Mold Manufacturing Automation Leaves No Part Behind

The right mindset, the right five-axis technology and an intuitive approach to palletization help this mold shop extend automated control to the majority of its high-mix work.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreThe worktable on Omega Plastics’ newest, most sophisticated machining center doesn’t have T slots. It doesn’t need them.

From EDM electrodes to mold cavities to the simplest assembly items, virtually every part machined for the company’s plastic injection molds travels from workstation to workstation on a pallet with pre-established work coordinates that eliminate the need to re-indicate. At first, such a system might not seem all that unusual—at least not until one of the shop’s larger, 200-odd-pound mold base blocks is brought into the workzone on one of the same kinds of pallets for complete, single-setup machining. At this point, Omega’s thinking becomes clear: The automated production process in place at this 70,000-square-foot, 75-employee facility is not only reliable enough, but also comprehensive enough that the pallet receiver is the only interface the new machine’s worktable will ever require.

Putting together the three-machine robotic cell at the center of this Clinton Township, Michigan, shop’s production strategy required pushing technology beyond off-the-shelf capability, says Ken Arbic, mold engineering manager. Accommodating heavier steel required modifications to both machine and tooling, with the latter resulting in fixturing so precisely repeatable that some parts can even be removed from and returned to their pallets (or another of the same style) without losing references.

As was the case with implementing automated control in the first place, expanding it to cover the majority of a highly varied, low-volume part mix also required a strong foundation in what many modern mold manufacturers consider a key guiding philosophy. “Everything we do is about achieving a predictable result,” explains Jerry Heckendorn, business development manager. “Whatever the result, we can work with it as long as it’s repeatable.”

Process Takes Precedence

The basic idea is to eliminate the variability associated with the artisanship that defined traditional moldmaking. That means process must take precedence on every job. Specifically, a standardized, cut-to-the-CAD-model process, one that’s developed in advance and that leverages evidence-based practices, parameters and strategies to ensure consistent quality from tool to tool.

Of course, buying into a philosophy is one thing; living it is another. Among the best ways to make a process predictable—to reduce the impact of natural, human-induced variation—is to implement robotics. However, automation can be difficult in an environment like a mold shop where every part is different.

For Omega, that’s arguably even more so. The company was founded in 1984 by Tom Kaczperski, who saw an opportunity to provide quick-turnaround, prototype bridge tooling for customers ranging from entrepreneurs to Fortune 100 medical firms. The company has since expanded its stable of “a la carte” services to include low- to mid-volume production tools, components, molding and assemblies, but high-end prototyping/development and bridge tools still constitute the bulk of the approximately 450 molds produced annually at Omega, Mr. Heckendorn says. Complex by prototyping standards, this tooling produces plastic parts to final specifications, but only a few at a time at most, whereas the more feature-rich production mold might churn out 30, 60 or even upwards of 100 parts per cycle. Such low-cavity work provides little opportunity to machine parts in any significant volume.

One exception to that rule is perhaps the most obvious target for automation at any mold shop: graphite EDM electrodes (Omega produces about 40 per day). Given the labor involved with swapping these components in and out of the toolchanger, the shop’s ram EDM was the first to be integrated with a Workmaster carousel robot purchased from System 3R (a division of GF Machining Solutions) in 2003. Next came a three-axis graphite-machining mill that, once integrated with the robot, could keep the EDM fed with enough electrodes for an entire weekend of completely unattended production. Before long, Omega was taking on additional electrode work from other shops rather than outsourcing its own.

However, the team still wasn’t satisfied. As far as Mr. Arbic and Mr. Heckendorn are concerned, efforts to integrate another machining center for metalcutting set the shop apart from many others with a similar manufacturing philosophy.

Everything on a Pallet

Today, the robotic cell contains a Mitsubishi EA-12V ram EDM from MC Machinery Systems, a Makino V56 three-axis machining center outfitted for cutting graphite, and a five-axis G350 universal machining center from GROB Systems that cuts tool steel and aluminum. The common interface linking these three machines is modular tooling from System 3R, which consists of drawbar-linked chucks and pallets that provide repeatable, three-point referencing to within ±0.002 mm. That’s more than sufficient to shuttle pallets from machine to machine without re-indicating the work at each station, Mr. Arbic says.

However, this strategy proved easier to implement for the EDM and graphite-cutting machines than for the metalcutting mill. For one, the interface between workpiece and pallet wasn’t as rigid as the vises and magnets the shop used previously for milling operations. In addition, EDM operations tend to occur at the end of the process, he explains. That is, parts emerge from the machine complete, and electrodes stay on their pallets throughout their entire lifetimes. In contrast, work slated for the metal mill often has to be sent outside the shop for heat treatment first, and it is more likely to experience mid-stream engineering changes.

