Multitasking For Micro-Finishing

Micro-finishing or superfinishing is traditionally a specialized secondary operation. In the shop, it follows grinding or hard turning as a last surface preparation operation. In many cases, the combination of hard turning and micro-finishing can effectively eliminate grinding.

Share

Micro-finishing or superfinishing is traditionally a specialized secondary operation. In the shop, it follows grinding or hard turning as a last surface preparation operation. In many cases, the combination of hard turning and micro-finishing can effectively eliminate grinding.

Metalcutting processes such as grinding and hard turning tend to be aggressive, high heat generating operations. The cutting action and heat change the metallurgical characteristics of the workpiece. The effect of this cutting and heat combination is called an amorphous zone and is an unstable layer in the metal matrix located on the surface of the workpiece.

Under a micrograph, the amorphous zone looks like a jagged mountain range on the surface of the workpiece. The affected zone is not very deep—it averages 0.0002 to 0.001 inches of penetration—but because of the peaks, it tends to make the contact area between mating parts less stable.

In operation, the motion of two mating surfaces will eliminate the amorphous zone but the result will be a much sloppier tolerance because the sum of the amorphous zones of both surfaces must be added to the initial desired tolerance. Micro-finishing removes the material that forms the peaks, in a cold state, and leaves a plateau-honed finish for mating components to run in. In other words, eliminating the surface peaks allows a better initial fit between mating components.

With emphasis being placed by manufacturers on single-piece flow, manufacturing cells specifically designed for low to medium volume production are becoming increasingly common. Economic viability of these cells is dependent, to a large degree, on machine utilization. Performing more operations on a single machine tool without the need for multiple setups is one key to achieving higher utilization.

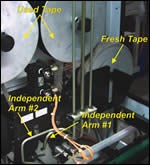

Traditionally, micro-finishing involves rotating and oscillating a workpiece at relatively low speed while a non-compressible abrasive tape, backed by a set of hardened and shaped shoes, presses on the part. The tape is fed through the workzone from a set of reels so that fresh abrasive is available for the micro-finishing process. The used tape is wound on a take-up reel.

This traditional micro-finishing production method uses a single grit abrasive tape each pass in the finishing process. Shops that require a roughing followed by a finishing pass must use two dedicated machines or, stop production and reset a single machine.

Nagel Precision (Ann Arbor, Michigan) has devised a new feed system for its micro-finishing machines that allows two different abrasive tapes to be used simultaneously or sequentially while the workpiece is handled only once. In this system, each shoe has its own tape feed mechanism, complete with individual feed and take-up reels. Each shoe is programmable.

In operation, a coarser abrasive tape can be used on one shoe for aggressive stock removal and a finer tape on the other shoe can be used for finishing. For medium production volume this would eliminate the need for individual roughing and finishing machines. The machine can be fitted with two different size shoes to process different past sizes or multiple diameters on a single part.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More