC – Change Drill, as well as the HyPower Rough and HyPower Access 4.5-degree hydraulic chucks.

.jpg;maxWidth=300;quality=90)