Even with sufficient rigidity, that meant taking parts off their pallets and losing all offsets in the process, but no longer. Now, the reference system for any CAM program is intact as soon as the part is mounted on a pallet. In addition to heat-treat and engineering-change situations, this capability is particularly useful for emergency repair or replacement work. “We can put damaged parts back on pallets with intact references, and we can also make new inserts from original CAD files with very high confidence that they’ll fit,” Mr. Heckendorn says. How is this possible? The shop has developed its own, proprietary referencing scheme and taken efforts to eliminate variation within the fixturing system.

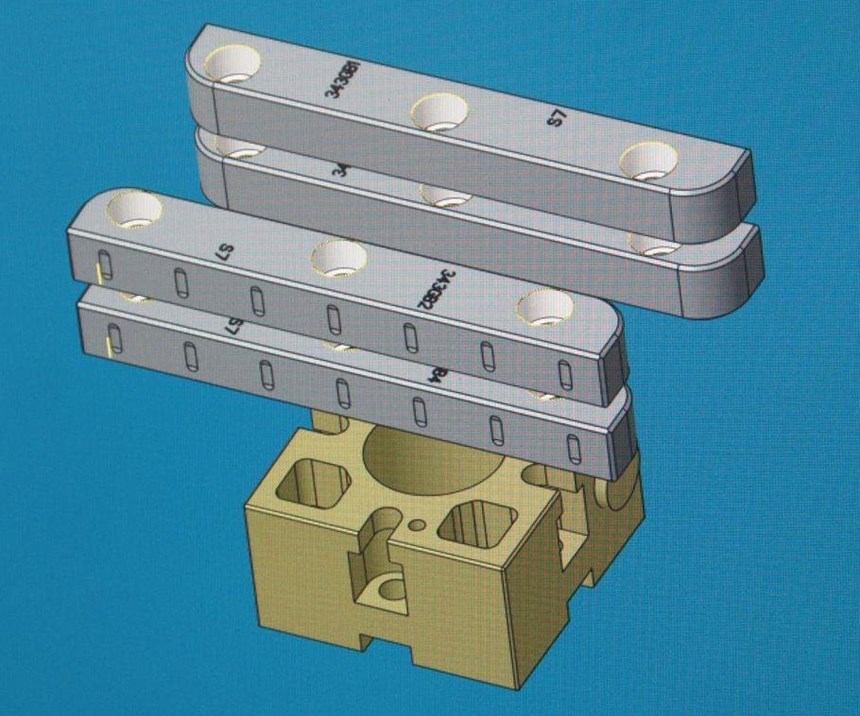

Mr. Arbic emphasizes that there’s nothing lacking about off-the-shelf tooling from System 3R. Rather, the chief concern was the interface between the supplier’s precision-engineered components and the workpiece itself, which varies by user and can’t always be guaranteed by the supplier. At Omega, this interface takes the form of custom, high-precision subpallets in various sizes and configurations, all designed and machined in-house to ensure the fit with the work is just as exacting as the fit with the chuck on the machine table. The shop has also taken steps to keep parts secure when exposed to milling forces that typically exceed anything they would experience during sinker EDM burning. “Making our own subpallets allows us to take advantage of System 3R’s accuracy, but double and triple the size of the component we can mount,” he explains.

All pallets are surface-ground to ensure size varies by no more than 0.0001 inch. Attention was also given to the shape and the pattern of the set of holes linking subpallet to work as well as those linking custom subpallet to System 3R pallet. Experimenting with these and other features has enabled the shop to develop a system that ensures exacting precision and rigidity all the way from chuck to workpiece, Mr. Arbic says. Raw stock is cut from square barstock into blocks measuring 2.5 by 2.5 by 3.5 inches (large enough to cover most work), and pre-machined, pallet-connecting hole patterns provide a mix of horizontal and vertical mounting configurations. Setup personnel simply select the proper block, mount it to a pallet, insert the pallet into the robot carousel, and let the part program do the rest.

