Multi-spindle Thinking For Machining Center Parts

With 120 multi-spindle screw machines, this job shop naturally looked for technology that applied many of the key principles to non-rotational parts.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreWhat makes a multi-spindle screw machine so efficient and productive? A number of tools are being utilized simultaneously. Several operations can be performed in a single chucking. It takes only seconds to move parts from station to station (the time it takes to index the spindles). Parts are not subjected to a stack-up of tolerances due to multiple chuckings.

About 50 years ago, when Creed Monarch Machine Co. was founded in New Britain, Connecticut, it got its start with single-spindle screw machines the way many screw machine shops began. Creed Monarch specialized in intermediate to high volume production of precision turned parts. Today, the company has moved beyond those roots and is heavily committed to multi-spindle screw machine operations.

It has 120 multi-spindle machines in its modern, 150,000 square-foot facility that is still located in New Britain. The majority of these machines are New Britain Machine models, but there are also about 20 Davenports. A growing number of newer CNC models from several German and Italian builders such as Index, Gildemeister Italiana and Eubama bolster this capability. All of these machines continue to exploit the inherent productivity and efficiency of the multi-spindle concept, serving customers in a range of industries, from automotive to power tools, from hydraulics to electronics.Early on, however, Creed Monarch moved beyond screw machines to find the manufacturing capability it needed to produce many kinds of precision metal components.

Today, the company owns a remarkably wide variety of automated machine tools and production systems for turned and non-turned parts. An equally diverse and exceptional collection of toolroom machines and equipment supports these operations.

“We’re strictly a job shop,” insists Richard E. Creed, president of the company and youngest son of the founder. “We use standard machine tools for custom applications,” he explains. At its peak in 2000, the company employed slightly fewer than 400, but it is now operating comfortably with about 285 employees.

Despite the wide range of workpiece types, the wide range of machine tools in the shop, and the wide range of customers, the company has adhered to the production concepts that make its original multi-spindle machines so effective.

Bridging A Gap

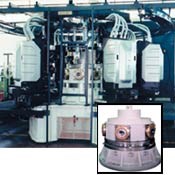

This persistence is best exemplified by the six Imasflex systems the company owns. These unusual rotary transfer machines are not widely known throughout the metalworking industry, but the niche they fill is one of widening interest. The Imasflex is designed to supercede the dedicated transfer line and a line of palletized machining centers. This gap is where a growing number of mid-volume production runs are starting to fall as large manufacturing corporations move to just-in-time production, lean manufacturing and outsourcing.

This trend, however, comes long after Creed Monarch acquired its first machine from Italian builder IMAS (IMAS Transfer S.p.A., a member of the Dell’Orto Group) in 1992. That machine was the very first installation in the United States for the Italian firm, whose main factory is in the region north of Milan. (The U.S. office is in the Chicago suburb of Des Plaines.) Creed Monarch installed its sixth and newest (also the largest) of these systems only last year.

“Creed Monarch and the Imasflex have evolved together,” says Mr. Creed. When his company first approached the builder at the International Manufacturing Technology Show in 1990, the engineers brought along drawings for a system similar in concept to the Imasflex on display. The IMAS people quickly recognized Creed Monarch as a prospective customer in tune with its own innovative thinking. According to Mr. Creed, the builder agreed to incorporate some of his company’s ideas into the original Imasflex design. Over the years, each additional system installed at Creed Monarch has featured refinements and new developments, many of which reflect the needs of customers such as this shop.

“Rotary Transfer” Hardly Descriptive

The builder calls the Imasflex a multipurpose CNC rotary transfer system. While Mr. Creed agrees that this term is technically quite accurate, he believes the production concept this machine embodies is best understood by comparing it to the transfer line on one hand and the palletized machining center on the other.

The transfer line is the ultimate in dedicated high volume production technology. However, in most cases, the transfer line has little or no flexibility. Changes in the workpiece design or provisions for part families are not easily accommodated. Repurposing a transfer line can be prohibitively complex and expensive. Transfer lines make sense for parts made by the millions or the hundreds of thousands for years in a row (and obviously fewer manufacturers are committing for parts in these quantities).

