Moldmaker Re-Engineers Tooling Process

Mold and die manufacturer LS Mold (Holland, Michigan) was looking to generate business growth by re-engineering its approach to tooling to secure a strategic advantage over its competition.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Mold and die manufacturer LS Mold (Holland, Michigan) was looking to generate business growth by re-engineering its approach to tooling to secure a strategic advantage over its competition. Central to this restructuring was an initiative to identify and streamline bottlenecks in the design-for-manufacture process. Family-owned LS Mold builds a wide spectrum of molds, ranging in size from very small to 1,000 tons and including plastic injection molds, aluminum die cast tooling, and form and trim dies. The company also performs basic machining services.

“Like most businesses, we’re trying to streamline how we do things and how we communicate,” says David Koning, LS Mold vice president. “Utilizing different software programs has been a tremendous help in not only speeding the pace of job flow through the shop, but also in improving the accuracy of the work. And, of course, that all starts with evaluating a customer’s data and developing a cost quote.”

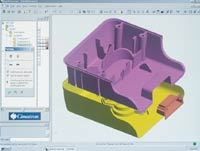

LS Mold found in QuickConcept from Cimatron Technologies (Livonia, Michigan) the necessary catalyst for eliminating restrictive elements to achieve significant time and cost reductions and to develop a lean production process. With QuickConcept in its software arsenal, LS Mold’s CAD/CAM team enjoys quicker turnaround and accuracy in delivering part design, mold design, and manufacturing and reverse engineering services.

“We use QuickConcept in two of the most important initial stages of a project: data evaluation and quoting,” explains Mr. Koning. “When data arrive from a customer, we use QuickConcept to study it along the lines of product development to determine what is really going on with the part. Is the piece drafted correctly? Are there any noticeable slides and lifters? We examine it from a CAD point of view.

“Then, we use QuickConcept to look at the part from a cost estimating standpoint. We study the part along the lines of whether or not what we’re looking at is actually what the customer is asking us to quote,” says Mr. Koning. “We use the software to determine early on if there are problems with the CAD data. If there’s something we’re going to have to correct, we’re able to factor that into our bid from the onset.”

He says QuickConcept was instrumental in streamlining the tool development process because cost estimating specialists no longer had to rely on CAD engineers to gather information. Therefore, the teams didn’t have to operate on the same schedules. Each team member was able to perform an individual function at any time, and the information was presented in a format that all members of the team could understand.

The software also recently enabled LS Mold to deliver significant time and cost reductions when bringing a customer’s line to market. In a fraction of the time previously required, LS Mold performed meticulous data analysis, allowing it to identify flaws in the design data and recommend modifications early on to eliminate several time-intensive development stages and to develop accurate quotes that reflected the true cost of manufacture.

“When we have to deal with drawings, we invest 2, 3 or 4 hours in evaluating the data,” says Mr. Koning. “Using Quick Concept, performing quick part analysis now takes only minutes, versus hours. And, our quoting specialists can call the parts up on their own, without an engineer’s assistance, to determine the parameters of the project.”

QuickConcept transforms complex part CAD designs into easy-to-understand 3D models that can be analyzed, viewed and marked-up by anyone in the tool development process, from shop owners to cost estimators to tool designers¾even those who have never before sat in front of a CAD system.

“We don’t expect our cost estimating specialists to learn CAD material, because that’s not what they do day in and day out. But, using Quick Concept, they are able to extract the information they need in an easy-to-use format,” says Mr. Koning. “The program allows our quoting specialists to shade portions of the drawing and rotate the image to get a better feel for what they’re quoting. And now they can print directly from the program to get an even better handle on what they’re looking at.

“Having the ability to point out problems in very detailed design models more quickly and more accurately allows us to provide meaningful feedback in a timely manner to help spur a project’s success,” Mr. Koning concludes.

Related Content

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)