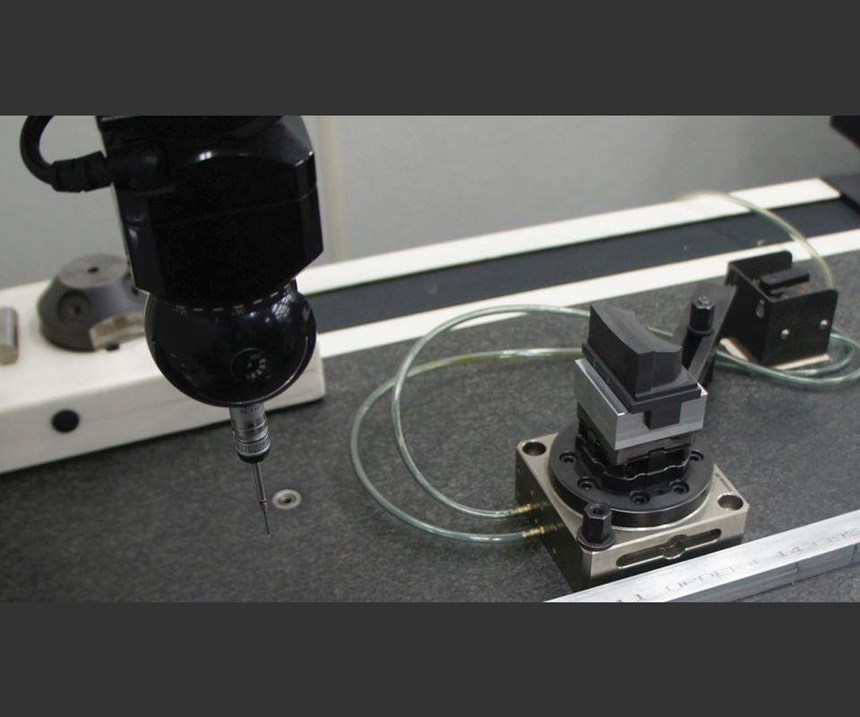

The shop’s common master reference, a custom-designed tooling ball, is just as important as precise fixturing for ensuring parts can removed and placed back into the system without re-alignment, Mr. Arbic says. For every job, this tooling ball is referenced in the CAD file along with a model of the pallet. By locating every feature of every part in relation to the ball geometry, programmers ensure consistent quality across all work. When a pallet moves to a new machine, the only extra step is a brief spindle probe touch-off to confirm not part zero, but the machine’s own zero position. “What (Mr. Arbic and the rest of the team) have done is packaged a method of referencing all workpieces through the entire process, and that scheme is a standard for Omega,” Mr. Heckendorn says.

Getting here wasn’t “rocket science,” Mr. Arbic says about the shop’s work with its pallets and referencing scheme. In fact, he claims any shop with sufficient expertise could likely do the same thing with a system as exacting as System 3R’s. That’s not to suggest such expertise is easy to find, or that applying even basic physics and engineering principles is easy. “It took a lot of trial and error, and having a collaborative internal team of lead moldmakers, tooling engineers, experienced CNC programmers, operators and designers made all the difference,” he says.

The System 3R-based tooling extends standardization and control beyond machines directly tended by the robot. For example, manually loading the shop-floor CMM (coordinate measuring machine) is fast and easy enough that every part, including all electrodes, can be inspected without affecting the shop’s average three- to four-week lead times. Fast, repeatable setups also make it viable to remove parts from the pallets on manually loaded wire EDM machines rather than the cruder sawing process. In addition to being more precise, the EDM can eliminate an extra setup when geometry must be wire-cut into the mounting face of a part anyway. Even the Grob must be loaded manually with the largest mold bases and base plates because the robot’s weight limit is 110 pounds. Nonetheless, a common workholding interface keeps it integrated with the shop’s manufacturing system.

At first, leadership had to enforce adherence to the palletization system, he adds. However, it didn’t take long for crewmembers to begin requesting pallets on their own for virtually everything, including very basic components like custom fixtures, gibs, stripper plates and other minor assembly items. The system’s stability and precision also facilitates mounting long or odd-shaped components that wouldn’t have previously seemed suitable for pallets, such as custom ejector pins. “Pretty much everything here goes on a pallet,” he says.

Scaling Up

The first custom subpallets were developed for the smallest work: 5-by-8-inch core and cavity inserts for the quick-change mold frames favored by company’s bridge tooling customers. Once finalized, the subpallet design was simply scaled up to also cover 7-by-11-, 10-by-15-, and, finally, 18-by-18-inch plates. Today, Omega employs a combination of small, medium and large custom subpallets of various styles as well as multiple variations of System 3R pallets in 54-mm, 70-mm, and 156-mm sizes.