The machining center is the ultimate in flexible production. No two parts produced on a machining center need to be the same, and machine costs for each part will be roughly the same. To achieve higher productivity and somewhat lower cost per part, machining centers can be palletized and the pallets moved from machine to machine for successive operations. Rarely is this approach competitive for mid or high volume production because cycle times are too high. In many cases, refixturing is necessary to reach all sides of the part. The need for refixturing generally rules out high precision applications (and tolerances for work of this kind are getting tighter almost everywhere you look).

“In terms of flexibility, the Imasflex is essentially a group of CNC machining centers positioned around a single large rotary table with highly accurate, indexable chucking fixtures,” says Mr. Creed, “but in terms of productivity, we see it more like one big upright multi-spindle machine.”

Machining Center Flexibility

The key to the machine’s flexibility is the number of CNC machining modules that surround the rotary transfer table. At a glance, the machining modules do resemble column type milling machines without worktables. The spindle head of each module is configured as a four-position turret (six-position on the most recent models) that can be set up in either a vertical or a horizontal orientation. (“We can flip a head [from horizontal to vertical] in about 4 hours,” says Mr. Creed.) Each module operates independently, running its own NC program in three axes. Typically, an Imasflex accommodates seven modules, leaving one station open for part loading and unloading. Creed Monarch’s newest version, a model 500, can accommodate as many as 10 modules, two for each station on the rotary table. This shop’s Model 500 has seven modules altogether.

At this shop, one operator is assigned to each of these machines per shift. Mr. Creed figures that the equivalent number of standard machining centers represented by the Imasflex machining modules would require two to three operators. Machining centers would also require considerably more floor space, a resource that Mr. Creed guards zealously.

Rotary Transfer Productivity

Whereas the CNC machining modules are the key to flexibility on the rotary transfer machines, the key to productivity is the rotary table. Here is where the link to the multi-spindle thinking becomes clearer, Mr. Creed would say. Indexing the rotary table moves the workpieces from machine to machine much like the indexing spindles on a multi move the workpiece from station to station. A programmable logic controller (PLC) coordinates movement of the table and the activities of each machining module.

The rotary table features eight clamping units that the builder calls “satellites.” These satellites can rotate the workpiece independently on a horizontal centerline. The latest versions do so under CNC command for an unlimited number of new positions. Older models, including the older ones at Creed Monarch, have mechanical indexers limited to three additional positions at each station. Either way, it is possible to do five-sided machining and hole drilling at odd angles. Hirth couplings in the satellite are used to maintain very high positioning accuracy.

Creed Monarch has standardized on two-jaw self-centering clamping fixtures on all of its Imasflex machines.

“We get seven spindles cutting metal at the same time on these machines. Parts always hold location and orientation from station to station. There’s no reclamping to sacrifice cycle time or compromise accuracy,” says Mr. Creed. “The game is cycle time and high accuracy,” he remarks, adding that these are the same factors that argue for multi-spindle lathes in turned part applications.

Experience Counts

Almost 10 years of experience with CNC rotary transfer systems has taught Creed Monarch how to maximize its capability. Because the company thoroughly understands these machines and the production concept they embody, Creed Monarch engineers its own fixtures and tooling in house. According to an IMAS spokesperson, all other customers have taken delivery of turnkey systems, taking advantage of the builder’s extensive application engineering staff. This shop’s do-it-yourself approach, however, yields some revealing insights into tooling and fixturing issues.

“These are very expensive machines,” notes Mr. Creed, whose background is in economics. “You don’t want to sacrifice cycle time on operations other equipment can do more efficiently.” For example, blanks for the rotary transfer machines are often produced on multi-spindle machines from bar stock. For another application, one of the Imasflex machines has a CNC lathe and a straddle broaching machine right on the operator’s platform to function as a complete cell. The straddle broach operation machines bosses on the workpiece, a front spindle for a golf cart, creating ideal clamping and locating surfaces on the rotary machine.

“That’s another thing that is critical—workholding. In fact, workholding makes or breaks an application,” Mr. Creed says emphatically. Premachining blanks on rough forgings to create self-qualifying locating surfaces is a common strategy. Clamping has to grip the part securely but not get in the way, one reason why the shop favors the self-centering two-jaw chucks for its machines. These chucks are least likely to interfere when machining on five sides. In addition, clamping forces are more predictable and can be readily addressed in fixture design.

Parts are finished in one clamping, but that clamping has to be equally effective for every station on the machine. Likewise, clamping forces must not create distortions that appear when the part is released from the clamping fixture. Being able to hold concentricity on opposed counterbores to “tenths” is typically the kind of demand the company places on these machines.

High quality cutting tools are another essential that Mr. Creed lists. “High precision results are impossible without high quality tools,” he asserts. Creed Monarch’s extensive toolroom capability includes the jig grinders, wire electrical discharge machines, and inspection equipment. These stand ready to make most of the special form tools required by the banks of screw machines as well as the rotary transfer machines. Several of the toolroom machines are the kinds usually found in the plants of cutting tool OEMs. For example, Creed Monarch has two Ewagmatic six-axis tool grinders capable of producing complete tools from carbide blanks. These machines are largely devoted to regrinding the hundreds of twist drills and counterbores that the shop consumes every week.

On the rotary transfer machines the tooling challenge is to balance operations among the machining modules to obtain nearly equal cycle times, but Mr. Creed says that his manufacturing engineers are adept at this from their experience with multi-spindle operations.

Managing changeovers is one more issue not to be neglected. The rotary transfer machines are designed to facilitate repurposing, but careful planning pays off. The policy at Creed Monarch is to change over when necessary—not sooner, not later. Several of the Imasflex machines are repurposed at 2-week intervals. Several others run “as is” for months.

“These are job shop machines.” Mr. Creek says as a reminder. “Ideally, we want to have several jobs for each machine to keep them fully burdened yet still supply customers with batch shipments as contracted.” Typically, part runs are counted in a few thousands between changeovers. These frequent changeovers take full advantage of the technology’s inherent flexibility.

Finally, there is the issue of training, which Mr. Creed insists, “never goes away.” The company is constantly evaluating employees to identify those with the drive and ability to master both the technical and conceptual aspects of operating sophisticated equipment such as the rotary transfer machines.

The Right Parts

Having a “good eye” for recognizing the kinds of parts that work best on the rotary transfer machines is another skill that comes with experience.

Workpieces requiring numerous but fairly simple operations on many sides are good candidates. According to Mr. Creed, being able to minimize cycle time on the rotary transfer machines is the deciding factor in these cases.

Many candidates for the rotary transfer machines are less obvious. Sometimes it is one operation that is especially difficult to hold repeatably to tight tolerances that makes the rotary transfer machines effective and economical.

“Many parts simply can’t be made to high precision if not produced in one clamping,” says Mr. Creed. “It helps to know what can’t be done reliably on machining centers, too,” he adds. Experience with fixture design comes into play here. Clever workholding is frequently the advantage that makes the rotary transfer approach highly effective. These workpieces often have deceptively simple appearances.

According to Mr. Creed, it is not unusual to achieve a four- to five-fold increase in output per shift when a part is moved to the rotary transfer machines. A part for an automatic assault weapon went from 42 a day on a twin-spindle machining center to 290 a day on the rotary transfer machine. An extruded aluminum roller went from 60 per shift using three machining centers to 450 per shift on the rotary transfer machine.

The Imasflex machines are suitable for aluminum, brass, cast iron and steel. According to Mr. Creed, the newer models have greater rigidity and are more appropriate for larger workpieces in cast iron and steel.

Don’t Stop Thinking

A visit to Creed Monarch’s shop makes it clear that the company has given a lot of thought to what is the best technology for making precision metal components. That one sees a variety of production systems for both turned and non-turned parts shows that the shop has explored many alternatives. As a job shop, the company has consistently opted for non-dedicated systems. Each offers a different balance between flexibility and productivity, but as Mr. Creed points out, there is no one machine that offers the perfect balance in every application.

Applying multi-spindle thinking to machining center parts is one way the shop achieves an especially advantageous balance between flexibility and productivity. Shops with a strictly machining center mentality may have to adjust their own thoughts on part processing to see the wisdom of this approach. In the meantime, however, technology evolves and the balance shifts. New opportunities arise. And so the advice that Creed Monarch follows is to never stop thinking.

Related Content

Industry Analysis: Machining Semiconductor Components

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)