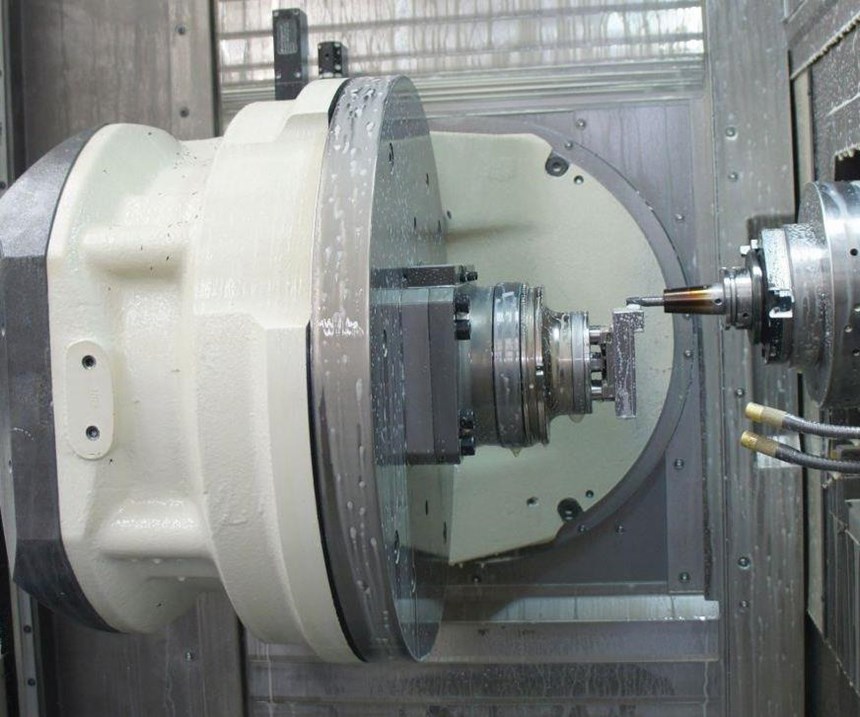

Machining scaled up along with workholding, both in terms of size and sophistication, Mr. Arbic says. The first major change was from a three-axis VMC to one with a two-axis rotary table that enabled 3+2 machining. This eliminated the need for manual setup adjustments to provide spindle access to multiple part faces. However, he says that machine’s rotary table, spindle housing and other components left no room for larger parts like mold bases and base plates, particularly when mounted on pallet stacks. The model in place now, Grob’s G350, suffers no such restrictions, offering the ability to accommodate blocks even larger than the 18-by-18-by-3-inch plates for the largest, standard quick-change frames. With an auto-opening door, a feature requested by Omega and incorporated by Grob, the machine can also be integrated with the robot. That’s a contrast with previous models that required human operators to swap pallets in and out of the table chuck.

The machine’s spacious workzone is thanks largely to its horizontal spindle, which retracts back into the enclosure (including for toolchanges), as well as its one-sided trunnion table, which can flip a full 180 degrees. These two features allow the shop to machine mold base waterlines as deep as 22 inches by drilling to half depth, then flipping the part to bore the rest of the hole from the other side, Mr. Arbic says. Along with carefully programmed 3+2 machining routines, this configuration also makes complex features more accessible than ever before, he adds. That facilitates the use of shorter, more rigid tool assemblies to achieve tighter tolerances and smoother finishes. The machines’ 202-tool-capacity automatic toolchanger (ATC) also prevents tool availability or breakage from limiting lights-out capacity. He adds that the combination of a 26,000-rpm, HSK63A spindle and 63 Nm of torque provide versatility for both heavy material removal and fine finishing operations.

Grob and Grob dealer Merrifield Machinery Solutions (Pontiac, Michigan) deserve much of the credit for getting the machine up and running in the way the shop prefers, Mr. Arbic says. For instance, few users request smooth worktables with nothing but a specific chuck style (a choice that provides a mild chip evacuation advantage while also evidencing the shop’s confidence in its manufacturing strategy). Another example was the addition of a pneumatic amplification system at the back of the machine, a project that also involved consultations with System 3R representatives. Pictured in the slideshow at the top of the article, this system boosts the locking force of the System 3R MacroMagnum automatic table chuck to its maximum. That wouldn’t have been possible with standard shop air.

Altogether, the new machine and modified fixturing have advanced the cell to the point where it can accommodate about 80 percent of all Omega’s work. Based on this shop’s experience, near-comprehensive automation in a high-mix, low-volume environment like a mold shop is anything but out of reach for anyone with not only the expertise, but the will to make it happen.

Related Content

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More